Loyal is a Biscuit Making Equipment manufacturer specializing in Biscuit production technology and has over 10 years experience in Biscuit Technology in the Biscuit Project.

The Loyal Small Biscuit Making Machine has an excellent Biscuit Manufacturing Process in terms of craftsmanship.

Thanks to the continuous efforts and innovations of our engineers, the entire Biscuit Processing Line has been set up in accordance with the food machinery standard system, making it easier for Biscuit Manufacturing Units to produce food-approved biscuits.

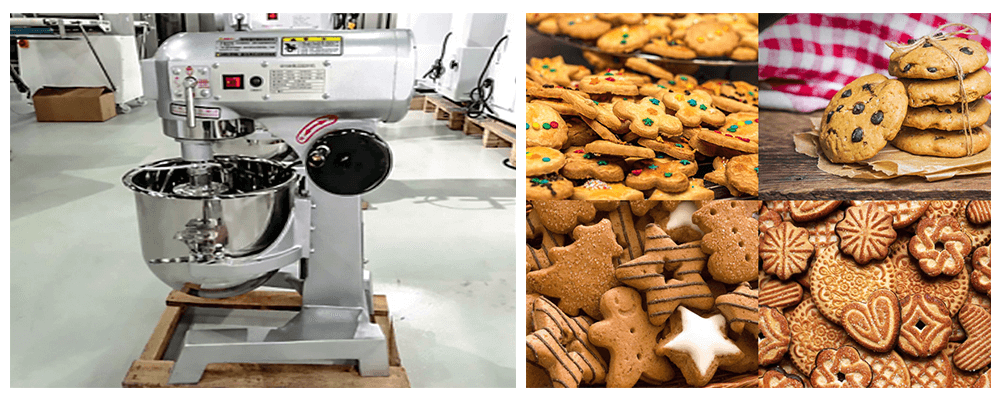

Biscuit Machinery Diagram

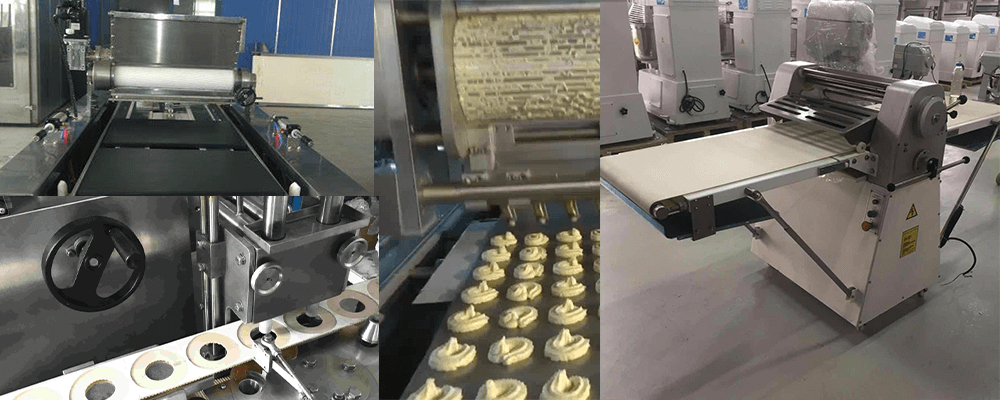

Biscuit Manufacturing Equipment process flow: flour, auxiliary materials -> dough modulation -> pressing -> roll cutting and forming -> baking -> oil spraying -> cooling -> finished product

Commercial Biscuit Making Machine adopts CPU module control, back hung motor drive, compact structure, high degree of automation, from feeding, three pressed dough, forming, sifting sugar, conveying, waste, recycling. Baking, oil spraying and cooling are all done automatically with electromechanical integration.

Biscuit Machinery detail picture

What are the types of biscuits?

The main raw material for biscuits is wheat flour with the addition of sugar, fats, eggs, dairy and other auxiliary ingredients.

The Cookie Production Line can produce different types of biscuits depending on the recipe and production process, with the biscuits being divided into two categories: tough biscuits and shortbread biscuits.

| Types of biscuits | Soft biscuits, hard biscuits, butter biscuits, sandwich biscuits, soda biscuits, animal biscuits, vegetable biscuits, cream biscuits, ultra-thin biscuits, soda biscuits, animal biscuits, etc. |

What makes biscuits popular?

Biscuits are made from cereal flours (and/or pulses, potato flours), etc., with a variety of supplementary seasonings through the Biscuit Production Line process of flouring, forming, and baking. They can also be made by adding cream, egg white, cocoa, or chocolate to the surface or inside of the biscuit and are a common snack today.

Biscuits have always been a popular afternoon tea because of the variety of biscuits available to meet the needs of different audiences.

Biscuit picture

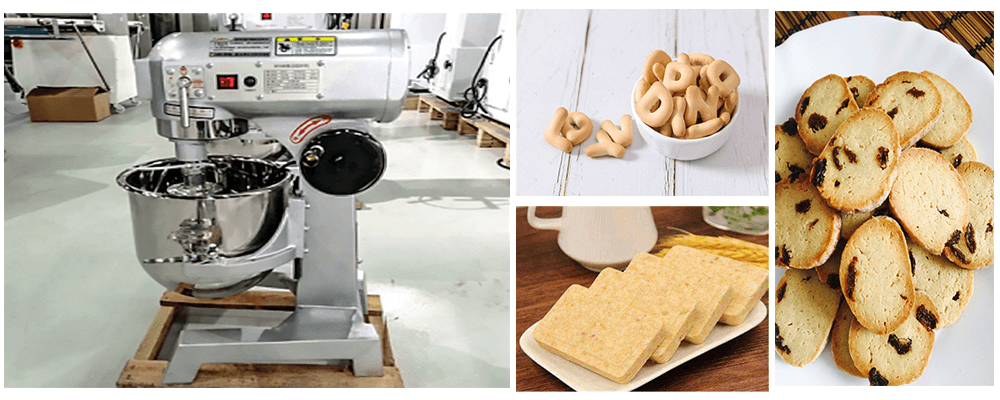

Why choose Automatic Biscuit Production Line?

| Advantages of Bakery Biscuit Making Machine |

|---|

| 1. The Biscuit Making Machine is of the highest quality, easy to operate and highly productive. |

| 2. The Small Biscuit Making Machine PLC and touch screen provide the latest technology for programming all controls and operations. |

| 3. The Industrial Biscuit Making Machine is highly automated and requires only 2-3 workers to run the entire Biscuit Making Machine For Factory. |

| 4. Small Cookie Making Machine is highly efficient and can be used for more profit, saving manpower and extending the life of the machine. |

| 5. A wide range of biscuits can be processed and produced, with high productivity and a wide range of applications. |

Biscuit making machine diagram

2021 Bakery Biscuit Making Machine customer success stories

Loyal has a wide scope for continued growth in the biscuit industry thanks to its high quality equipment and comprehensive service system. To date the Biscuit Processing Line has been widely recognized by customers both at home and abroad and is well liked by Biscuit Making Plant.

| Customer cases of Automatic Biscuit Making Machine in 2021 | |

|---|---|

| 1 | 300KG/H Automatic Biscuit Making Machine from Pakistan |

| 2 | 200-500KG/H Biscuit Production Line for a customer in Thailand |

| 3 | 300kg/h Biscuit Making Machine for sale in Ukraine |

| 4 | 500KG/H Industrial Biscuit Making Machine and Biscuit Manufacturing Process in Mozambique |

| 5 | 1000Kg/H High Quality Commercial Biscuit Making Machine for sale in Senegal |

| 2021 Sold to customer Biscuit Manufacturing Process | |

|---|---|

| 1 | 200kg/H Small Biscuit Manufacturing Equipment for sale in Vietnam |

| 2 | 300kg/H Biscuit Manufacturing Process for sale in Nigeria |

| 3 | 500kg/h Biscuit Making Plant for sale in Bangladesh |

Biscuit picture

If you would like to start a Biscuit Project business, feel free to contact us to enquire about the Biscuit Making Machine. We ensure that the Biscuit Making Machine Price is the most competitive in the biscuit market by keeping a tight rein on costs while ensuring superior quality. Biscuit diagram

Frequently asked questions about the Industrial Biscuit Making Machine

1. Do I need to clean the Bakery Biscuit Making Machine regularly?

1. The Automatic Biscuit Making Machine requires frequent cleaning of the machine. Take the filter out regularly and clean it. Of course, during the cleaning process it is important to wait until the machine has cooled down completely before you start cleaning. After repeated cleaning, rinse the filter screen of any impurities. Use a brush to gently scrub the filter if necessary.

2, after cleaning the filter should be put back into the machine in time, and pay attention to the correct location to avoid causing safety hazards.

3、Of course, when cleaning, attention should be paid to the removal of debris and the collection of impurities, and the site must be cleaned up after the operation.

4. If the mixing blades in the Biscuit Processing Line are not easy to clean, they must be cleaned several times. Of course, do not use abrasive cleaners and hard woolen fabrics to avoid damaging the non-stick layer and affecting the normal use of the machine.

2. How do I install and control the Biscuit Processing Line after I have purchased it?

Loyal does not only focus on the quality of the Biscuit Line, but also on the after-sales service. Not only do we offer the Biscuit Manufacturing Process, but we can also customise the Cookie Making Machine to suit your needs.

Our technicians will help you with the installation and control in the shortest possible time, and you can ask us any questions you may have during the Biscuit Making Process.