As a professional Biscuit Processing Manufacturer, with our many years of experience in Fully automatic biscuit processing technology, we have now achieved Fully automatic biscuit production and manufacturing on the Biscuit Project and have perfected it in terms of labour saving, energy saving, efficiency and noise handling.

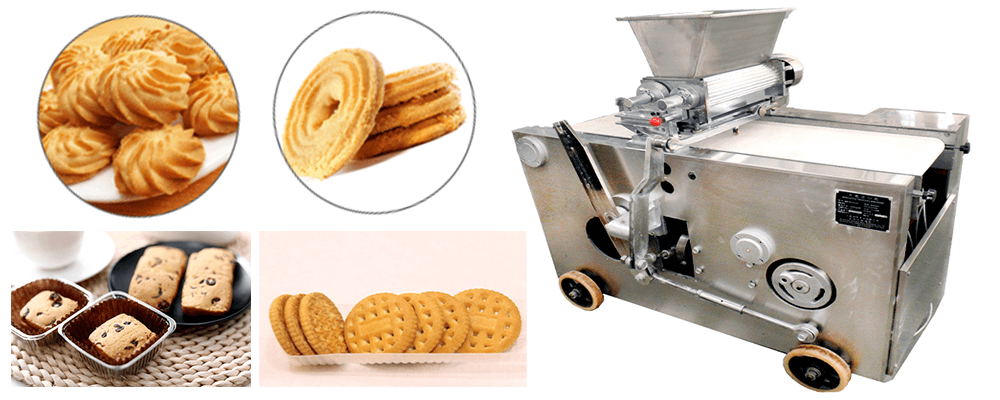

Biscuit machinery diagram

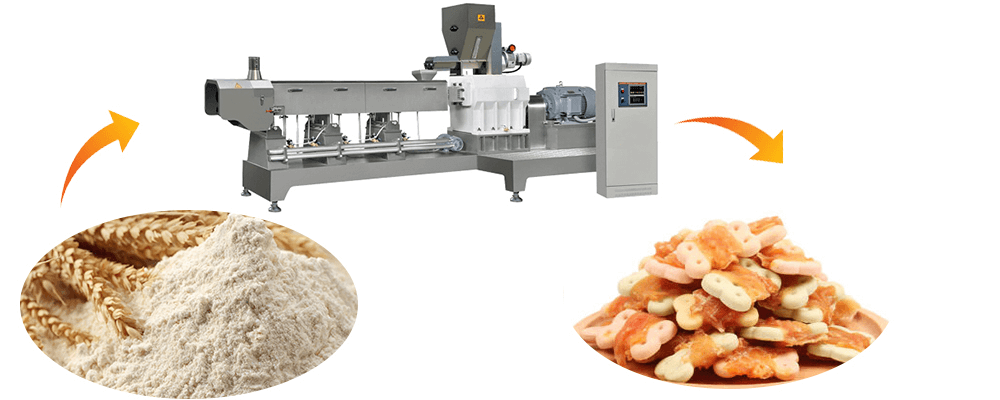

The raw material for the Biscuit Manufacturing Process is wheat flour with various additives such as sugar, fats, proteins and dairy.

We also provide you with a wide range of models and recipes in different shapes, which can be changed using Biscuit Manufacturing Equipment to produce a wide range of high quality biscuits.

Biscuit picture

We are committed to providing you with a long term after sales service after you have purchased your Biscuit Making Machine, which will guarantee you the correct and safe use of the Fully Automatic Biscuit Making Machine.

Your trust will be the driving force behind our Biscuit Machine Factory.

What are the advantages of the Automatic Biscuit Production Line?

The Fully Automatic Biscuit Making Machine can produce both tough biscuits and crisp biscuits, the Biscuit Processing Line uses a dual purpose machine head.

2. The Biscuit Making Machine can be adjusted to any thickness and transport speed, and the machine can be automatically switched off or alarmed in the event of a power leak.

3. The Biscuit Production Line has automatic temperature control, automatic baking, automatic conveying, automatic oiling and automatic cooling.

4. Automatic Biscuit Making Machine is controlled by double frequency converters, no need to adjust the empty travel, so that the Biscuit System can be achieved in one step, saving time and film.

5. The Biscuit Making Machine is equipped with a self-diagnostic function, which directly indicates when the Biscuit Manufacturing Units are faulty, making it more reliable and easy to maintain.

Biscuit Making Machine diagram

Process layout of the Biscuit Manufacturing Workshop.

| Biscuit Manufacturing Workshop Categories | ||

|---|---|---|

| 1 | Sugar melting room | This is the room where the sugar is dissolved and the syrup is prepared. When planning Biscuit Manufacturing Units, it is important to take into account the input of raw materials and their location. It should be located next to the aisle of the Biscuit Making Plant, with sufficient space and an exhaust fan to dissipate heat. |

| 2 | Forming room | The Biscuit Factory is equipped with a mixer and a forming machine. The control panel in the Biscuit Factory should be located close to the machine and there should be space for the stacking of material next to the machine. The Biscuit Making process should be well lit in order to better identify the quality of the material. |

| 3 | Baking room | A biscuit baking oven with sufficient space next to the oven for the installation and removal of electric heating elements. |

| 4 | Cooling room | The Automatic Biscuit Plant needs a good cooling system to allow the heat from the biscuits to escape to the outside. The control elements should also be isolated from the heat source and the console placed in the control room. The Biscuit Manufacturing Workshop should also be adequately lit in order to observe the heat of the biscuits. |

| 5 | Packing room | The Biscuit Manufacturing Plant requires good hygiene and adequate lighting. |

Technical parameters of Fully Automatic Biscuit Making Machine:

| Technical Parameters Of Automatic Biscuit Making Machine | |||

|---|---|---|---|

| Item | LY-1 | LY-2 | LY-3 |

| Voltage | 380V | 380V | 380V |

| Size(mm) | L12000*W1000*H2000 | L16000*W1100*H2200 | L30000*W1800*H2400 |

| Output | 200~300kg/h | 500~600kg/h | 700~800kg/h |

| Machine material | Stainless steel | Stainless steel | Stainless steel |

| Price | Us$4,000.00 | Us$5,000.00 | Us$6,000.00 |

| Automatic | Fully automatic | Fully automatic | Fully automatic |

| This is our updated list of Industrial Biscuit Making Machine in stock in 2022. If you need to verify or update, please contact us. | |||

Machine details

2021 Customer Order Automatic Biscuit Production Line Maker Form:

| Dealed Customer Have Plant Of Biscuit Manufacturing Plant | |

|---|---|

| 1 | 500kg/h Automatic Electric Industrial Commercial Biscuit Making Machine in Japan |

| 2 | 500-600kg/h China Ce Manufactory Automatic Biscuit Plant for France |

| 3 | America 1t/h Full Automatic Biscuit Making Plant |

| 4 | Russia 600kg/h Professional Biscuit Manufacturing Plant For Sale |

| Dealed Customers Who Repurchase Of Biscuit Making MachineAt 2021 | |

|---|---|

| 1 | Italy 600kg/h high Quality Biscuit Making Machine Technology |

| 2 | 600-700kg/h Easy Operation Industrial Biscuit Making Machine forThailand |

| 3 | 700kg/h Best Price Biscuit Production Line In Vietnam Factory |

| 4 | 1-2t/h Energy Saving Automatic Biscuit Production Line in Central Africa |

Biscuit pictures

1. How to better open a Biscuit Manufacturing Plant?

Firstly, it is important to understand that biscuit making is not only about the use and operation of the Cookie Production Line, it is also a process that requires different patterns.

The Biscuit Manufacturing Process goes through a series of processes such as blending, printing, baking, as well as cooling and packaging.

For a Biscuit Project brand in particular, it is important to be brand conscious, so that the patterns and prints are original and recognisable, as is the case with Biscuit Enterprise packaging.

In addition, food safety needs to be a priority, which means that the Automatic Biscuit Plant and raw materials need to be kept clean and hygienic.

2. What problems will occur in the Biscuit Manufacturing Process?

Each Biscuit Production Workshop and Biscuit Machine needs to maintain the right conditions and characteristics in order to maintain quality of the biscuits produced.

Some of the common problems that occur in the Biscuit Making Process are as follows.

1. Biscuit sticking to the bottom: this is due to the biscuits taking too long to cool down after baking, care should be taken that the temperature difference between the rear and middle zones of the Biscuit Making Plant is not too great and that the cooling time is not too long.

2. Biscuit shrinkage and deformation: The Cookie Production Line band is too tight, so adjust the band to keep it loose during transportation.

3. Blistering of biscuits: the temperature in the front of the oven is too high, so be aware that the temperature of the oven fire in the Biscuit Workshop is gradually increasing and should not be too high.

4. Cracking of biscuits: The strong heat exchange and evaporation of water after the biscuit has cooled too quickly from the oven can cause cracks in the biscuit. Avoid excessive cooling and use Biscuit Equipment such as temperature and humidity control to improve the situation.

3. How to keep the biscuits from deforming in a low temperature Biscuit Making Machine?

The main reason for shrinkage and deformation of biscuits is that the dough is not properly beaten, as Automatic Biscuit Making Machine is a 3-roller tie, there is no way to roll the dough well and therefore the biscuits do not shrink after the biscuit roll is cut. The following measures can be effective in alleviating this.

1. add moisture to the head of the Biscuit Manufacturing Equipment machine.

2. Control the amount of water added to the Biscuit Project, use warm water to stir the dough.

3. Make sure that the recipe is reasonable and that the ingredients are in the correct proportion.

4. Do not mix the flour too long to avoid gluten.