Loyal Biscuit Machine has more than ten years of experience in the Biscuit Manufacturing Process. The Bakery Biscuit Machine is a Biscuit Equipment with automatic electromechanical integration from feeding, triple pressing, forming, sifting, conveying, scrap, recycling, baking, spraying, cooling, etc.

Commercial Biscuit Making Machine is a professional food machine used to produce all kinds of cookies. It is high-quality Biscuit Making Equipment obtained by Loyal Biscuit Manufacturing Units engineers after continuously absorbing advanced technology at home and abroad and innovating.

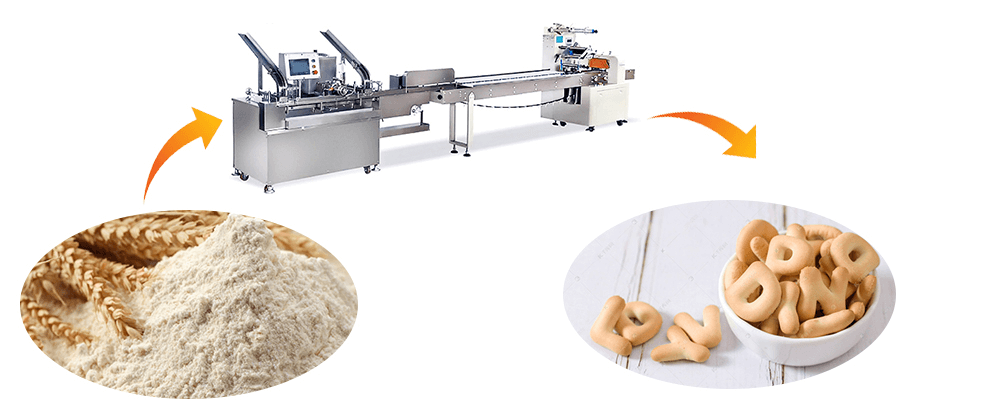

Biscuit Making Machine Diagram

What are the steps of Bakery Biscuit Making Machine?

| Steps of Biscuit Making Machine For Factory | |

|---|---|

| Raw material processing | Sifting of flour, crushed sugar, brown oil, shortening, milk powder, baking soda, sesame seeds, edible flavoring, edible salt, etc. |

| Dough mixing | Putting the ingredients into the equipment and forming the dough through the mixer of Biscuit Production Line. |

| Roll cutting and forming | The dough is pressed into sheets and then rolled and cut into biscuits. |

| Baking | The shaped biscuits go directly into the baking oven where they are heated directly to ripen. |

| Oil spraying | The matured pie cone is sprayed with brown or canola oil at about 40°C on its surface. |

| Cooling | After oiling, the cookies are cooled naturally on the cooling line until the moisture level is below 3%. |

| Packaging | After cooling, the cookies are packed in OPP and CPP bags or aluminum bags, and then packed in cartons. |

The process flow of Automatic Bakery Biscuit Machine is.

Flour machine-Biscuit forming machine-Import oven-Tunnel type hot air circulation oven-Export oven-Biscuit stripping machine-Oil spraying-Cooling section line-180° turning machine-Cooling line-Biscuit stacking machine-Sorting table-Packing machine

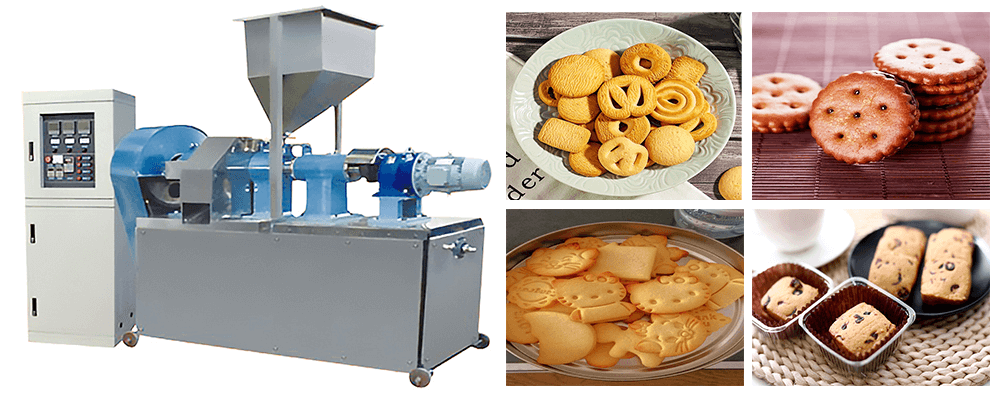

Cookie machine detail picture

Loyal Biscuits Manufacturer’s Biscuit Making Machine has borrowed from the most advanced foreign Biscuit Making Plant development experience and listened to the actual use of many customers’ feedback suggestions; now Biscuit Project has become the hot Automatic Biscuit Making Machine.

| Advantages of the Automatic Biscuit Production Line | |

|---|---|

| Increased production | Biscuit System has a highly automated production method and can work continuously for 24h. The production efficiency is very high and the capacity per unit time is higher, which allows the manufacturer to cope with more orders, thus expanding the market scale and increasing profits. |

| High product quality | Biscuit Making Plant’s mechanized production method does not require human intervention, which ensures the stability of production and a very high production standard at every step. |

| Reduced labor | Biscuit Manufacturing Equipment has a PLC control system that is easy to operate. The highly automated production method can effectively reduce labor, and the entire candy production line only requires 1-2 people to complete production, which greatly reduces labor requirements and labor costs, thus ensuring food quality and reducing production costs. |

| Ensure food safety | The Cookie Production Line is made of food-grade stainless steel, and the entire Biscuit Making Process is clean and hygienic with high quality standards, providing consumers with greater peace of mind. |

Over the years, Loyal Biscuits Manufacturer has very rich research and development achievements. The Cookie Production Line research and development production has received CE, ISO9001, and many other certifications and has attracted a considerable number of Biscuit Manufacturing Units.

Biscuit Machine Diagram

| Cases of Biscuit Making Equipment customers that have been sold in 2021 | |

|---|---|

| 1 | 1 Sale of 500kg/H Biscuit Making Plant in South Africa |

| 2 | Sale of 800kg/H Biscuit Manufacturing Equipment in India |

| 3 | 300kg/H Automatic Biscuit Making Machine sold in Pakistan |

| 4 | 500kg/H Industrial Biscuit Making Machine for sale in Mozambique |

| 5 | 1Tkg/H Bakery Biscuit Making Machine for sale in Pakistan |

Biscuit Diagram

For more questions about our Biscuit Processing Line and services, you can always contact us, and our experienced Biscuit Manufacturing Process service team will be sure to give you a satisfactory answer in the shortest possible time.

1. How do you set up an Automatic Biscuit Plant project?

A small Automatic Biscuit Plant is a lucrative food business.

You need to produce soft and hard cookies, sandwich cookies, and cookies according to the local market demand by choosing the right recipe from dozens of recipes provided by Loyal for free.

2. Loyal about Industrial Biscuit Making Machine after-sales service

We provide you with professional Biscuit Manufacturing Process engineers to guide you through the process of various famous cookie brands.

We provide you with the most detailed cookie recipes and cookie manufacturing process for free to save your cookie workshop production cost, and at the same time, better develop the Biscuit Manufacturing industry and make your Biscuit Project profitable.

As the standard of living continues to provide, the demand for snacks is also increasing, so the profit margin of cookie production can reach at least 30%. For large-scale commercial production of cookies, profits can be as high as 50%.