As one professional biscuit biscuit making machine manufacturer, we can offer small, medium and large biscuit biscuit making machine for sale. The biscuit biscuit making machine has reasonable price, reliable quality and professional service! Our company provides customers full set service: Cost accounting, biscuit making machine design, biscuit recipes, machine installation and debugging, design biscuit molds according to customer requirements.

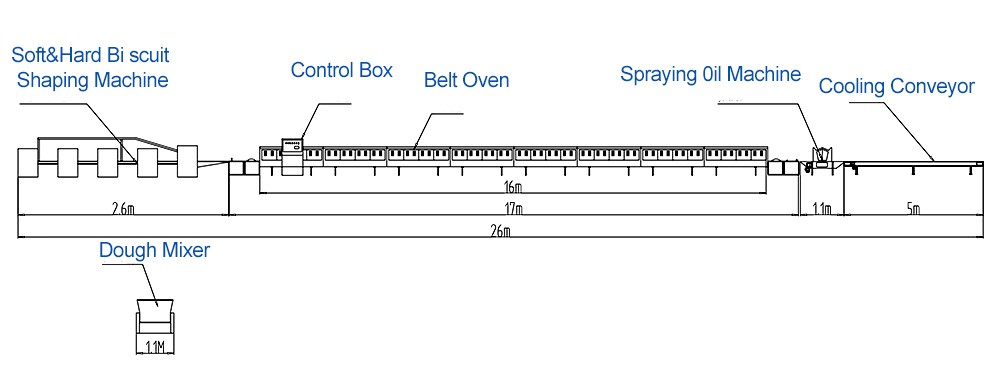

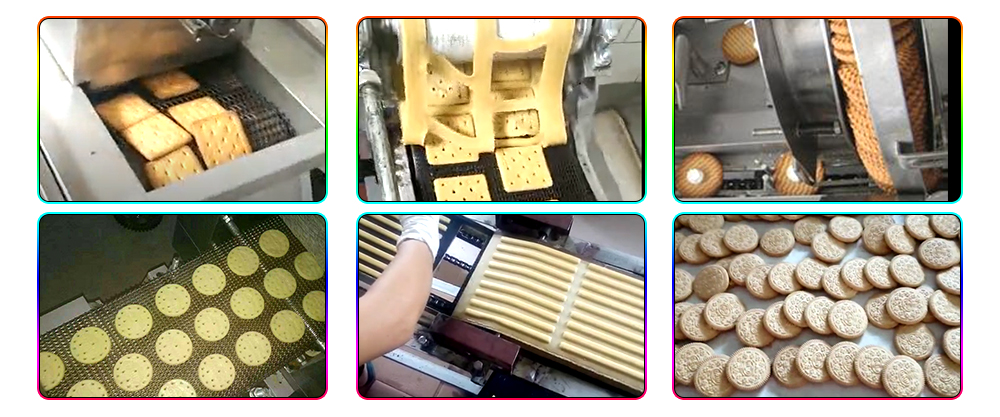

The biscuit making processes is composed of biscuit forming machine, electric oven, oil injection machine, turning machine, cooling line, biscuit finishing machine, packaging table, etc. The whole line is controlled by CPU module, driven by a back-mounted motor, with a compact structure and a high degree of automation. The equipment can also produce high-quality biscuits of various flavors, such as cream, jam, etc. The biscuit production line adopts advanced technology at home and abroad, and uses the highest quality food-grade materials, allowing manufacturers to produce various types of chocolate sandwich biscuits, hard biscuits and soda biscuits according to market demand. The equipment has very mature technology, the control and operation of key components are more accurate and safe, and the manufacturer can provide perfect after-sales service. It is a high-quality equipment that major biscuit manufacturers are competing to buy.

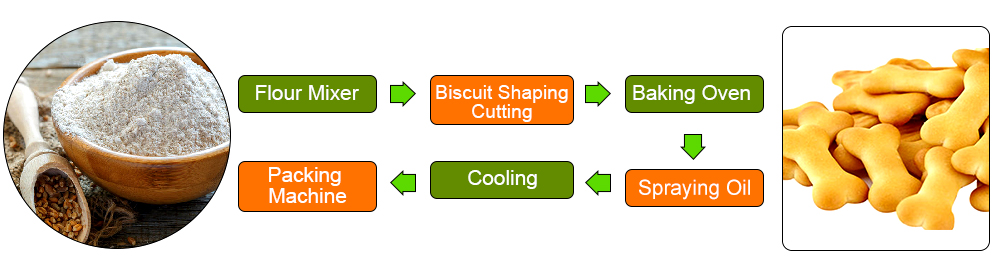

CRACKER PRODUCTION PROCESS

First, you need to prepare all the raw materials and flour, according to the recipe to ensure that the amount of ingredients is accurate. Then put these ingredients in the dough mixer and mix. The dough formed next will enter the compound rolling forming machine including rolling printing, rolling cutting, and forming various shapes of biscuits according to the machine model. After the biscuit shape is completed, the biscuits will enter the baking box for baking. Then the biscuits enter the oil injection machine for seasoning and oil injection. After the oil injection is completed, the biscuits enter the cooler for cooling. Finally, they are packaged.

WHAT MATERIALS ARE USED TO MAKE BISCUIT?

| Biscuit Recipe | |

|---|---|

| Soft Biscuit | Hard Biscuit |

| Flour: 25kg | Flour: 25kg |

| Sugar: 6kg | Sugar: 4kg |

| Palm Oil: 6kg | Palm Oil: 2.5kg |

| Butter: 0.5kg | Milk Powder: 0.25kg |

| Water: 2.5kg | Water: 6kg |

| Syrup: 300g | Syrup: 0.5kg |

| Ammonium Bicarbonate: 100g | Ammonium Bicarbonate: 0.5kg |

| Baking Soda: 100g | Baking Soda: 200g |

| Salt: 150g | Sodium Metabisulfite: 20g |

| Starch: 1kg | Flavor: 15g |

| Vanillin: 15g | |

HOW DO YOU START A BISCUIT FACTORY?

| Automatic Biscuit Making Plant | |

|---|---|

| To establish a small food processing plant, there are two situations: | |

| 1. Self-employed | |

| 2. Company | |

| In either case, a food production license is required, which is handled at the local Food and Drug Administration, provided that a business license for industry and commerce is obtained. | |

| To apply for a food production license, the following must be met: |

|---|

| 1.To apply for a food production license, one should first obtain a business license and other legal subject qualifications. |

| 2.Application for food production license. Other conditions stipulated by laws and regulations. |

| Process design requirements for biscuit food clean workshop: |

| Although the process of biscuit production varies with the variety, in general, the process can basically be summarized as: ingredients, powder mixing, forming, baking, cooling, and packaging. According to the process requirements, the biscuit workshop usually has a sugar-dissolving room, a forming room, a baking room, a cooling room, and a packaging room. If soda biscuits are produced, a fermentation room should also be set up. |

IS BISCUIT MANUFACTURING PROFITABLE?

As a giant in the food business, biscuits have a very broad development prospect. Food, clothing, housing and transportation are the biggest needs, especially after living conditions are better, people also pay special attention to diet, hoping to taste those more delicious ingredients. Many entrepreneurs have also seized the opportunity to grow and develop in their respective fields, leading the company to become a unicorn in the segmented field.

In the food industry, Nestle is a well-deserved giant, occupying the world’s No. 1 position in terms of revenue, but Kraft Heinz is the second place, with 100,000 employees worldwide and a business layout of more than 70 It has a net profit of 10.999 billion US dollars, which is higher than Nestle and ranks first, which means that it makes an average of 200 million yuan a day. Its total revenue also reached 26.232 billion US dollars, and Buffett also recognized it very much, occupying 27% of the shares.

WHO IS LOYAL PRIMARY CUSTOMERS OF BISCUIT MACHINE?

| Cooperated Customer With Automatic Biscuit Making Plant Technology At 2021 | |

|---|---|

| 1 | China 300t/Year Industrial Automatic Biscuit Making Plant |

| 2 | 1T/H Tough Automatic Biscuit Making Plant For Sale In Puerto Rico |

| 3 | Senegal 1T/H Industrial Biscuit Biscuit Making Machine |

| Second- Cooperation Customers Of Biscuit Biscuit Making Machine At 2021 | |

|---|---|

| 1 | 1T/H Biscuit Making Machine For Sale In Côte d’Ivoire |

| 2 | 1T/H Biscuit Making Machine Sold In Russia |

| 3 | 1T/H Biscuit Making Machine For Sale In Uzbekistan |

| Cooperated Customer Finished Plant Of Biscuit Biscuit Making Machine At 2021 | |

|---|---|

| 1 | 1000kg/h Industrial Automatic Butter Biscuit Making Machine For Sale In Senegal |

| 2 | Mozambique 1T/H Industrial Butter Biscuit Making Machine |

| 3 | 1T/H Thai Butter Biscuit Making Machine |

| Cooperated Customer Which Producing High-Classic Product | |

|---|---|

| 1 | Austria Sells Industrial Biscuit Machine 100kg/h |

| 2 | Algerian Biscuit 300kg/h Production Line |

| 3 | 800kh/h Industrial Biscuit Machine In Nigeria |