As a professional Biscuits Manufacturer, our Small Biscuit Making Machines have been developed by several technical engineers with decades of experience in the biscuit making process. We can also offer you small, medium and large Industrial Biscuit Making Machines.

Our Small Scale Biscuit Making Machines have been researched and manufactured over many years in the biscuit industry and now hold a number of patents for the Small Biscuit Production Line project, and we can provide you with the most detailed biscuit recipes and Biscuit Technology process documentation free of charge when you choose to purchase a Biscuit Line.

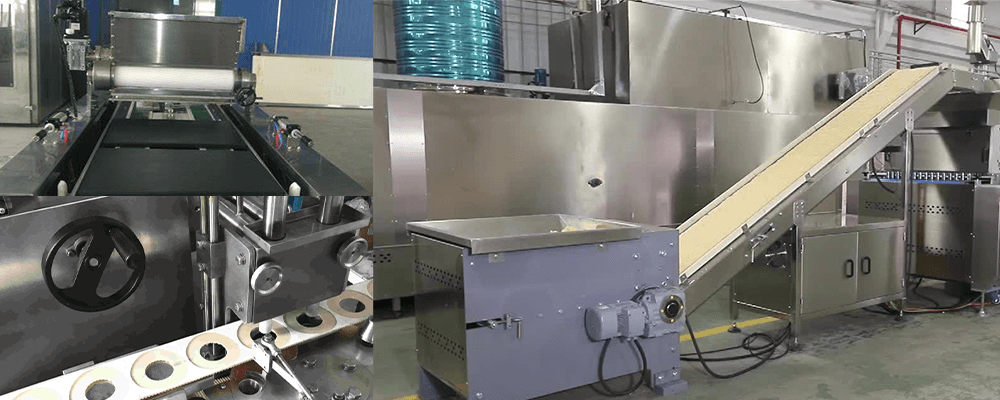

Biscuit Making Machine Diagram

What is a Biscuit Making Machine?

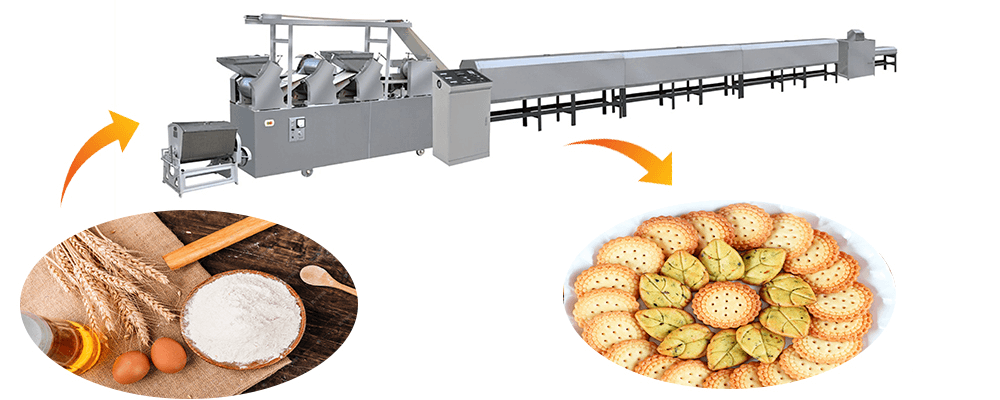

The Small Cookie Making Machine is a new type of Biscuit System that changes the traditional way of making biscuits by hand, from mixing the ingredients, to forming, to baking, we offer our customers a complete set of configurations to save their time.

Biscuit Machine diagram

Biscuit Production Line production process

Mixing → biscuit forming → biscuit cutting → controller → baking → oil spraying → cooling → packaging → finished product

Biscuit Flow Diagram

The Cookie Production Line consists of a biscuit forming machine, an electric baking oven, an oil spraying machine, a turning machine, a cooling line, a biscuit finishing machine and a packaging table. The entire Biscuit Processing Line is controlled by a CPU module, which saves space to a certain extent and is highly automated.

In addition to this Commercial Biscuit Making Machine can also produce various flavours of high quality biscuits such as cream, jam etc.

Biscuit Detail

The Small Biscuit Making Machine guarantees the quality of the machine while keeping costs under strict control, with the Small Scale Biscuit Making Machine Price being the most competitive in the Biscuit Project.

You can choose the most suitable Biscuit Manufacturing Equipment at a controlled cost and make the Biscuit Making Machine the most profitable factory item in your Biscuit Manufacturing Plant.

| Small Scale Biscuit Making Machine Price | |||||

|---|---|---|---|---|---|

| Automatic Biscuit Production Line Model | 001 | 002 | 003 | 004 | 005 |

| Biscuit Making Machine Weight (Kg) | 20000 | 28000 | 35000 | 45000 | 55000 |

| Small Scale Biscuit Making Machine Price | Us$30,000.00 | Us$40,000.00 | Us$50,000.00 | Us$60,000.00 | Us$75,000.00 |

| Biscuit Line capacity (Kgs/H) | 350-600 | 750-900 | 900-1000 | 1100-1200 | |

| Towal Power(Kw) Electric Backing Type | 300 kW | 350 kW | 500 kW | 650 kW | |

| Mixing → Biscuit Forming → Flavouring → Baking → Oiling → Cooling → Packaging | |||||

| Prices for Commercial Biscuit Making Machine are the latest promotional prices for 2022, please ask our Biscuit Processing Line team for further information. | |||||

What are the advantages of Small Biscuit Production Line?

| Advantages of Cookie Production Line | |

|---|---|

| 1 | The Automatic Biscuit Plant is made of stainless steel 304 and is easy to operate with a small footprint, low consumption, good price and high continuous productivity for even small workshops. |

| 2 | Biscuit Production Line has a wide range of models and product designs. A Biscuit Processing Line can produce crisp biscuits, hard biscuits, chocolate biscuits such as cream biscuits, sandwich biscuits, soda biscuits, animal biscuits, vegetable biscuits, etc., and the working process is long enough to allow continuous production 24 hours a day. |

| 3 | Automatic Biscuit Production Line requires fewer workers, 2-3 workers can complete the whole process from mixing the ingredients to packaging, and the operation is simple, workers can easily operate the machine after training. |

| 4 | Biscuit Making Process is free from industrial pollution and waste. |

Picture of the finished biscuit

Which Market Did The Loyal Biscuit Making Equipment Sold?

2021 Customer Order Small Biscuit Making Machine Maker Form:

| Dealed Customer Have Plant Of Small Cookie Machine | |

|---|---|

| 1 | 300kg/h Automatic Biscuit Production Line for Singapore |

| 2 | Vietnam 200-300kg/h Automatic Biscuit Plant |

| 3 | 600/h Full Automatic Industrial Biscuit Making Machine forTurkey |

| 4 | 600kg/h Professional Cookie Production Line For Sale In Sri Lanka |

| Dealed Customers Who Repurchase Of Small Scale Biscuit Making Machine At 2021 | |

|---|---|

| 1 | Japan 800kg/hhigh Quality Biscuit Making Machine Technology |

| 2 | America 300-500kg/h Easy Operation Small Biscuit Production Line |

| 3 | 700kg/h Best Price Biscuit Processing Line for Thailand customer |

| 4 | 800-1000kg/h Energy Saving Cookie Production Line in Senegal |

1.What are the ingredients used in the production of biscuits?

The main ingredient in biscuits is wheat flour, followed by a variety of other ingredients such as sugar, fats, eggs, dairy, ground peanuts, and sesame seeds.

The ingredients used vary from biscuit to biscuit, but the Biscuit Manufacturing Process is largely the same, so if you are a baking enthusiast, you can make delicious biscuits at home too.

2. Parts of the Small Scale Biscuit Making Machine

The Biscuit Making Machine is a combination of different machines that can be used individually or in combination.

1. Mixing machine: Mixes the ingredients evenly and kneads them into a smooth dough.

2. Forming machine: In this machine, the dough is rolled into shape and the biscuits are initially formed.

3. Baking oven: high-temperature baking allows the biscuits to mature, and the flavor of the biscuits is enhanced by this method of baking.

4. Oil spraying machine: A mist of oil is sprayed on the surface of the biscuit to give it a unique color and flavor.

5. Cooling machine: the biscuits can be cooled quickly so that the biscuits at room temperature do not return to moisture after packaging and have a longer shelf life.

6. Packaging machine: fully automatic packaging, from bag making to weighing, with a variety of sealing convenience, the packaged biscuits are of higher quality.

3. How to Verify Quality of Small Biscuit Production Line

1. Verify the certification of the Biscuit Making Machine, which means that the quality department has confirmed that the equipment produced by the Biscuit Making Plant meets the quality standards and that the product is acceptable as a first requirement.

2. Acceptance of the Industrial Biscuit Making Machine in accordance with the technical agreement, whether it meets the actual requirements and whether it meets the intended requirements, etc.

3. Acceptance of the equipment in accordance with the Biscuit Production Line management standards, including the integrity of the components and cleanliness of the equipment, and the development of a maintenance plan for the equipment.