LOYAL is a professional Biscuit Machinery Manufacturer with over 10 years of experience in the Biscuit Industry and has developed and produced the world renowned Biscuit Manufacturing Plant.

The Biscuit Production Line is fully automated and the Biscuit Manufacturing Equipment can feed, mix, extrude, bake, cool and package in one process.

Our Biscuit Making Equipment has the best performance, both in terms of price and quality, to satisfy Biscuit Manufacturing Units.

We can offer you a very competitive Biscuit Making Machine price and service, and can help you to develop a Biscuit Project and a Biscuit Market Plan to further improve your competitiveness in the biscuit market.

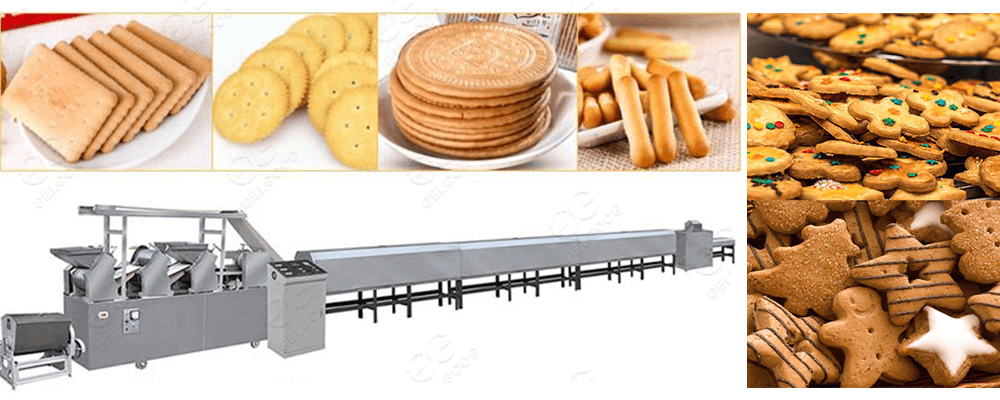

Biscuit Making Machine diagram

What is a Biscuit Making Machine?

The Small Biscuit Making Machine is a fully automated production line consisting of a mixer, screw conveyor, twin-screw extruder, high temperature oven, oiling machine, bending machine, cooling line and packaging machine. The Small Biscuit Making Machine is compact, highly automated and very cost effective, providing the Biscuit Making Plant with very high economic efficiency.

Biscuit Making Machine diagram

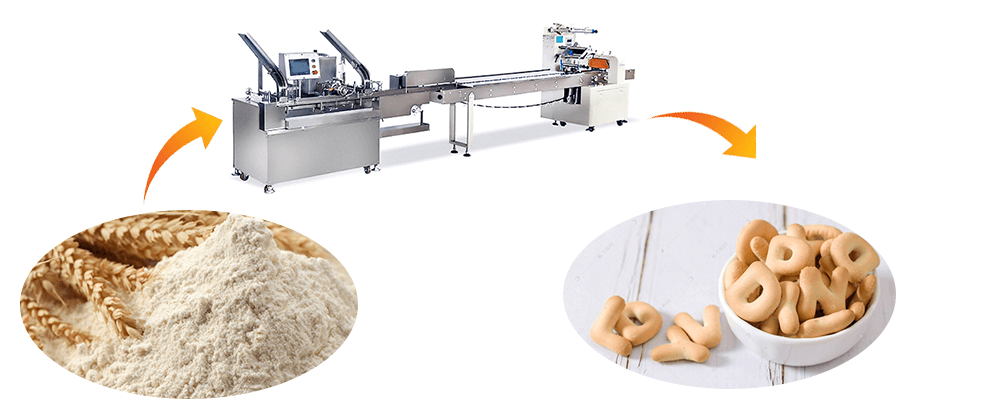

Process flow of the Industrial Biscuit Making Machine.

Mixing → forming → baking → cooling → packaging → finished product.

Biscuit flow diagram

What are the advantages of the Automatic Biscuit Making Machine?

1. Made of food-grade stainless steel, the machine is reliable, robust and easy to clean, and the Biscuit Making Process has high hygiene standards.

2. Compact structure, small footprint, very suitable for small and medium-sized biscuit enterprises Biscuit Project use.

3. The oven has good heat preservation performance and the Biscuit production process is advanced, producing biscuits with full colour and flavour.

4. The high degree of automation can effectively reduce manual operation and further improve Biscuit production technology.

5. Equipped with energy saving devices, it is more energy efficient and cost effective in use.

Biscuit Machine details

Technical parameters of the Automatic Biscuit Making Machine.

| Product Specification of Biscuit Making Machine Price | ||||

|---|---|---|---|---|

| Model | 01 | 02 | 03 | 04 |

| Power | 50kw | 100kw | 150kw | 200kw |

| Voltage | 380v | 380v | 380v | 380v |

| Output | 100-200kg/h | 200-300kg/h | 300-400kg/h | 400-500kg/h |

| Biscuit Making Machine Price | Us$1,000.00 | Us$2,000.00 | Us$3,000.00 | Us$4,000.00 |

| Size | 1.8*0.9*1.5m | 1.9*1.0*1.6m | 2.0*1.1*1.7m | 2.1*1.2*1.8m |

| These are the updated promotional prices for Biscuit Manufacturing Equipment in 2022. For more information please contact our Commercial Biscuit Making Machine team | ||||

Biscuits diagram

2021 Customer Order Biscuit Production Line Maker Form:

| Dealed Customer Have Plant Of Cookie Production Line | |

|---|---|

| 1 | Thailand 200kg/h Automatic Biscuit Manufacturing Equipment |

| 2 | 500-600kg/h Singapore New Factory Price Commercial Biscuit Making Machine |

| 3 | 800kg/h Industrial Biscuit Processing Line For Sale In Canada |

| 4 | Japan 2-3t/h Factory Direct Sales Automatic Biscuit Plant |

| Dealed Customers Who Repurchase Of Automatic Biscuit Production Line At 2021 | |

|---|---|

| 1 | 1t/h Functional Biscuit Line In Indonesia |

| 2 | Turkey 300kg/h High Capacity Biscuit Making Equipment |

| 3 | 600kg/h Brazil Hard And Soft Biscuit Making Machine |

| 4 | 500-700kg/h Cookie Making Technology For Sale In India |

Biscuit diagram

1. What are the main components of the Automatic Biscuit Production Line?

The main components of the Commercial Biscuit Making Machine include a biscuit forming machine, a tunnel type hot air circulation electric baking oven, a greasing machine, a bending machine, a cooling line, a biscuit finishing machine, a biscuit sandwich machine and a packaging table.

These machines can be combined to form a complete Biscuit System with a fully automated production method, which is very practical for Biscuit Making Machine For Factory and can face the increasingly competitive market with higher production efficiency and quality.

2. Types of Biscuit Line in the Market

Biscuit manufacturing processes can be classified as wafer lines, biscuit lines, sandwich biscuit lines, etc.

As the Biscuit Making Process is different for each type of biscuit, the Industrial Biscuit Making Machine has some obvious differences in terms of process.

In terms of the degree of automation, these can be classified as semi-automated biscuit making lines or fully automated biscuit making lines, with fully automated biscuit making lines offering greater output and higher production efficiency, as well as higher prices.

3. How do I maintain my Biscuit Production Line?

1. Small Biscuit Making Machines should be cleaned regularly by removing the screen, but it should be noted that the best time to rinse is when the Industrial Biscuit Making Machine is completely cooled down.

Use a reverse flush to rinse the screen of any contaminants, using a brush to gently scrub the screen if necessary.

2. Pay attention to the removal of debris when cleaning, do a good job of collecting impurities and the site must be cleaned up after the operation.

3. During the Biscuit Making Process, a reasonable time should be set for overhauling and maintenance should be carried out promptly when faults are found to avoid generating bigger faults.