After years of Biscuit Machining and Manufacturing Technology, we have worked with engineers who have decades of experience in Biscuit Machine Manufacturing to upgrade Biscuit Manufacturing Units. We have launched the new Fully Automatic Biscuit Machine, which comes with design instructions, recipes, and molds for customers to choose the right cookie maker. The Biscuit Machine will be more convenient to operate.

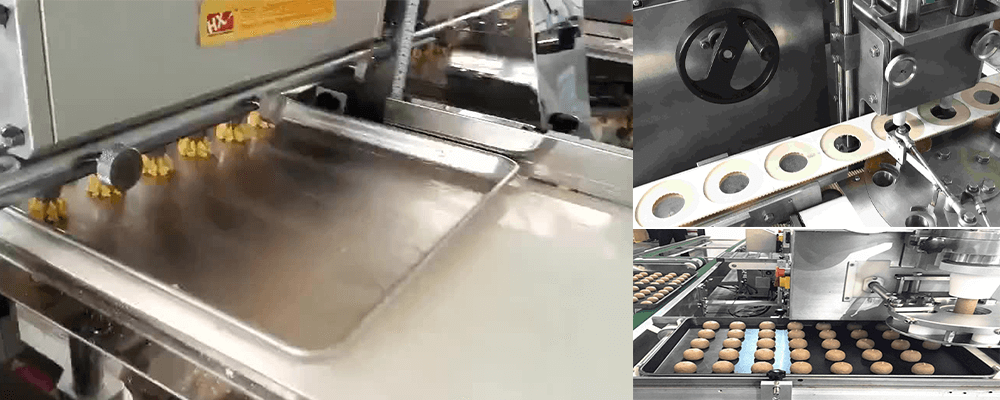

Biscuit Machine Diagram

What is the leading equipment included in the Biscuit Processing Line?

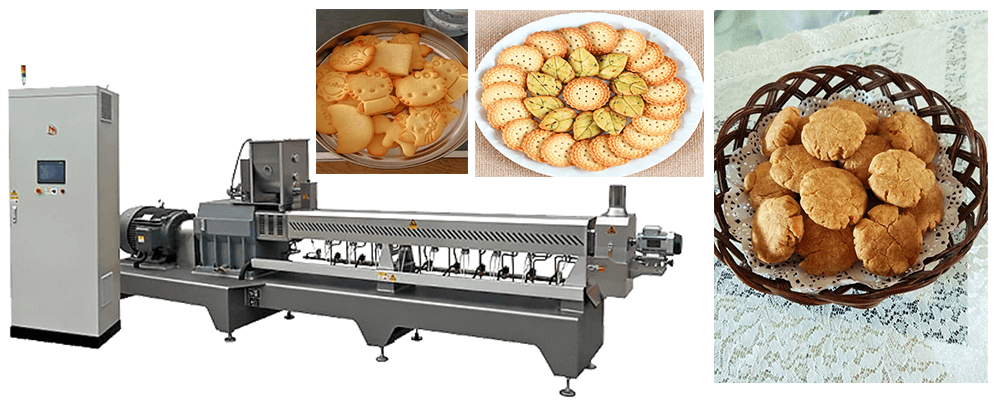

The Biscuit Making Machine can be used to produce crisp cookies, tough cookies, soda cookies, and sandwich cookies. It can also be used to make cookies in the shape of Cookie Brand by using different molds to create the exclusive Biscuit Enterprise logo.

Cookie diagram

Process flow of Automatic Biscuit Production Line.

Dough mixing → roll cutting/roll printing → electric/gas heating → oil spraying → cooling → finishing → sandwiching → packaging.

What are the advantages of Biscuit Processing Line?

| 1 | Biscuit Making Equipment has a novel design to meet the output of various cookie products with compact and precise structure. |

| 2 | The Cookie Production Line is highly automated and has a human-machine interface, which is easy for staff to operate. |

| 3 | Automatic Biscuit Production Line has automatic temperature adjustment system, which is easy to control the temperature and humidity inside the cranium, and the Biscuit machine equipment has electric heating indication function, which is a full-function baking oven made of high quality electrical components. |

| 4 | Biscuit Making Process has electromagnetic speed control, which is more safe and reliable, and also can keep the cookies neatly arranged, which is convenient for Biscuit Project installation. |

| 5 | Bakery Biscuit Making Machine has perfect function, stable operation, high cost performance and low maintenance cost. |

Biscuit Machine details

Basic processing ingredients for Automatic Biscuit Production Line:

| 1 | Wheat flour | Low gluten flour with low ash content and a coarseness pass through a 150 μm mesh sieve is required. |

| Tough cookie | Biscuit Making is suitable for wheat flour with medium gluten elasticity, good extensibility, and low gluten content, with wet gluten content between 21% and 28%. | |

| Shortbread Biscuit | Biscuit processing should use soft wheat flour with 19% to 22% wet gluten content. | |

| Fermented cookies | For the first fermentation, use wheat flour with solid gluten and wet gluten content of about 30%; for the second fermentation, use wheat flour with slightly weaker gluten and damp gluten content of 4% to 26%. | |

| 2 | Starch | It is used to dilute the concentration of gluten and reduce the gluten of dough. Commonly used starches are wheat, corn, and potato starch. |

| 3 | Grease | Biscuit Manufacturing Process should use fats with excellent crispness and high stability. |

| Tough cookie | The amount of grease used is less, and cream, margarine, refined lard, etc., are generally used. | |

| Crisp cookie | The number of fats and oils used is more significant. The factors to be considered are shortening, good stability, and high melting point fats; usually, margarine and vegetable shortening are used. | |

| Fermented cookies | Both stability and crispness are required, with higher requirements for shortening. Refined lard and vegetable shortening are usually used. | |

| 4 | Yeast | is an important factor affecting the Biscuit Manufacturing Process and therefore has to perform well. |

| 5 | Phospholipid | is an edible natural emulsifier, the proportioning amount is usually 5%~15% of the amount of fat. |

| 6 | Loosening agent | Tough cookies, in general, use mixed relaxants, the proportion of 1% of the amount of powder. |

| 7 | Flavorings | Types of dairy products and salt are two types to improve the taste and enhance nutritional value. |

| 8 | Flavors | Generally following the number of food additives requirements, Biscuit Processing Technology uses heat-resistant essential oils, such as banana, orange, pala, and coconut essential oils. |

| 9 | Other additives | Including tert-butyl p-hydroxyanisole (BHA), 2.6 a di-tert-butyl p-cresol (BHT), propyl gallate (PG), etc., the amount should not exceed 0.01% of the amount of oil and grease. |

Biscuit Machine Diagram

Case of Commercial Biscuit Making Machine ordered by customer in 2021:

We aim to provide our customers with high standard and quality Biscuit Making Equipment. At the same time, we aim to provide our customers with good after-sales service and application instructions. We have established a wide range of contacts with customers both at home and abroad, and the market for Biscuit Production Line for sale overseas is expanding.

| Examples of customers of Automatic Biscuit Making Machine | |

|---|---|

| 1 | Canada 300kg/h Automatic Electric Industrial Biscuit Making Machine for sale |

| 2 | India 700-800kg/h Cookie Making Machine for sale |

| 3 | South Africa 1-2t/h Full Automatic Small Cookie Making Machine for sale |

| 4 | 900kg/h Professional Automatic Biscuit Making Machine for sale in Japan |

| Customer cases of Bakery Biscuit Making Machine repurchase in 2021 | |

|---|---|

| 1 | 800kg/h High Quality Industrial Biscuit Making Machine sold in the US |

| 2 | 300-500kg/h Biscuit Making Equipment sold in Germany |

| 3 | 500kg/h cost effective Biscuit Making Machine For Factory in Spain |

| 4 | 1t/h energy saving Biscuit Manufacturing Equipment for sale in Italy |

If you are interested in Cookies Machine Equipment, please feel free to contact us; we will provide you with the best price/performance solution in terms of Biscuit Machine Equipment Price And Quality.

Biscuit diagram

Frequently asked questions about cookie machinery

1. How to maintain the Biscuit Manufacturing Machine?

The maintenance of the Biscuit Manufacturing Equipment is to ensure the stable operation of the Biscuit Making Plant and extend the service life of the Biscuit Production Line.

1. First of all, the operator must understand the structure and operation of the Biscuit System and follow the instructions strictly when using it.

2. If the Automatic Biscuit Making Machine has been used for some time, the fabric will accumulate in the feed rollers and impression roller guards, which will aggravate the friction between the machines and produce noise impact, so the Biscuit Making Machine For Factory needs to be partially disassembled to remove the accumulation.

3. If Biscuit Manufacturing Equipment is not in continuous production and needs to stop, let the oven cool down, turn off the oven power, and idle for 20 minutes. At the same time, maintaining the conveyor belt can not produce damage, so you can stop all and turn off the power.

2. How do I make the tough dough?

In Biscuit Manufacturing Plant’s dough mixing machine, the gluten will be gradually relaxed after a long time of mechanical stretching, so it is necessary to make the dough longer to ensure that the protein is fully expanded and moistened to form gluten and then lose its strength after mechanical stretching, which meets the requirements of tough dough.

The modulation method is.

1. Stir sugar, milk, oil, egg, etc., with heated water in the Cookie Production Line mixer, and then add flour to make the dough.

2. After 10min of dough formation, improver can be added, and then puffing agent and flavoring can be added respectively, and then continue modulation.

3. Modulation time is 40min or more; you can get a tough dough.

3. How to store cookies in an Automated Cookie Factory?

Although cookies are storable foods, they need to be stored under certain conditions to maintain their freshness and taste to avoid softening or spoiling.

Cookies should be stored in a low-temperature, dry and airy environment, so the Biscuit Manufacturing Workshop should have a standardized temperature and humidity control system.

In addition to this, food safety should be put in the first place, and the daily cleaning work in the Biscuit Factory should be maintained while also avoiding the sunlight exposure of the food to reduce the storage length.