Designed by engineers with many years of experience in cookie making technology, the energy efficient and highly effective Fully Automatic Biscuit Production Line was created.

The Biscuit Production Line consists of a biscuit forming machine, a tunnel type hot air circulation electric baking oven, a greasing machine, a bending machine, a cooling machine, a biscuit finishing machine and a sandwich packing machine.

The whole line is controlled by a CPU module and driven by a back mounted motor. The Automatic Biscuit Machine is compact and highly automated.

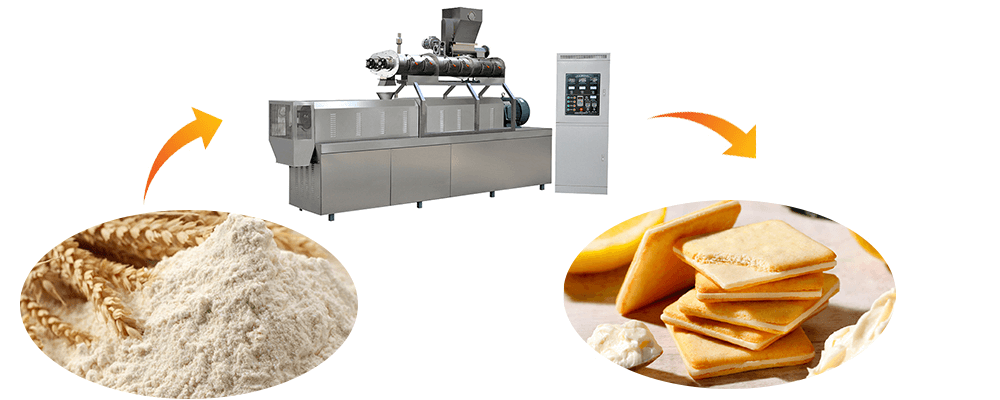

Biscuit Machine Diagram

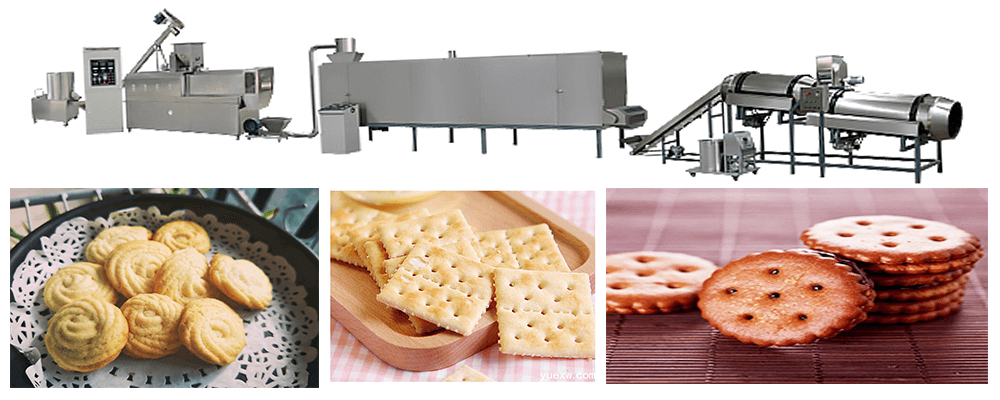

What types of biscuits are there?

Types Of Cookies can be divided into two categories: tough biscuits and shortbread biscuits, both are made of wheat flour, sugar and fat as the main raw materials, plus other auxiliary ingredients, through the blending, rolling, rolling and baking Biscuit Project baked goods, a variety of shapes, rich taste, including cream biscuits, sesame biscuits, vanilla biscuits, etc.

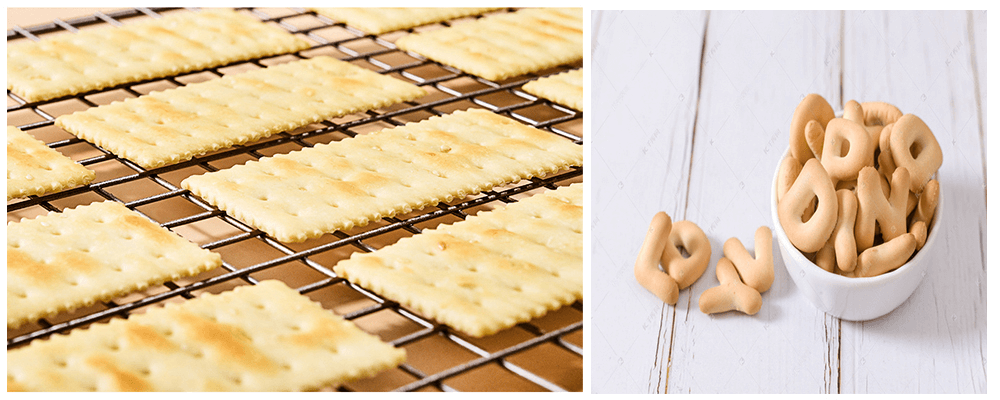

Biscuit picture

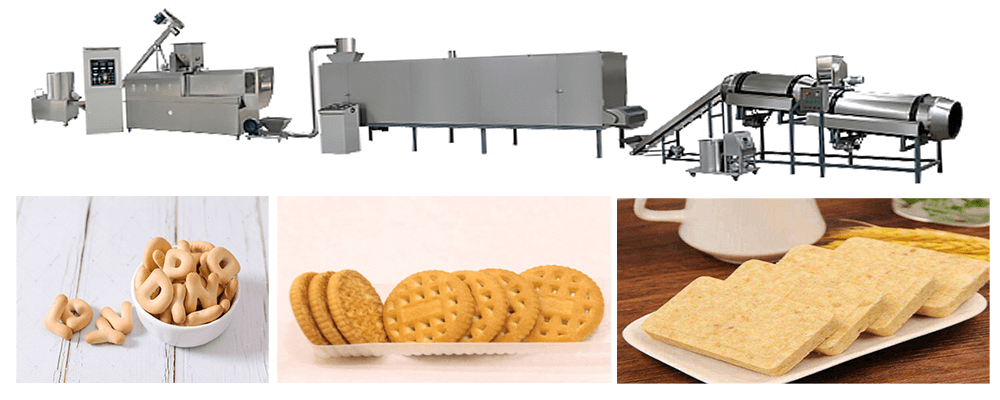

What are the advantages of the Automatic Biscuit Making Machine?

1.Bakery Biscuit Machine> has a simple, compact and precise structure, eliminating the need for residual material transport. The Cookie Maker uses imported electrical components and can be frequency-controlled, energy-saving, single and joint-controlled.

2.Automatic Biscuit Production Line works continuously and smoothly, with low impact and vibration noise, high production capacity and good quality of Finished Biscuit.

3. Biscuit Manufacturing Equipment has automatic constant temperature and baking functions, energy saving and power saving, easy to operate by staff, lower cost of use and better cost performance.

Biscuit machine diagram

How to control the formation of gluten in the Biscuit Making Process?

| Biscuit Manufacturing Process points to note for gluten | ||

|---|---|---|

| 1 | Dosing sequence | The Biscuit Manufacturing Process requires the mixing of auxiliary ingredients other than wheat flour into a glue paste, i.e. the premixing of the auxiliary ingredients. At the same time, ingredients such as dairy flour and flour, which tend to clump together, are sieved. |

| 2 | Sugar and oil | Some dough are easier to control when there is too much sugar and oil, and more likely to rise when there is less. Be careful to avoid over-mixing. |

| 3 | The amount of water added and the softness of the dough | Dough with more water are more prone to gluten formation and require shorter mixing times, while dough with less water need longer mixing times. |

| 4 | Adding starch and the amount of head seeds | The amount of starch and seeds added to the dough should be controlled, generally 1/10-1/8, to avoid excessive gluten formation. |

| 5 | Mixing time and resting time | Under-flouring and over-flouring can cause the dough to shrink, so the flouring time for the Biscuit Making Process depends on how well the dough is kneaded. If the gluten formation is insufficient, this can be remedied by resting the dough properly to increase its elasticity. |

Biscuit machine diagram

Industrial Biscuit Making Machine equipment parameters :

| Equipment models | Output | Total voltage | Air consumption | Supply voltage | Weight |

|---|---|---|---|---|---|

| 225 | 1T/Day | 40KW | 15m³/h | 400V | 1600kg |

| 600 | 6T/Day | 120KW | 40m³/h | 400V | 3000kg |

| 1000 | 10T/Day | 190KW | 80m³/h | 400V | 5000kg |

| Mixing machine → Forming machine → Baking oven → Oil spraying machine → Cooling machine | |||||

Machine details

Our Automatic Biscuit Making Machine has been well received by our customers for its reliable equipment and advanced Cookie Maker Technology.

The Biscuit Manufacturing Equipment market is expanding indefinitely, with sales in countries all over the world. The Biscuit Manufacturing Equipment market is expanding indefinitely.

| 2021 Butter Biscuit Making Machine Customer Case Study | |

|---|---|

| 1 | Bakery Biscuit Machine for sale in Indonesia with 800kg/h high quality |

| 2 | 800-900kg/h Biscuit Making Equipment for sale in France |

| 3 | 1t/h Cookie Making Machine for sale in Singapore |

| 4 | 800kg/h Small Cookie Making Machine for sale in Germany |

| 5 | 700kg/h Small Biscuit Making Machine for sale in Thailand |

| Example of a customer who bought back an Automatic Biscuit Making Machine in 2021 | |

|---|---|

| 1 | 700-800kg/h Cost-effective Industrial Biscuit Making Machine for sale in South Africa |

| 2 | 600kg/h Commercial Biscuit Making Machine for sale in Russia |

| 3 | 1t/h energy efficient Automatic Biscuit Making Machine for sale in Japan |

If you are also interested in Biscuit Manufacturing Plant, please feel free to contact us to ask questions about Automatic Biscuit Production Line.

We will also advise you on Biscuit Manufacturing Units business issues based on our Biscuit System expertise.

1. What should I look for in the wet gluten content of different Biscuit Projects?

1. Shortbread biscuits.

The choice of wheat flour in the Biscuit Making Process needs to be a soft wheat processed weak flour with a wet gluten content of 19% to 22%, if the gluten is too strong it can be adjusted with starch.

2. Tough biscuits.

The wheat flour used for Biscuit Processing should have good gluten elasticity, elongation and a low gluten content, with a wet gluten content of 21% to 28%.

Be aware that a low gluten content can lead to cracked and broken biscuits.

3. Fermented biscuits.

Biscuits are generally fermented using the secondary fermentation method Biscuits Production Technology.

Therefore, the first and second fermentation are different.

To prevent the dough from becoming too elastic, a wheat flour with a high gluten content of around 30% wet gluten should be used for the first time.

For the second fermentation, use a less glutenous wheat flour with a wet gluten content of 4% to 26%.

4. Wafer biscuits.

Biscuits Processing generally uses wheat flours with a wet gluten content of around 23%.

It is important to note that if the gluten content is too high, the Biscuit Production will come out dry and hard and not crispy.

If it is too low, the biscuit will break easily.

It is therefore important to keep the wet gluten content to a minimum, not too high and not too low.

2. What are the characteristics of the Biscuit Sorting Machine?

1. The Biscuit Finishing Machine is equipped with an advanced frequency converter.

The Biscuit Finishing Machine is equipped with a state-of-the-art frequency converter, which allows for infinitely variable speed control and joint speed control, making the Biscuit Production Line run more smoothly and reliably and with greater safety.

2. The Cookie Finishing Equipment has a star wheel to organize the finished biscuit products in an orderly manner.

The machine is also capable of double-row conveying for high production efficiency and output.

The Automatic Biscuit Production Line is an automated machine with an automatic thermostat system.

The Automatic Biscuit Production Line is an automated machine with an automatic thermostat system, which automatically controls the temperature and ensures a constant temperature for the sandwich filling, ensuring the safety and taste of the Biscuit Food.

4. The Cookie Finishing Machine is made of stainless steel, which makes it more robust and reliable.

The shape of the machine is also new.

3. How is the performance of the Biscuit Forming Machine?

There are two types of Biscuit Forming Machine, the Stamped Biscuit Forming Machine and the Roll Forming Biscuit Forming Machine, which have different operating principles.

Stamping Biscuit Forming Machine: There are two types of machine: intermittent and continuous.

The intermittent machine has a lower speed and lower production capacity, and is prone to large shocks and vibrations, which can cause uneven thicknesses and edge breakage.

The continuous mechanism is smoother and has a higher capacity.

The Biscuit Blank is the choice of the Automatic Biscuit Processing Line because of its better forming quality.

This Biscuit Processor is completed by one rotation of the roller that performs molding and demolding.The Biscuit Processing Machine is a smooth turning machine with no impact, noise or edge residue.

The Biscuit Processing Machine rotates smoothly, without impact, noise or edge residues. It is also easier and more reliable to operate and less costly. It is commonly used for the production of high fat biscuits.