We are a biscuit machine manufacturer with many years of experience in Biscuit Machine Manufacturing and a comprehensive and detailed knowledge of Biscuit Maker Production Technology, producing a range of Fully Automated Biscuit Makers and with a high reputation for Cookie Maker, which is available worldwide.

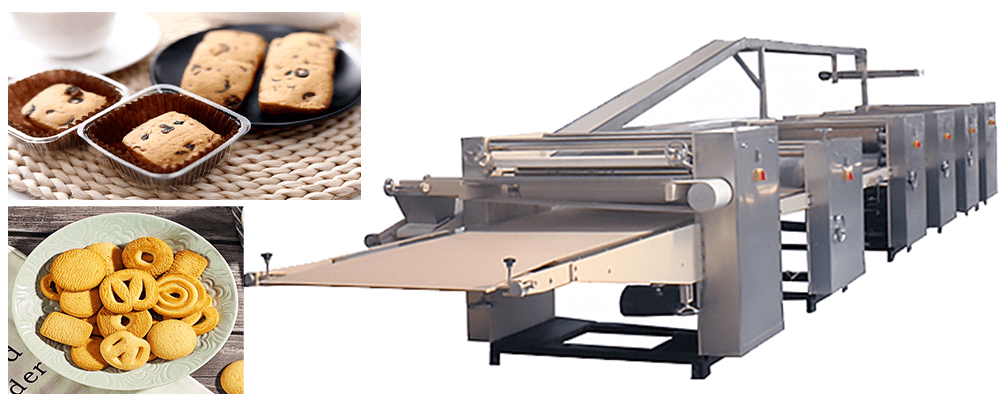

Biscuit machinery diagram

The Automatic Biscuit Machine is controlled by a CPU module and driven by a back-mounted motor, with a compact structure and a high degree of automation. With our Biscuit Manufacturing Equipment, we can produce all kinds of Milk Biscuit shapes.

Biscuit Chart

What are the advantages of the Milk Biscuits Machine Production Line?

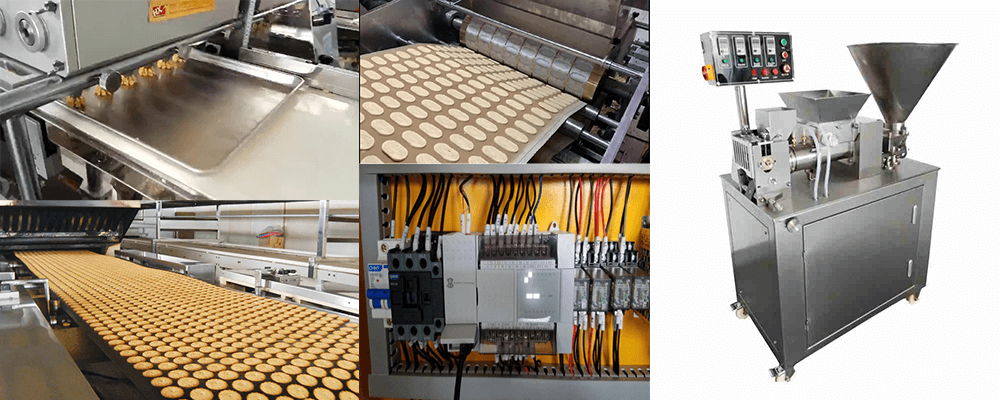

1.The Automatic Biscuit Production Workshop is clean and hygienic and meets food safety standards.

2.The Biscuit Production Line is a mechatronic machine, which greatly saves time and costs in Biscuit Production and increases production efficiency.

3.Biscuit Processing Equipment uses programmed controls for smooth operation and infinitely variable speed control as required.

4.The Biscuit Processing Line is a complete range of equipment with a high degree of machine interplay, capable of producing a wide range of popular biscuits such as cream biscuits, caramel biscuits and soft biscuits.

Biscuit machine diagram

What types of biscuits can be produced by the Automatic Biscuit Making Machine?

The Biscuit Manufacturing Process is based on wheat flour as the main raw material, together with auxiliary ingredients such as sugar, oils, proteins and dairy products. Depending on the mould and recipe process, two main types of biscuits can be produced: tough biscuits and shortbread biscuits, as well as biscuits, sandwich biscuits, soda biscuits, egg round biscuits and other types of biscuits.

| Types of biscuits that can be produced by Biscuit Manufacturing Equipment | ||

|---|---|---|

| 1 | Tough biscuits | Finished Biscuit has a concave flower shape, smooth, flat surface with pinholes, a layered section and a crunchy texture. |

| 2 | Shortbread biscuits | Finished Biscuit has a cabochon surface and a porous structure in section, with a looser texture. |

| 3 | Soda Crackers | Also known as fermented biscuits and chocolate racks, they are fermented products with a characteristic flavour and a crunchy texture, and are available in sweet and salty flavors depending on the recipe. |

| 4 | Biscuits | Biscuit Baking Finished Products have a three-dimensional pattern or regular corrugation on the surface, and are formed by extrusion, extrusion strips, steel wire knot cutting and other methods, and have a high grease content. |

| 5 | Sandwich biscuits | Sandwich Baking Cookies are biscuits with a variety of sandwich ingredients, mainly sugar, fat or jam, added between them. |

| 6 | Egg Round Biscuits | Commonly known as egg-based biscuits, the main ingredients are wheat flour, sugar and eggs, with flavorings in the auxiliary ingredients, and are made by whisking, battering, pouring and baking to create crunchy Baking Cookies. |

What are the parameters of the Industrial Milk Cookie Machine?

| Equipment parameters of Biscuit Manufacturing Equipment | |||||

|---|---|---|---|---|---|

| Biscuit Making Machine models | Power capacity (kw) | Baking temperature (°C) | Production capacity (kg/h) | Dimensions (L x W x H) (mm) | Biscuit Making Machine Price (USA$) |

| 225 | 30 | 200-300 | 52 | 18000 x 600 x 1500 | 16500 |

| 280 | 60 | 200-300 | 110 | 28000 x 800 x 1500 | 20500 |

| 400 | 100 | 200-300 | 220 | 48000 x 1000 x 1500 | 23000 |

| 600 | 180 | 200-300 | 540 | 76000 x 1200 x 1750 | 26000 |

| 1000 | 300 | 200-300 | 1000 | 103000 x 1850 x 2450 | 32000 |

| Automatic Biscuit Production Line prices are the latest promotional prices for 2022, please ask our Biscuit Manufacturing Technology team any other questions. | |||||

Our Biscuit Maker equipment is reliable, safe and has a good after-sales guarantee, so it is popular in the domestic and international markets and is sold all over the world. We look forward to working with you.

2021 Butter Biscuit Making Machine Customer Deal Case:

| 2021Case studies of customers who sold Biscuit Making Machine in 2007 | |

|---|---|

| 1 | Indonesia 500kg/h Industrial Small Cookie Making Machine |

| 2 | France 6500-00kg/h Mini Biscuit Making Machine |

| 3 | Singapore 2t/h Full Automatic Biscuit Manufacturing Equipment |

| 4 | Germany 600kg/h Professional Cookie Making Machine |

| 2021 Customer Repurchase of Automatic Biscuit Making Machine case | |

|---|---|

| 1 | 600kg/h high Quality Bakery Biscuit Making Machine in Thailand |

| 2 | 6700-00kg/h Biscuit Making Machine in South Africa |

| 3 | 700kg/h Best Price Biscuit Making Equipment In Germany Factory |

| 4 | 2t/h Automatic Cookie Making Machine in Russia |

1.What is the relationship between the choice of Biscuit Making Machine and the flour mill?

The main raw material for Biscuit Production is wheat flour and the quality of the biscuits is directly influenced by the quality of the flour. A good flour machine is the basis and backing for the development of Biscuit Making Equipment, which plays a major role in the development of Cookie Food.

Tough biscuits are generally made from wheat flour with medium gluten elasticity, good extensibility and low gluten content; shortbread biscuits are suitable for wheat flour with low gluten content; fermented biscuits are suitable for wheat flour with strong or moderate gluten elasticity, but high wet gluten content is required.

2.How do I fully emulsify the glue-like premixes in the Biscuit Manufacturing Process?

The glue-like premix is fully emulsified and the emulsion takes on an oil/water type, which is more commonly used in the Biscuit Production Process for shortbread and premium biscuits.

1.Mix the shortening, sugar, dairy products, relaxing agent, colouring and water at the same time.

2.Sometimes the Biscuit Project mixes shortening, sugar and some water to form a thick paste, then adds water and mixes to form an oil/water emulsion, in order to form a premixed paste emulsion.

3.Some can be used to inhibit gluten formation, but care needs to be taken not to over-mix in Biscuit Manufacturing Plant at high temperatures or with high protein content.

3.Why do biscuits have cracks in the Biscuit Production Process?

1.When biscuits are cooled too quickly after being removed from the oven, the heat from Biscuit Processed Products and the moisture in the air exchange and evaporate, causing additional stresses inside the biscuit and cracks to occur. The Biscuit Project is usually prone to cracking in winter when the temperature is low and dry. It is possible to cool the biscuits in the Automatic Biscuit Plant with a hood or to use temperature and humidity control equipment.

2.It is related to the amount of gluten formation, the amount of water added, the proportion of certain raw and auxiliary ingredients in the recipe, the baking temperature, the shape of the biscuit, the orientation of the pattern, its thickness, the intersection of curves and the layout of the pattern.

Milk Biscuit Production Line Vido