The Automatic Biscuit Production Line is an automated machine developed by our professional team with many years of experience in Biscuit Production Technology.

As a professional Biscuit Line Manufacturer, we have hundreds of molds and dozens of recipes to offer our customers. By changing the molds and recipes, you can use the Biscuit Making Machine to produce a wide range of high-quality biscuits such as cream biscuits, sandwich biscuits, milk biscuits, vegetable biscuits, multi-dimensional biscuits, etc. that are available in the market.

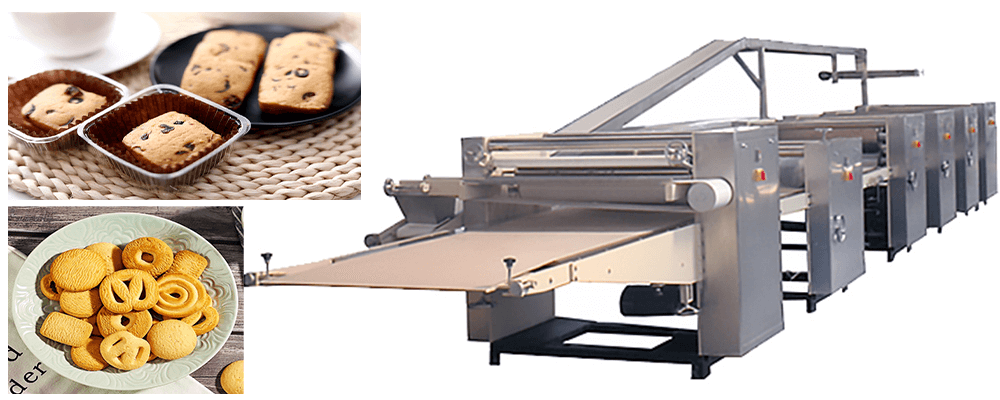

Biscuit diagram

Biscuit Manufacturing Equipment is a compact and precise machine with a unique design that allows for a beautiful shape and an even fire. The Cookie Maker is fully automated from feeding to calendering, moulding, waste recycling, drying, oil spraying and cooling in one go. Biscuit Production is highly automated, clean, pollution-free and noiseless.

Biscuit Machine Diagram

The Automatic Biscuit Production Line includes a mixing machine, a forming machine, a control cabinet, a baking box, an oiling machine, a cooling machine, and many other heat sources such as electricity, gas, and oil. The Biscuit Manufacturing Process machines are made of 304 stainless steel with CE, ISO9001, SGS, and other certifications.

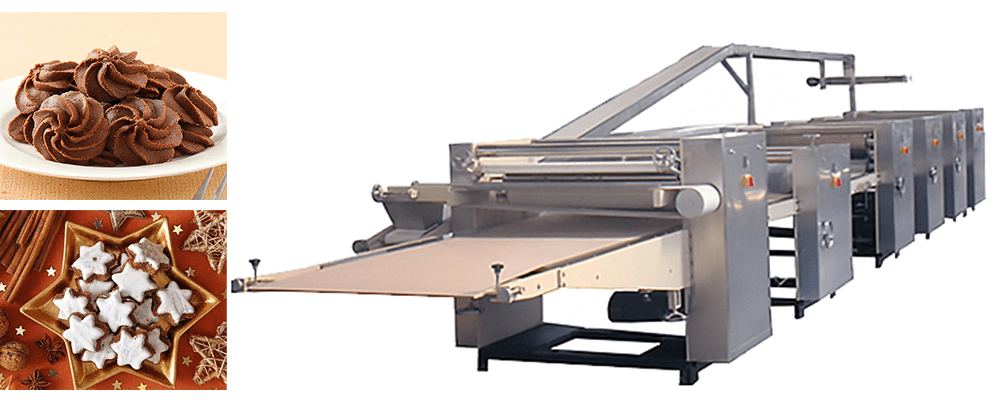

Biscuit machinery diagram

The process flow of the Automatic Biscuit Production Line.

Mixing machine → Forming machine → Roll cutting, roll printing → Tunnel baking oven → Electric/gas heating → Oil spraying machine → Turning machine → Cooling conveyor → Biscuit finishing machine → Sandwich machine → Packaging

Automatic biscuit making machine is professionally manufactured, our biscuit Equipment is safe and reliable, our Automatic Biscuit Manufacturing Equipment can be your best choice; at the same time to ensure that your Cookie Equipment is safe to use, our company will provide you with professional after-sales service.

Biscuit Manufacturing Equipment’s main equipment.

| Main equipment | Mixing machines | Roll cut biscuit forming machines | Roll-printing biscuit forming machines | Oil spraying machine | Turning machines | Cooling machine conveyor | Biscuit finishing machines | High speed pillow type multifunctional automatic packaging machine |

| Dimension(mm) | 1704L×1040W×1750H | 11100L×1400W×2000H | 2380L×1020W×1450H | 2340L×1060W×1680H | 4000L×800W×1000H | 20000L×920W×1000H | 8000L×1080W×1050H | 4000L×950W×1450H |

| Power(kw) | 7.5kw | 16.3kw | 3kw | 3.5kw | 2.2KW | 1.5KW | 4.5KW | 2.5kw |

| Voltage (v) | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 220V/50HZ |

| Production Capacity | 250kg/h | 600kg/h | 780kg/h | 750~800kg/h | 5.5m/min | 650kg/h | 2-6m/min | 50-220包/min |

Machine details diagram

What are the advantages of Automatic Biscuit Production Line?

| The advantages of Automatic biscuit making machine | |

|---|---|

| 1 | The Biscuit Production Line can be arranged in turns to suit the requirements of the site. |

| 2 | The Industrial Biscuit Making Machine is simple, compact and strong, allowing the separation knife to be adjusted to the optimum position, while the Biscuit Making Machine rolls are specially designed to reduce wear and tear and uneven production. |

| 3 | The Biscuit Making Plant has a damp-proofing system with adjustment valves to control the temperature and humidity in the furnace. |

| 4 | Biscuit Manufacturing Equipment furnace with electric heat indicator for improved utilization of electric heating elements and automated control and production. |

| 5 | Biscuit Processing Line oil spraying machine is equipped with imported frequency converter for five-stage speed adjustment to achieve energy saving while maintaining a stable speed. |

| 6 | Biscuit Making Machine turning machine can also automatically adjust speed according to the requirements of different biscuit making, keeping the biscuits neatly arranged, reliable production and easy installation. |

Biscuit diagram

2021 Customer Order Biscuit Production Line Maker Form:

| Dealed Customer Have Plant Of Automatic biscuit making machine | |

|---|---|

| 1 | Russia 600kg/h Automatic Electric Industrial Biscuit Production |

| 2 | Thailand 400-500kg/h China Ce Manufactory Biscuit Production Line |

| 3 | 2t/h Full Automatic Biscuit Manufacturing Plant Thailand |

| 4 | 700kg/h Professional Automatic Biscuit Plant For Sale In France |

| Dealed Customers Who Repurchase Of Biscuit Making Plant At 2021 | |

|---|---|

| 1 | 700kg/h high Quality Automatic Biscuit Production Line Technology for Germany |

| 2 | 400-600kg/h Easy Operation Biscuit Making Line in South Korea |

| 3 | 800kg/h Best Price Biscuit Making Machine In Canada Factory |

| 4 | 1-2t/h Energy Saving Industrial Biscuit Making Machine for Myanmar |

1. What are the features of the Automatic Biscuit Production Line?

1. The Commercial Biscuit Making Machine is fully automated, with automatic temperature control, baking, conveying, oiling and cooling.

2. The Automatic Biscuit Production Line can be adjusted to any thickness and can produce both tough and crisp biscuits with its dual purpose head.

3. The Biscuit Making Process allows the speed of the machine to be adjusted at will, with automatic power failure and alarm for power leakage.

4. High performance and cost effectiveness, low investment and low risk.

2. What are the raw materials of the Biscuit Manufacturing Process?

The main ingredients of the Biscuit Manufacturing Process are wheat flour and a number of supplementary ingredients such as sugar, fats, eggs and dairy.

For Type Of Biscuits, the sugar and fats are lower, with sugar generally below 30% and oil below 20%, while for shortbread biscuits, the amount of flour is between 14% and 30%. There are also differences in the amount of ingredients used for each type of biscuit, so if you are making your own at home, you will need to be aware of the amount.

3. How to arrange the Biscuit Making Plant?

The Automatic Biscuit Plant varies according to the specific production process, but in general there are several workshops for ingredients, mixing, forming, baking, cooling and packaging.

1. Sugar melting room: melting sugar and preparing syrup. It should be located next to the aisle of the Biscuit Making Plant to facilitate the input of raw materials.

The room is hot and needs to be equipped with exhaust fans to dissipate the heat, and there should be enough space to stack the ingredients.

2. Forming room: This contains the powder mixer and forming machine equipment. Space should be left on both sides of the forming machine in the Biscuit Factory for operation, and good lighting and light should be maintained to allow for observation of the suitability of the material.

3. Baking room: Contains the biscuit baking oven, with sufficient space adjacent to the oven for the installation and removal of electric heating elements.

4. Cooling room: cooling of the finished biscuit products, heat dissipation facilities should be good and there should not be much moisture to avoid affecting the quality of the biscuit. The control panel should be separated from the heat source to ensure normal operation.

5. Packing room: The Biscuit Manufacturing Workshop should have good sanitary conditions and adequate lighting.