As a professional automatic biscuit production line manufacturer, our biscuit making machine is well designed and manufactured. The biscuit production line can use wheat flour, butter, sugar, powder, milk powder, bulking agent, eggs, etc. as raw materials, and bakery biscuit machine can be made into different types of biscuits for sale. Bakery biscuit making machine adopts compact structure, high degree of automation, from feeding, three-stage pressing, forming, sugar screening, conveying, waste, and recycling.

How Do You Make a Biscuit Factory Project?

Loyal Industrial automatic biscuit production line can manufacture high quality hard and soft biscuit. From raw material mixing to finished product, automation is completed in one go. Soft biscuit production line can make different types of biscuits such as soft biscuits, hard biscuits, butter biscuits, sandwich biscuits, soda biscuits, animal biscuits, vegetable biscuits, cream biscuits, etc. The procedure for making biscuits can be designed according to the requirements of each customer, such as speed, automatic temperature control, automatic power off alarm. Bakery biscuit making machine oven heating type can be gas, electric, etc.

What Is The Biscuit Manufacturing Technology?

| Biscuit Manufacturing Technology Of Automatic Biscuit Production Line | ||||

|---|---|---|---|---|

| Bakery Biscuit Machine Model | LY225 | LY280 | LY400 | LY600 |

| Power And Voltage | Customize | Customize | Customize | Customize |

| Installed Capacity | 28.5KW | 55KW | 110KW | 220kw |

| Heating Source | Electrical | Electrical | Electrical, Gas | Electrical,Gas |

| Bakery Biscuit Machine Temperature | 200-300℃ | 200-300℃ | 200-300℃ | 200-300℃ |

| Production Capacity | 50~60Kg/h | 100kg/h | 150-200Kg/h | 400-500kg/h |

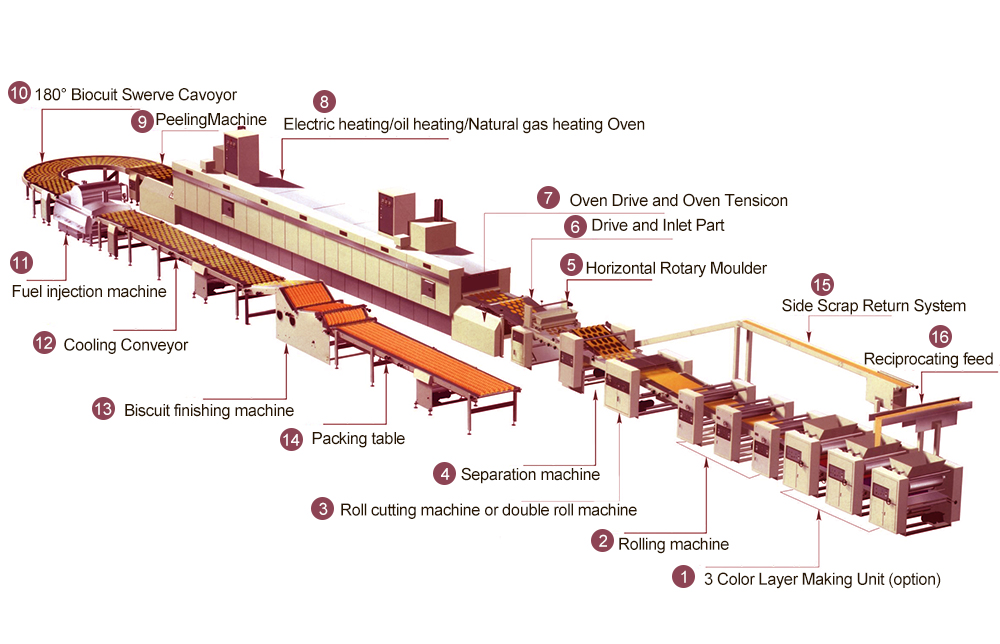

How biscuit is made step by step In Procedure For Making Biscuits ?

| The Baking Process Of Biscuits | |||

|---|---|---|---|

| 1 | Flour Mixer | 4 | Oil Sprayer |

| 2 | Roll Cut Biscuit Form Machine | 5 | Net Belt Cooling Conveyor |

| 3 | Tunnel Oven Of Bakery Biscuit Machine | 6 | Packaging Machine |

| The Biscuit Manufacturing Process Flow Chart Of Hot Sale Biscuit Making Machinery: Flour Mixer—Biscuit Forming Machine—Tunnel Hot Air Circulation Electric Oven—Oil Spraying Machine—Turning Machine—Cooling Line—Biscuit Finishing Machine—Biscuit Sandwiching Machine—Packaging Machine | |||

| The Biscuit Manufacturing Process Flow Chart Of Bakery Biscuit Machine: Flour Mixing—Dough Preparation—Tableting—Rolling Forming—Baking—Oil Spraying Machine—Cooling—Packaging Machine | |||

How Is Advantages Of Multi-Functional Automatic Biscuit Production Line?

| Advantages Of Professional Automatic Biscuit Production Line | |

|---|---|

| 1 | Automatic biscuit production line can easy to operate. |

| 2 | Commercial biscuit making machine can save energy and labor |

| 3 | Biscuit manufacturing process have no noise, no pollution. |

| 4 | Fully automatic and improving production efficiency. |

| 5 | Continuous production, no material loss and save cos. |

| Advantages Of Biscuit Tunnel Oven | |

| 1 | There are three types of tunnel oven electric, gas and diesel oil. It depends on the natural resources of different countries.Some countries is abundant in gas. |

| 2 | The oven of small scale biscuit making machine is full 304 Stainless steel cover, Siemens PLC touch screen control, isolate wood cotton both side is 250mm, top 300mm and bottom is 250mm, hot air circulation system, have automatic alarm device. |

| 3 | Pneumatic automatic tracking and adjust belt and tension. |

| 4 | The size of the oven determines the biscuit capacity. |

Details of Industrial Biscuit Making Machine

What Is The Commercial Biscuit Recipe?

| Ingredients (Measuring Cup Used, 1 Cup = 250 ML) In Automatic Biscuit Production Line | |

|---|---|

| 1 | 1 cup whole wheat flour, 120 grams |

| 2 | ½ cup all purpose flour/maida, about 60 gramsr |

| 3 | 40 grams chilled butter, about 3 tbsp chopped chilled butter, salted or unsalted. |

| 4 | 80 grams plain regular cheese or cheddar cheese, about ½ cup tightly packed grated cheese |

| 5 | 8 tbsp milk |

| 6 | ½ tsp salt or add as required (if using salted butter, then do keep a check on the salt) |

| 7 | ½ tsp black pepper or add as required |

| 8 | ¼ tsp baking soda |

| 9 | ½ tsp baking powder |

| 10 | 1 tsp corn starch (optional) |

| 11 | 2 to 3 tbsp olive oil |

| 12 | some whole wheat flour for dusting |

How Is The Biscuit Mould In Biscuit Manufacturing Process?

1.The biscuit machine is one of the most advantageous products we have independently developed. The shape of the biscuit usually depends on the biscuit mold. The mold can be customized according to your needs.

2.Our company’s biscuit mold is a special plastic material that has high wear resistance to various products used in sugar, bicarbonate, sodium, etc. If you have any machine problems, you are welcome to contact us.

| The Raw Material Of Different Biscuits | ||

|---|---|---|

| 1 | Soft Biscuits | Soft biscuit production line use wheat flour, sugar, and oil as the main raw materials, add loosening agents and other auxiliary materials, and make the shape by cold powder process powder adjustment, roll pressing, roll printing or punching and baking. Most of the shapes are embossed, and the cross-sectional structure Baked food with porous texture and loose taste. Such as butter biscuits, spring onion biscuits, sesame biscuits, meringue biscuits and so on. |

| 2 | Hard Biscuits | Fully automatic biscuit making machine take wheat flour, sugar, and oil as the main raw materials, add loosening agents, improvers and other auxiliary materials, and the patterns made by hot powder process powder adjustment, roll pressing, roll cutting or punching and baking are mostly graves. The appearance of fully automatic biscuit making machine is smooth, the surface is flat, there are pinholes, the section is layered, and the taste is crispy. Such as milk biscuits, vanilla biscuits, egg biscuits, mary biscuits, Boston biscuits and so on. |

| 3 | Cookies | Industrial biscuit making machine use wheat flour, sugar, and dairy products as the main raw materials, add a thinner and other auxiliary materials, and use one of the methods of squeezing, squeezing, and steel wire cutting to form the dough and bake it. The resulting crispy baked food with three-dimensional patterns or regular ripples on the surface and high fat content. |

Which Market Did The Loyal Biscuit Making Equipment Sold?

| Customer Case Of Small Scale Automatic Biscuit Production Line At 2021 | |

|---|---|

| 1 | 100KG/H Thai soft biscuit production line for Thailand customer |

| 2 | 100KG/H small scale biscuit making machine for sale in Uzbekistan |

| 3 | 100KG/H fully automatic biscuit making machine for sale in Nigeria |

| Customer Case Of Industrial Automatic Biscuit Production Line At 2021 | |

| 1 | Industrial biscuit making machine fully automatic 100KG/H in Algerian |

| 2 | 80KG/H industrial fully automatic small scale biscuit making machine for sale in Senegal |

| 3 | 100KG/H industrial biscuit making machine buy online sold in Russia |

| Customer Have Raw Material Case Of Automatic Biscuit Production Line At 2021 | |

| 1 | 500KG/H industrial soft biscuit production line for sale in Bolivia |

| 2 | Mozambique 500KG/H industrial automatic biscuit making machine |

| 3 | 300KG/H fully automatic automatic biscuit production line for sale in Pakistan |

RFQ Of Automatic Biscuit Production Line

1.Is Biscuit Manufacturing Profitable?

If you love to bake and have a keen interest in a soft biscuit production line factory, Shandong Loyal can provide you with hundreds of molds and dozens of craft recipes. Shandong Loyal biscuit machine is one of your best choices. Besides, biscuit machine is a profitable business. Because fundamentally, biscuit production is higher than the traditional bakery market.

2.Which is the best biscuit in India?

| Top 8 Best Selling Biscuits In India, 2021 | |||

|---|---|---|---|

| 1 | Good Day (Britannia) | 5 | Anmol biscuits. |

| 2 | Unibic. | 6 | Googly (Bisk farm) |

| 3 | Bourbon (Britannia) | 7 | Cheese cracker (PriyaGold) |

| 4 | Oreo (Cadbury) | 8 | Glucose biscuits (Sunfeast) |

| We can provide large, medium and small scale biscuit making machine. The soft biscuit production line is reasonably priced, reliable in quality, and professional in service! | |||

3.How biscuits are manufactured?

There are primarily four stages of making the biscuit in a small scale biscuit making machine factory – mixing, forming, baking, and cooling. In the mixing stage, flour, fat, sugar, water and other ingredients are mixed together in the right proportion in large mixers to form the dough.