Our automatic biscuit making machine is summed up by a number of automatic biscuit making machine technical engineers who have more than ten years of experience. Loyal automatic biscuit making machine has a number of automatic biscuit making machine project technology patents, which can provide you with the most detailed formula and process documents, which can save biscuit manufacturing costs while improving Good development in the automatic biscuit making machine industry makes your biscuit project profitable in the biscuit manufacturing industry.

What are the raw materials of biscuits?

| Bakery Biscuits Ingredients | |

|---|---|

| Crisp Biscuits | Wheat Flour, Sugar, Oil And Fat As The Main Raw Materials, Adding Loosening Agent And Other Auxiliary Materials, The Shape Of The Powder Is Made By Cold Powder, Powder Rolling, Roller Printing Or Punching And Baking. The Structure Exhibits a Porous Structure And a Baked Food With a Loose Mouthfeel. Such As Butter Cookies, Fragrant Biscuits, Sesame Biscuits, Meringue Biscuits, Etc. |

| Tough Biscuits | Wheat Flour, Sugar, Oil And Fat As The Main Raw Materials, Adding Loosening Agent, Improver And Other Auxiliary Materials, The Shape Of The Powder By Hot Powder Process, Rolling, Roll Cutting Or Printing, Baking Is Mostly Concave Flowers, The Appearance Is Smooth, The Surface Is Flat, There Are Needle Eyes, The Cross Section Is Layered, And The Taste Is Crispy. Such As Milk Cakes, Vanilla Cakes, Egg Cakes, Mary Cakes, Boston Cakes, Etc. |

| Fermentation (Soda) Cake | Wheat Flour, Sugar, Oil And Fat As The Main Raw Material, Yeast As a Loosening Agent, Adding Various Excipients, Fermented, Fermented, Powdered, Rolled, Laminated, Baked, Crispy, With Fermented Products Specially Scented Baked Goods. The Fermented Cake, Also Known As The Chocolate Rack, Is Divided Into a Salty Fermented Cake And a Sweet Fermented Cake According To Its Formula. |

| Crispbread | A Crispy Baked Food Made From Wheat Flour, Sugar, And Fat As a Main Ingredient, Adding Seasonings And Other Auxiliary Materials, And Adjusting, Molding, And Baking. |

| Cookies | Using Wheat Flour, Sugar, And Dairy Products As The Main Raw Materials, Adding Sparse Agent And Other Auxiliary Materials, Forming a Form Of Extrusion, Extrusion, Wire Cutting, Etc. A Crispy Baked Food Having a Three-Dimensional Pattern Or a Regular Corrugated Surface And a High Fat Content. |

| Sandwich Biscuits | Sandwich-Baked Foods With Various Sandwiches Of Sugar, Grease Or Jam As The Main Raw Material Between The Two Biscuits. |

| Wafer Biscuits | Crispy Baked Goods Made From Wheat Flour (Glutinous Rice Flour) And Starch As Main Raw Materials, Adding Emulsifiers, Loosening Agents And Other Auxiliary Materials To Adjust Powder, Pouring And Baking. Also Known As Waffles. |

| Egg-Shaped Biscuits | Crispy Baked Goods Made From Wheat Flour, Sugar And Eggs As Main Raw Materials, Adding Loosening Agents, Flavors And Other Accessories, And Whipping, Mixing, Pouring And Baking, Commonly Known As Egg-Based Biscuits. |

HOW IS BISCUIT MANUFACTURED?

Regardless of whether it is a tough biscuit or a crisp biscuit, although its formula, feeding sequence and operation method are different, they all have the following basic process:

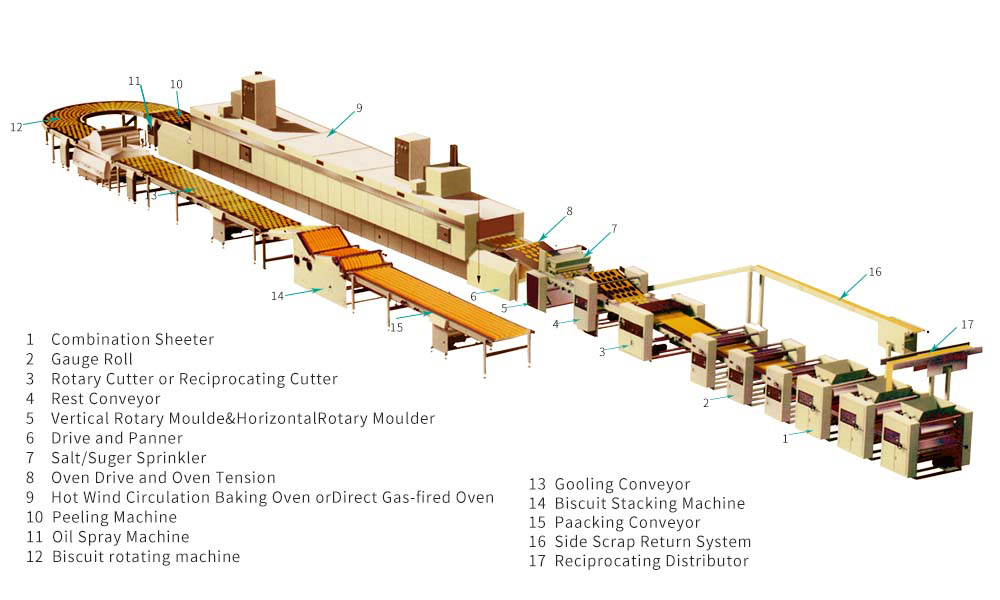

Pretreatment of raw and auxiliary materials → preparation of dough → rolling → forming → baking → cooling → finishing → packaging → finished product

Production method

Dough preparation: Dough preparation is a key process in biscuit production. The production process of crisp biscuits and tough biscuits is different, and the method of making dough is also quite different.

| Biscuit Preparation Method | |||

|---|---|---|---|

| Preparation Method | Temperature | Wet Gluten Content | |

| Crispy dough | First, pour sugar, oil, dairy products, eggs, leavening agents and other auxiliary materials and appropriate amount of water into the dough mixer and stir evenly to form an emulsion, then pour the flour and starch into the dough mixer to prepare 6~ 12 minutes or so. The essence should be added at the later stage of making into an emulsion, or added when the flour is put into it, so as to control the volatilization of the excessive aroma. | The dough temperature should be controlled at around 22-28°C. For dough with high oil content, the temperature should be controlled at 22-25°C. In summer, when the temperature is high, the dough can be prepared with ice water to reduce the temperature of the dough. | If the wet gluten content in the flour is higher than 40%, the oil and flour can be adjusted into a pastry dough, and then other accessories can be added, or part of the flour can be removed from the formula and replaced with the same amount of starch. |

| Tough Dough | Generally, Oil, Sugar, Milk, Eggs And Other Auxiliary Materials Are Heated With Water Or Hot Syrup In The Dough Mixer, And Then Mixed With Flour To Prepare The Dough. If Using a Modifier, It Should Be Added When The Dough Is Initially Formed (Both After 10 Minutes Of Preparation). Then, During The Preparation Process, The Leavening Agent And The Essence Were Added Successively, And The Preparation Was Continued. About 40 Minutes Before And After, You Can Prepare a Tough Dough. | The Temperature Of The Tough Dough Can Be Controlled At 32-35°C When The Room Temperature Is About 25°C In Winter, And 35-38°C When The Room Temperature Is 30-35°C In Summer. | The Oil And Sugar Content In The Tough Dough Ingredients Are Low, So The Gluten In The Flour Is Easy To Absorb Water And Swell, Forming a Large Amount Of Gluten. In Order To Prevent Shrinkage And Deformation, a Certain Amount Of Hot Water Can Be Added When The Dough Is Prepared To Increase The Temperature Of The Dough, So That The Gluten Can Be Fully Swollen, And At The Same Time Continue To Stir. |