We are a professional Biscuit Machinery Manufacturer with many years of experience in the Biscuit Machinery Industry. Our Vegetable biscuit production line is made with the most advanced technology in the world and has a very high performance.

Biscuit Making Equipment is available in a wide range of sizes and models to process a variety of different types of cookies such as soda cookies, wafers and cookies, etc. The superior performance of the Biscuit Processing Line has been recognized by many Biscuit Manufacturing The Biscuit Processing Line is recognized by Biscuit Manufacturing Units for its superior performance.

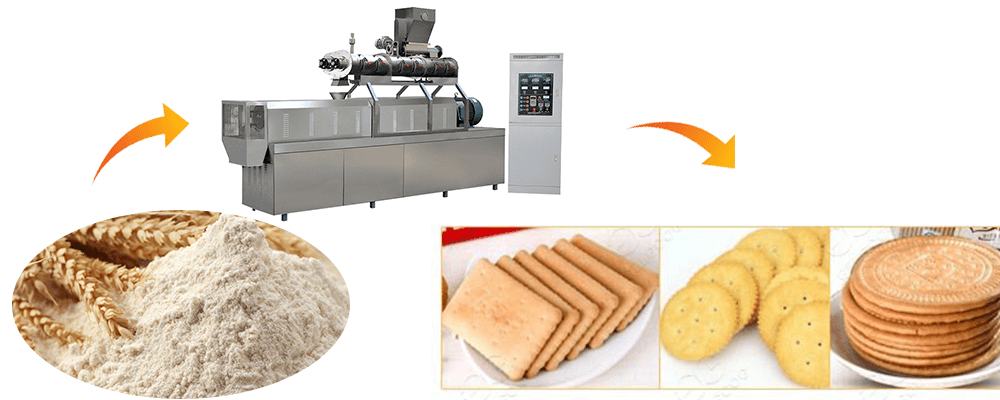

Cookie machine diagram

What is Biscuit Making Machine?

Cookie Making Machine is a fully automatic machine used to produce vegetable cookies, which mainly consists of a combination of Biscuit Equipment such as mixing machine, screw conveyor, forming machine, high temperature oven, oil spraying machine, turning machine, finishing machine, cooling line and packaging machine, etc. Small Biscuit Making Machine has a very Small Biscuit Making Machine has a very advanced Biscuit Manufacturing Process, which can help the majority of Biscuit production factories to further improve their competitiveness in the cookie market.

The production process of Cookie Production Line.

Raw material acceptance→Accessory material acceptance→Batching→Mixing→Mechanical forming→Baking→Cooling→Automatic packaging→Over packing→Storage→Transportation

Mechanical flow chart

Technical parameters of Small Cookie Making Machine.

| Biscuit Manufacturing Machine Price | ||||

|---|---|---|---|---|

| Model | 01 | 02 | 03 | 04 |

| Power | 60kw | 120kw | 180kw | 200kw |

| Voltage | 380v/customizable | 380v/customizable | 380v/customizable | 380v/customizable |

| Capacity | 150-200kg/h | 200-250kg/h | 250-300kg/h | 350-450kg/h |

| Biscuit Making Machine Price | Us$10,000.0 | Us$15,000.0 | Us$20,000.0 | Us$25,000.0 |

| Size | 1.9*0.9*1.6m | 2.0*1.0*1.7m | 2.1*1.1*1.8m | 2.2*1.2*1.9m |

| Above is the latest Automatic Biscuit Making Machine Price for 2022, please contact our Bakery Biscuit Making Machine team for more details. | ||||

The main advantages of Biscuit Making Machine For Factory.

| Features of Automatic Biscuit Making Machine | |

|---|---|

| 1 | The motors and important components of Automatic Biscuit Making Machine are made of international famous brands, with reliable quality and long service life. |

| 2 | The parts in contact with food are made of 304 stainless steel and food grade PU belt, which meet the hygiene and safety standards in the cookie making process. |

| 3 | With fully automated production methods, the Biscuit Making Plant can provide very high productivity and production quality. |

| 4 | The Biscuit Production Line runs smoothly and noiselessly, and the Automatic Biscuit Plant has a better production environment. |

| 5 | Cookies of different shapes, sizes and patterns can be produced according to the needs of Biscuit Manufacturing Plant. |

| 6 | Biscuit Line has reliable performance, high output, low energy consumption, easy maintenance, simple operation and no pollution. |

Finished cookie picture

2021 Customer Order Biscuit Manufacturing Equipment Maker Form:

| Dealed Customer Have Plant Of Commercial Biscuit Making Machine | |

|---|---|

| 1 | Singapore 200kg/h Saving Labor Automatic Biscuit Production Line |

| 2 | 300-500kg/h Canada High Efficiency Biscuit Making Equipment |

| 3 | 1t/h Industry Biscuit Production Line In Indonesia |

| 4 | 800kg/h Customized Factory Biscuit Line For Sale In Russia |

| Dealed Customers Who Repurchase Of Biscuit System At 2021 | |

|---|---|

| 1 | Australia 600kg/h 304 Stainless Steel Biscuit Processing Line |

| 2 | Portugal 1-2t/h Multi-function Biscuit Manufacturing Technology |

| 500kg/h Stepless Speed Adjustment Cookie Making Machine In Pakistan | |

| 4 | 400-500kg/h No Noise Brazil Biscuit Manufacturing Equipment |

1.What is the Biscuit Making Process of the Biscuit System?

The ingredients, such as wheat flour, sugar, salt, eggs, dairy products and bulking agents, are first selected and mixed in a mixer to make a smooth dough. The dough is then rolled into cookies of uniform thickness and then cut into different shapes, with different molds depending on the needs of the Biscuit Project. The cookies are then baked in the oven and cooled in the cooling line before being packed.

2.How to Troubleshoot Commercial Biscuit Making Machine

Vegetable biscuit production line

1. Biscuit sticky bottom: may be due to the cookie is too loose, the internal bonding force is poor, should reduce the amount of bulking agent, or in baking, pay attention to the temperature difference between the rear and middle zones of the oven should not be too large, the rear cooling time can not be too long.

2. Biscuit concave bottom: may be due to too few pin holes on the cookie, cookie expansion degree is not enough and the dough elasticity is too large caused, should increase the needle on the mold, increase the amount of bulking agent and increase the amount of dough improver, etc.

3. Biscuits are still soft and not crispy after cooling: the oven temperature is too high, at this time should be appropriate to reduce the oven temperature and increase the baking time; the back section of the oven exhaust pipe blockage, poor exhaust caused by the temperature difference in the oven is too large, at this time should keep the exhaust smooth.

3.What are the main applications of Biscuit Making Machine For Factory?

The Automatic Biscuit Making Machine is used in a wide range of applications in the cookie market, producing tough cookies and shortbread cookies, such as wafers, cookies, chocolate cookies, sandwich cookies and soda cookies, etc., by simply changing the Biscuit Making Process. The Biscuit Making Process can be changed to produce a full range of cookies, providing a very high economic benefit to the Biscuit production factory.

Vegetable Biscuit Production Line Vido