The soft biscuit forming machine is mainly used to process biscuits of various shapes and some low-fat biscuits. Put the mixed flour into the machine, and then roll and shape it into a biscuit embryo, and put it in the oven to make all kinds of medium and high-grade biscuits. It has the characteristics of no rust, small footprint, longer service life, clean production process and high safety.

The characteristics of crisp biscuits are that the impressions are mostly convex, with obvious patterns and fine structures, which are 14% to 30% of the flour content. For some special products with loose sweetness, the amount of oil and fat can be as high as 50%.

Recipe of Soft Biscuit Forming Machine

Wheat flour, sugar and oil are used as the main raw materials, and bulking agents and other auxiliary materials are added. The shapes made by powder mixing, rolling, rolling printing or punching and baking through the cold powder process are mostly convex, and the cross-sectional structure presents a porous structure. , Loose-tasting baked goods. Such as cream biscuits, scallion biscuits, sesame biscuits, etc.

Price of Soft Biscuit Forming Machine

| Name | Model | Power | Capacity | Price |

|---|---|---|---|---|

| Biscuit forming machine | LY225 | 35kw | 50kg/h | 200usd |

| LY 280 | 65kw | 80-100kg/h | 280usd | |

| LY 320 | 85kw | 100-150kg/h | 500usd | |

| LY 400 | 100kw | 150-200kg/h | 550usd | |

| Model 600 (electric or gas) | 300kw (45kw) | 400-500kg/h | 600usd | |

| Model 800 (electric or gas) | 55kw | 700kg/h | 680usd | |

| Model 1000 (electric or gas) | 60kw | 900-1000kg/h | 800usd | |

| The biscuit shaping machine price is a promotional price in 2022, update price. Check with our biscuit machine team. Biscuit making machine price | ||||

Parameter of Soft Biscuit Forming Machine

| Name | Parameter |

|---|---|

| Effective Width (Mm) | 40-1500 |

| Production Capacity (Kg/h) | 400-2 000 |

| Normal Working Noise d (A) | ≤8O |

| Mean Trouble-Free Working Time (h) | ≥600 |

| Pie Die Line Speed (m/Min) | 8~35 |

| Bearing Temperature Rise (°c) | E35 |

| Bearing Maximum Temperature (°c) | ≤65 |

Principle Of Soft Biscuit Forming Machine

Roll printing biscuit forming machine is usually used for the production of high-fat biscuits. Generally, the dough is directly pressed into the cake mold through a pair of wheels, and the excess dough is scraped off with a scraper pressed on the cake mold, and then the biscuit blank is used. Release from the cake mold onto the conveyor belt.

Soft Biscuit Forming Machine Performance

| Molding Machine Quality | It Meets The Requirements Of Strict Standards And Is Manufactured According To The Drawings And Technical Documents Approved By The Prescribed Procedures. |

| Molding Machine Operation: Reliable And Stable Operation, Flexible Movement During Operation, No Abnormal Sound. Each Group Of Rolling Series Has a Thickness Adjustment Device; Each Conveyor Belt Runs | The Operation Is Not Stagnant, Rubbing Edges, And There Is a Control Deviation Device. |

| Selection Of Molding Machine Material And Safety And Hygiene Of Equipment Structure | Comply With The Regulations Of Gb 16798 And Gb 19891. |

| Basic Technology Of Molding Machine | Comply With The Regulations Of Sb/T 224. |

| Parts That Need To Be Disassembled For Cleaning | Its Disassembly And Installation Are Simple And Convenient |

| Non-Removable Parts | It Can Be Washed Directly And The Cleaning Effect Is Good. |

| Raw Materials Used, Purchased Accessories | Meet The Requirements For Use, And Have The Quality Certificate Of The Manufacturer. Otherwise, It Can Be Put Into Use Only After Passing The Acceptance According To The Relevant Standards Of The Product. |

| Product Parts Machined Surface | Comply With The Provisions Of Gb/T 1031. |

| The Outer Surface Of The Molding Machine | Clean, Flat, Smooth, Without Visible Damage. |

| Parts And Components Of The Molding Machine That Are In Direct Contact With Food | The Surface Conforms To The Regulations Of Gb 16798 And Gb 19891. |

| Forming Machine Electroplating Parts | The Coating Is Smooth, Fine And Uniform In Color. |

| Forming Machine Spray Paint Parts | The Paint Surface Is Smooth, Firm, Bright And Uniform In Color. |

Features of Soft Biscuit Forming Machine

- 1. Stainless steel outsourcing, corrosion resistance, no rust!

- 2. The structure of the whole machine is exquisitely designed and occupies a small area!

- 3. The wall panels use strong thickened steel plates, which have a longer service life!

- 4. The conveyor belt is made of PVC material, which is automatically cleaned and the production process is clean and hygienic!

- 5. Frequency control of production speed, convenient operation and high safety!

- 6. Three-level adjustment handle, easy to adjust, and the demoulding rate is as high as 100%!

- 7. The mold patterns are diverse, which can meet the needs of personalized customization!

Material of Soft Biscuit Forming Machine

| 1. Side board | Using Q235 carbon steel material, the thickness after processing is 28mm, the surface is hard chrome plated, and the surface hardness is HRC58-62 |

| 2. Conveyor rack plate | Using Q235 carbon steel material, the thickness after processing is 15mm, the surface is plated with hard chrome, and the hardness is HRC58-62 |

| 3. Pallet | Use 304 stainless steel |

| 4. Mould and conveyor belt | Controlled by independent motors, easy to adjust |

| 5. Mould and rubber roller | The pressure between these two is adjusted using a motor, and the scraper is manually adjusted using a cam |

| 6. Conveyor belt | Pneumatic tensioning and pneumatic offset adjustment are adopted, and the cylinder uses the Korean famous brand YSC; |

| 7. Enclosure | Use 1.5mm304 stainless steel material |

| 8. Idler, transition knife, etc. | Hard chrome plating on the surface |

| 9. Main motor, reducer | With SEW/Siemens, frequency control |

| 10. Mold | Pressure is detected by displacement sensor, accurate digital display, speed and gap touch screen control |

| 11. Control electrical appliances | Mainly use French brands: Schneider |

| 12. Bearings | Use Japanese brand: NSK |

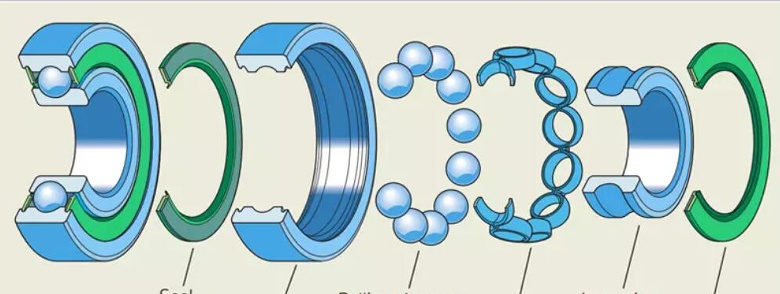

Features of SFK bearings:

SKF is a leader in bearing technology and manufacturing. More than 80% are supplied by SKF’s steel mills, which guarantee the high quality of raw materials. All important equipment is designed and assembled by SKF to ensure the highest level of production equipment. SFK bearings have the advantages of higher rated load, lower noise, greatly reduced warranty costs, and increased machine running time. The strong combination of machines made by Shandong loyal and SFK accessories is the greatest benefit of our customers. Not only provide you with a turnkey project from Z to Z, but also provide the highest quality assurance from small parts to a complete production line to reduce your worries in the business development stage.

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

|---|---|---|---|---|---|---|---|

| Dynamic | Static | Reference speed | Limiting speed | ||||

| D[mm] | D[mm] | B[mm] | C[kn] | Co[kn] | [r/min] | [r/min] | |

| 4204 atn9 | 20 | 47 | 18 | 17.8 | 12.5 | 24 000 | 13 000 |

| 4304 atn9 | 20 | 52 | 21 | 23.4 | 16 | 22 000 | 12000 |

| 6004 | 20 | 42 | 12 | 9.95 | 5 | 38 o00 | 24 000 |

| 20 | 42 | 12 | 9.95 | 5 | 38 o00 | 24 000 | |

| 20 | 42 | 12 | 9.95 | 5 | 11 000 | ||

| 20 | 42 | 12 | 9.95 | 5 | 38 o00 | 19 000 | |

Features Of Schneider Motor Reducer

Schneider motor reducer: high precision, high rigidity, high load, high efficiency, high speed ratio, long life, low inertia, low vibration, low noise, low temperature rise, beautiful appearance, light and small structure, easy installation, precise positioning, etc. It is suitable for the acceleration and deceleration transmission of AC servo motor, DC servo motor, stepper motor and hydraulic motor.

| Accessories for biscuit production line | |||

|---|---|---|---|

| Brand | Schneider | Allowable Torque | 22n.m |

| Type | Bevel Gear Reducer | Load State | Uniform Load |

| Gear Ratio Series | Stepless | Relative Position Of The Axis | Horizontal Reducer |

| Input Speed | 3000rpm | Rated Power | 111kw |

| Output Speed Range | 40rpm | Tooth Surface Hardness | Soft Tooth Surface |

| Layout Form | Coaxial | Use | Reducer |

Maintenance And Cleaning Of Soft Biscuit Forming Machine

The raw materials of the biscuit forming machine are brass and rubber, no sticking, no residue, easy to clean up. We provide a one-year warranty, and free replacement parts within one year and within the warranty period. We have a professional technical team to provide online technical support. If you have any questions, you can communicate with our engineers with 10 years of work experience to provide you with satisfactory pre-sales and after-sales services