Our biscuit making machine for factory is summed up by a number of biscuit making technical engineers who have more than ten years of experience. Loyal has a number of biscuit making project technology patents, which can provide you with the most detailed formula and process documents, which can save cost of biscuit making machine while improving good development in the biscuit manufacturing industry makes your biscuit project profitable in the biscuit manufacturing industry. The raw material of biscuit equipment is stainless, and the products produced with good tasty, etc.

Brief Introduction Of Biscuit Manufacturing Machine

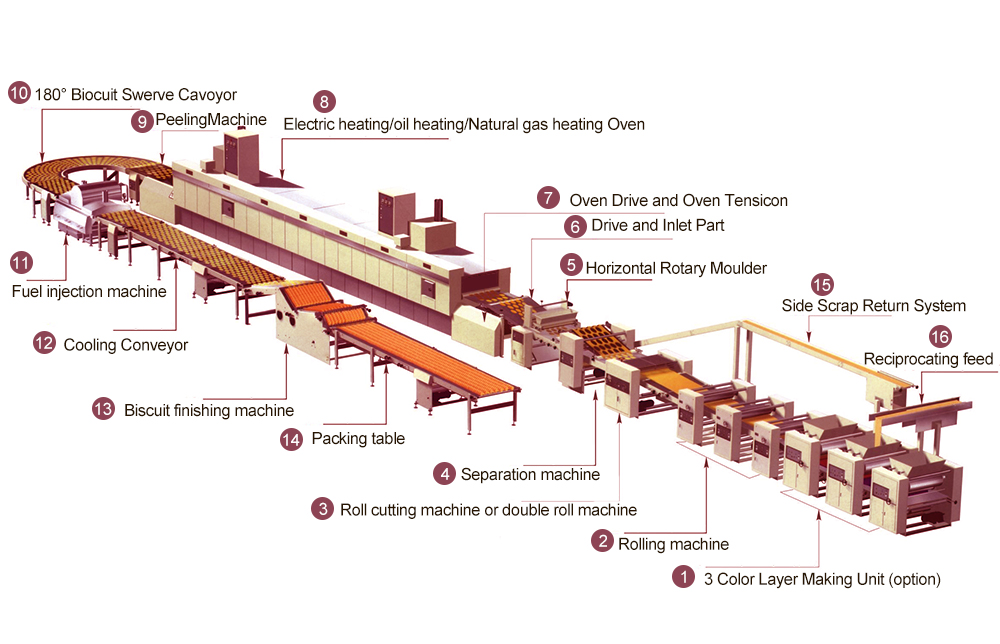

The biscuit production line is composed of biscuit forming machine, tunnel type hot air circulation electric oven, oil injection machine, turning machine, cooling line, biscuit sorting machine, biscuit sandwich machine, packaging table, etc. The whole line is controlled by CPU module, driven by a back-mounted motor, with a compact structure and a high degree of automation. All mechatronics such as baking, oil injection and cooling are automatically completed.

What Is Biscuit Manufacturing Machine Price

| Biscuit manufacturing machine | |||||

|---|---|---|---|---|---|

| Model | 225 | 280 | 400 | 600 | 1000 |

| Total installed capacity (kw) | 28.5 | 56 | 120 | 200 | 300 |

| Baking temperature(℃) | 200-300 | 200-300 | 200-300 | 200-300 | 200-300 |

| Production capacity (kg/h) | 50 | 100 | 200 | 300 | 1000 |

| Dimensions (l×w×h)(mm) | 18000×600×1500 | 28000×800×1500 | 48000×1000×1500 | 76000×1200×1750 | 103000×1850×2450 |

| Price(USD) | 16000 | 20000 | 22000 | 26000 | 30000 |

| The biscuit manufacturing machine price is a promotional price in 2022, update price. Check with our biscuit manufacturing machine team. small biscuit making machine price | |||||

What Are The Ingredients Used In Making Biscuits?

The main raw material of biscuits is wheat flour, and then add sugar, oil, eggs, dairy and other auxiliary materials.

| Biscuit manufacturing machine | |

|---|---|

| Soft biscuits | With wheat flour, sugar and oil as the main raw materials, adding bulking agents and other auxiliary materials, the shapes made by the cold powder process of powder mixing, rolling, rolling printing or punching and baking are mostly convex, with a cross-sectional structure. Baked food with porous structure and loose taste. Such as cream biscuits, scallion biscuits, sesame biscuits, meringue biscuits, etc. |

| Hard biscuits | Take wheat flour, sugar and oil as the main raw materials, add bulking agents, improvers and other auxiliary materials, and the graphics made by hot powder process, rolling, roll cutting or printing and baking are mostly concave flowers. Smooth, flat surface, with pinholes, layered cross-section, and crispy baked goods. Such as milk cake, vanilla cake, egg cake, mary cake, boston cake and so on. |

| Fermented (soda) biscuit | With wheat flour, sugar and oil as the main raw materials, yeast as a bulking agent, adding various auxiliary materials, after fermentation, powder mixing, rolling, lamination and baking, it is crunchy and has the unique characteristics of fermented products. Fragrant baked goods. Fermented cakes, also known as chocolate racks, are divided into salty fermented cakes and sweet fermented cakes according to their recipes. |

| Crispy biscuits | A crispy baked food made of wheat flour, sugar and oil as the main raw materials, adding condiments and other auxiliary materials, after mixing, molding and baking. |

| Cookies | Using wheat flour, sugar, and dairy products as the main raw materials, adding sparse agent and other auxiliary materials, kneading the noodles, forming one of the methods of extrusion, extrusion, wire cutting, etc., and baking. Crisp baked goods with three-dimensional patterns or regular ripples on the surface and high oil content. |

| Sandwich biscuits | Sandwich baked goods with various sandwich materials added between two biscuits with sugar, oil or jam as the main raw material. |

Oat Biscuit Recipes

| Fully automatic biscuit making machine | |

|---|---|

| Oatmeal 20% | Low-gluten flour 24% |

| Raisins 15% | Cinnamon Powder 5% |

| Milk 10% | Egg 10% |

| Rum 5% | Lemon Juice 2% |

| Butter 4% | Sugar 3% |

| Baking powder 1% | salt 1% |

How do you make biscuits?

| Technology for biscuit manufacturing machine | |

|---|---|

| Pre-treatment of raw and auxiliary materials | Instructions–flour sieving, sugar crushing, palm oil, shortening, milk powder, ammonium bicarbonate, baking soda, enzyme preparation, sesame, sodium metabisulfite, edible flavor, edible salt |

| Kneading | Instructions–Put the raw and auxiliary materials into the mixer and mix them into dough. Adopt equipment–600 type horizontal mixer. Mixing time 15-25 minutes. |

| Rolling and cutting into shape | Instructions–After pressing the dough into four sheets, roll it and cut it into cake shells. Sprinkle sesame or peanuts or sugar or salt or not before putting it into the oven. |

| Baking | Instructions – The formed cake embryo enters the oven and is heated by an electric heating tube to make the cake embryo mature. Use a Model 1000 direct-fired gas oven. Use temperature–230-270℃ Baking time–4~5 minutes |

| Oil spraying | Instructions–The surface of the baked biscuits is sprayed with palm oil or rapeseed oil at about 40°C. |

| Cooling | Description–The oil-sprayed biscuits need to be naturally cooled by the cooling line until the moisture is below 3%, and the biscuit temperature is about 30 ℃. |

| Packaging | Instructions–After cooling, the biscuits are packed in OPP and CPP composite bags or aluminum thin packaging bags, and then packed in cartons. |

| Finished product | Description–The finished product that has passed the packaging inspection must be stored at room temperature below 25°C and relative humidity below 60%. |

What are the 4 types of biscuits?

There are hard biscuit, soft biscuit, sandwich biscuit and cookies are popular in the market. According to different recipes and production processes, sweet biscuits can be divided into two categories: hard biscuits and soft biscuits.

The characteristics of hard biscuits are that the impressions are mostly concave and there are pinholes on the surface. The surface of the product is smooth and smooth, the cross-sectional structure is layered, and it has a crunchy feeling when chewed, chewy, and crunchy for its unique characteristics. hard biscuits have a lower sugar-to-fat ratio than soft biscuits.

Generally, the amount of sugar is less than 30%, and the amount of oil is less than 20%. The characteristics of crisp biscuits are that the impressions are mostly convex, with obvious patterns and fine structures, which are 14% to 30% of the flour content. For some special products with loose sweetness, the amount of oil and fat can be as high as 50%.

Sandwich biscuits are based on hard biscuits or soft biscuits sandwiched with a layer of cream to enrich the taste of hard biscuits or soft biscuits. It is a diversified choice for customers and meets the taste buds of different customers.

Cookies are different from the first three types of cookies. Compared with soft cookies or hard cookies, the equipment used is different. The cookie forming machine is a line cut or drop type, with beautiful shape and soft taste.

What type of flour is used to make biscuits?

| Biscuit making machine for factory | |

|---|---|

| There are two types of biscuit flour, one is high-gluten flour, and the other is low-gluten flour. The specific choice depends on the biscuits made. The specific choices are as follows | |

| 1hard biscuit | This type of biscuit is made of high-gluten flour. From the name, it can be seen that the shape of the biscuit is very thin. Because it is thin, high-gluten flour is used, because the high gluten content of high-gluten flour can effectively support crackers. Qualitative; |

| 2soft biscuit | These biscuits are made from low-gluten flour, which is famous for its crisp, crisp and fragrant products. The ingredients for this type of biscuits are generally low-gluten flour. |

Customer cases for biscuit making machine for factory in 2021

Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company’s products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the biscuit making machine, please contact LOYAL immediately, we will provide you with high-quality formulations of biscuits, hard biscuit and other products, professional technical process guidance, and a full range of professional market analysis.

| Customer cases forbiscuit making machine for factory in 2021 | |

|---|---|

| 1 | 1t/h cost of biscuit making machine sold in russia |

| 2 | 1t/h biscuit making machine for factory for sale in puerto rico |

| 3 | 1t/h small biscuit making machine price for sale in bolivia |

| 4 | Senegal 1t/h industrial fully automatic biscuit making machine |

| 5 | 1t/h biscuit manufacturing machine for sale in côte d’ivoire |

| 6 | China 300t/year industrial fully automatic biscuit making machine |

| Customer case of biscuit manufacturing machine at 2021 | |

| 7 | 1t/h biscuit making machine for factory in uzbekistan |

| 8 | 1000kg/h industrial biscuit manufacturing machine for sale in senegal |

| 9 | Mozambique 1t/h fully automatic biscuit making machine |

| 10 | Bangladesh 2t/h fully automatic biscuit making machine |

| Dealed customer have technology of biscuit manufacturing machine at 2021 | |

| 11 | 1t/h thai biscuit making machine for factory |

| 12 | Uzbekistan 1t/h fully automatic biscuit making machine |

| 13 | Usa 1t/h biscuit manufacturing machine |

| 14 | 800kg/h industrial small biscuit making machine price for sale in nigeria |