As a Biscuit Machinery Manufacturer with many years of experience, LOYAL has always been a world leader in the Biscuit Machinery industry.

LOYAL has always been a world leader in the Biscuit Machinery industry, and our Biscuit Making Equipment is the result of our investment in research and development and our highly paid professional engineers.

LOYAL has a unique research in Biscuit Making Machines and has the most advanced Biscuit Making Process in the industry, providing the most cost effective Cookie Making Machines for Biscuit production factories.

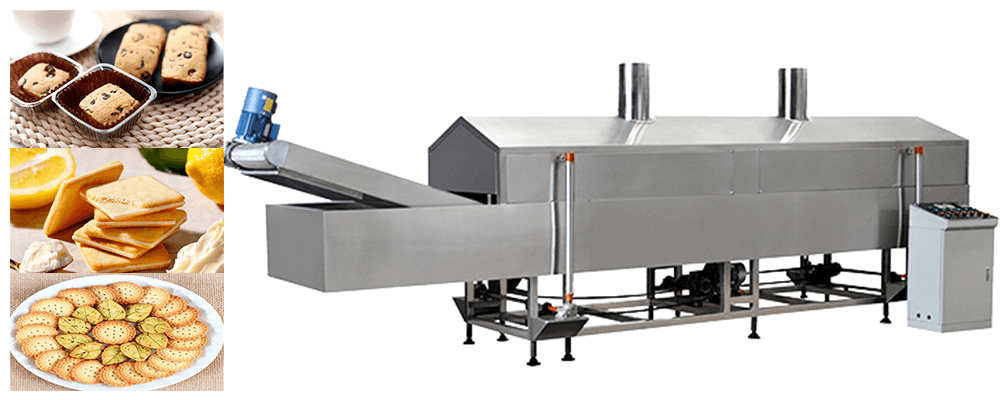

Our Small Biscuit Making Machine is capable of producing many different types of biscuits including soda biscuits, sandwich biscuits and wafers.

Biscuit Making Machine

What is a Small Cookie Making Machine?

The Industrial Biscuit Making Machine is a fully automated Biscuit Equipment, the Biscuit Manufacturing Process is very advanced.

The biscuit manufacturing process is very advanced and consists of a mixer, a forming machine, an oven, an oiling machine and a cooling belt.

Biscuit making machines

The production process of the Biscuit Making Machine For Factory.

Pre-treatment of raw materials – Dough preparation – Rolling of the dough sheet – Pressing into biscuit shapes – Baking – Spraying with oil – Cooling – Packaging.

Biscuit production flow chart

The detailed process flow of the Automatic Biscuit Making Machine is shown below.

| Biscuit Line Process Flow | |

|---|---|

| Pre-treatment of raw materials | This includes the pre-treatment of flour, sugar fats, dairy and egg products as well as bulking agents and salt. |

| Dough preparation | For shortbread biscuits, the shortbread dough is made using the cold flour shortening method and for tough biscuits, the tough dough is made using the hot flour toughness method. |

| Rolling the dough sheets | The prepared dough is rolled to a uniform thickness, flat shape, smooth surface and fine texture to prepare it for moulding. |

| Pressing into biscuits | Different molds are used to cut the dough into different biscuit shapes. |

| Baking | The biscuits are baked at high temperatures to mature. |

| Oiling | The biscuits are sprayed with rapeseed oil, etc. to give them an attractive golden colour. |

| Cooling | Cooling and packaging further improves the quality of the packaging. |

| Packaging | After packaging the biscuits are of a higher quality and look better. |

Biscuit processing line in detail

Technical data relating to the Biscuit Processing Line.

| Automatic Biscuit Production Line specifications | |||

|---|---|---|---|

| Models | 01 | 02 | 03 |

| Power | 100kw | 150kw | 200kw |

| Outputs | 100-200kg/h | 250-350kg/h | 300-400kg/h |

| Weight | 1000kg | 2000kg | 3000kg |

| Biscuit Making Machine Price | Us$10,000.00 | Us$20,000.00 | Us$30,000.00 |

| These are the updated promotional prices for Biscuit Production Line in 2022. For more details, please contact our Cookie Production Line team. | |||

Picture of the finished biscuit

2021 Customer Order Biscuit Manufacturing Equipment Maker Form:

| Dealed Customer Have Plant Of Commercial Biscuit Making Machine | |

|---|---|

| 1 | 200-300kg/h Russia Biscuit Processing Line |

| 2 | 500kg/h Biscuit Line In Nigeria |

| 3 | Pakistan 300-400kg/h Automatic Biscuit Production Line |

| 4 | 1-2t/h Biscuit System For Sale In Indonesia |

| Dealed Customers Who Repurchase Of Small Cookie Machine At 2021 | |

|---|---|

| 1 | 800kg/h Germany Biscuit Manufacturing Process |

| 2 | France 500-800kg/h Cone Biscuit Making Machine |

| 3 | 600kg/h Biscuit Making Equipment In Italy |

| 4 | South Korea 3t/h Biscuit Production Technology |

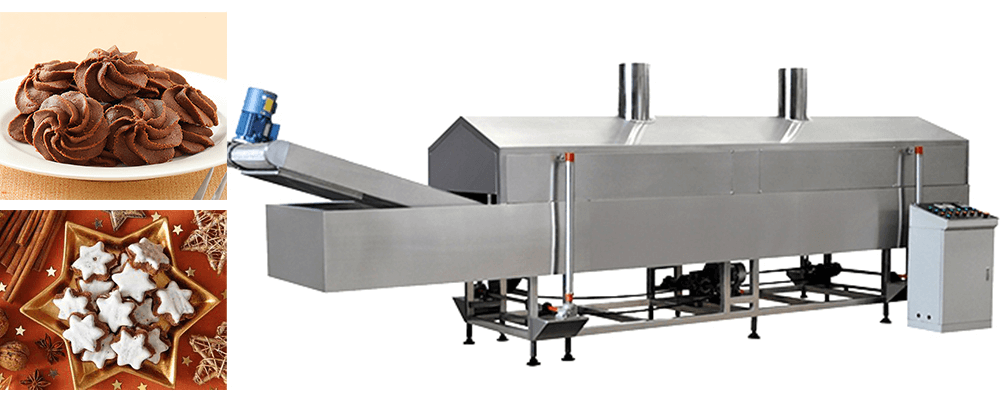

Picture of the finished biscuit

1. What are the advantages of Biscuit Making Equipment?

1.Biscuit Making Machine is equipped with variable frequency speed control for all kinds of machines.

The various machines work well together and are truly automated.

2. The tunnel type electric baking oven uses energy-saving quartz electric heating tubes, which provide sufficient heat radiation and fast heating up.

At the same time, energy saving technology is adopted, which can save up to 30% of energy during normal operation.

3. The Biscuit System is frequency-controlled, easy to operate and quick for workers to get started.

4. Biscuit Line is made of food-grade stainless steel, which is durable and has a long service life.

The Commercial Biscuit Making Machine makes the Biscuit Manufacturing Process of Automatic Biscuit Plant simple and convenient. The Cookie Making Machine not only reduces the number of intermediate steps, but also reduces the number of manual operations.

2. Support equipment to buy with Biscuit Production Line

Biscuit Manufacturing Units uses only Automatic Biscuit Production Line for the production of a wide range of biscuits.

The use of the Automatic Biscuit Production Line alone is not sufficient, but a combination of supporting equipment is required to enable the Biscuit Project to run smoothly.

The Biscuit Processing Line is equipped with a wide range of auxiliary equipment, such as sugar and salt spreaders, oil sprayers, syrup sprayers, multifunctional dusters, trough biscuit cutters, differential biscuit cutters and nut slicers, which facilitate the production of a wide range of biscuit flavours.

3. What are the main applications of the Small Biscuit Making Machine?

The Biscuit Making Machine For Factory is one of the most used Biscuit Equipment in the Biscuit Making Plant.

The Biscuit Manufacturing Machine helps Biscuit Manufacturing Plants to produce many different types of biscuits, such as shortbread, tough biscuits, wafers, chocolate biscuits, soda biscuits and biscuits, simply by changing the Biscuit production process, which is very versatile.