LOYAL is a company specializing in the production of various types of Cookie Making Machines . Based on advanced technology and exquisite Biscuit Equipment processing technology, and with the tenet of quality first and credit first, we professionally manufacture Small Biscuit Making Machine. Today, Small Cookie Making Machine has been exported to many countries and regions around the world .

Industrial Biscuit Making Machine can adjust the Biscuit Manufacturing Process according to the needs of Biscuit Manufacturing Units . It only needs to be adjusted properly at one time, and it can be used for a long time . At the same time, the Bakery Biscuit Making Machine also has very stable performance, which can process and produce crispy biscuits and tough biscuits. , cream biscuits and sandwich biscuits and many different types of biscuits.

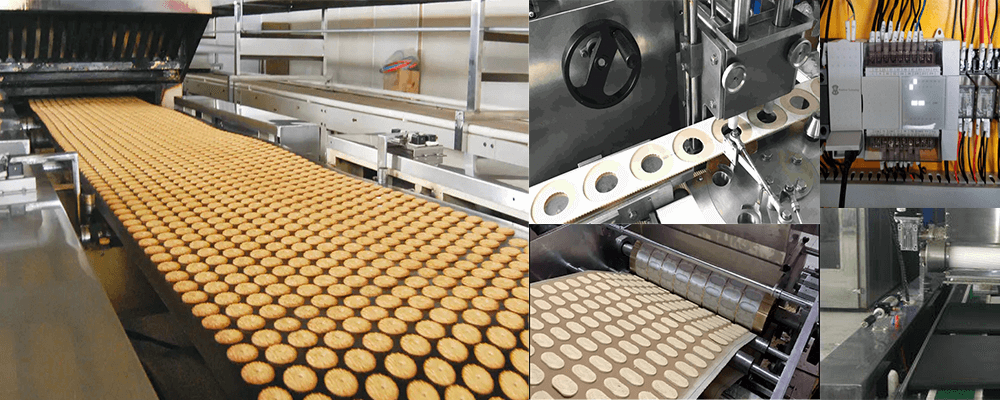

Biscuit Mechanical Drawing

What is Meal Replacement Biscuit Production Line?

Biscuit Production Line is a professional Biscuit Equipment that can realize fully automated production methods. The meal replacement biscuits produced have rich taste and strong satiety, which are favored by consumers. Not only that, the Automatic Biscuit Making Machine can serve different Biscuit Projects , which can provide very high economic benefits to the vast Biscuit Manufacturing Plant , and is an ideal choice for expanding the biscuit market.

The process flow of Biscuit Making Machine For Factory :

Kneading – biscuit forming (crisp/toughness) – salt and sugar seasoning – baking – oil spraying – cooling – differential biscuits – packaging .

Mechanical flow chart

Process steps of Cookie Production Line:

| Process steps of Biscuit Manufacturing Equipment | |

|---|---|

| noodles | Add the appropriate amount of water to the dough mixer and knead the various ingredients into a flexible dough. |

| forming | The prepared dough is rolled into the Commercial Biscuit Making Machine to form biscuits of various shapes and weights. |

| bake | Roasted on high heat in the oven for a crispy texture. |

| cool down | The cooling treatment is carried out in the cooling line, and it is not easy to return to moisture after cooling. |

| fuel injection | The color of the biscuits will be more attractive after the oil sprayer sprays cooking oil on the biscuits. |

| tidy | Use a finisher to stack cookies. |

| Package | Use a packaging machine for packaging processing. |

Different specifications of the Biscuit Processing Line :

| There are technical data about Automatic Biscuit Production Line | ||||

|---|---|---|---|---|

| Model | 01 | 02 | 03 | 04 |

| Voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Power | 50kw | 120kw | 200kw | 250kw | Yield | 50-120kg/h | 100-200kg/h | 200-300kg/h | 400-500kg/h |

| working width | 200mm | 200mm | 200mm | 200mm |

| Baking temperature | 200-300℃ | 200-300℃ | 200-300℃ | 200-300℃ |

| Automatic Biscuit Making Machine Price | Us$ 1,000.00 | Us$ 2,000.00 | Us$ 2,500.00 | Us$ 4,000.00 |

| production line length | 15m | 18m | 18m | 20m |

| Package | General use is ordinary packaging, according to the different regions of Biscuit Making Plant , it is packed in ordinary or wooden boxes. | |||

| The above is the promotional price of the updated 2022 Biscuit System , please contact our Biscuit Line professional technical team for more details . | ||||

Cookie chart

2021 Customer Order r Meal Replacement Biscuit Production Line Maker Form:

| Dealed Customer Have Plant Of Cookie Making Machine | |

|---|---|

| 1 | 300-500kg/h Customized Small Cookie Making Machine In Japan |

| 2 | Canada 800kg/h 304 Stainless Steel Industrial Biscuit Making Machine |

| 3 | 1-2t/h Ce, Iso9001 Bakery Biscuit Making Machine In Netherlands |

| 4 | Germany 3t/h Multi-function Biscuit Making Machine For Factory |

| Dealed Customers Who Repurchase Of Small Biscuit Making Machine At 2021 | |

|---|---|

| 1 | 5t/h No Noise Biscuit Manufacturing Technology For Sale In Austria |

| align=”center”2 | Australia 600-700kg/h Energy Saving Automatic Biscuit Making Machine |

| 3 | Norway 100-200kg/h No Pollution Commercial Biscuit Making Machine |

| 4 | America 300kg/h Siemens Motor Biscuit Manufacturing Process |

Cookie chart

1. What are the advantages of Meal Replacement Biscuit Production Line ?

1. The Industrial Biscuit Making Machine has a compact structure and a small footprint, the Biscuit Manufacturing Machine price is low, and the investment cost of the Automatic Biscuit Plant is small.

2. The oven has good thermal insulation performance, the color and aroma of the biscuits produced are very good, and the long-term economic benefits are good, and it has the characteristics of energy saving.

3. There are various kinds of biscuits produced, and biscuits of various shapes can be produced by changing the mold.

4. PLC control system, easy to operate, the entire production line only needs 1-2 people to complete the production.

5. The Biscuit Making Process is advanced and is at the leading level in the biscuit industry.

2. What are the raw materials used by Biscuit Manufacturing Equipment?

Meal Replacement Biscuit Production Line to make biscuits are ghee, butter, white sugar, egg yolk, milk, low-gluten flour, whipped cream, etc. If you’re a baking lover, you can also try making your own cookies using these ingredients.

3. Automatic Biscuit Production Line Validation Documents

Cookie Making Machine has been certified by CE, ISO, FDA and other international organizations, has very high quality standards, meets the needs of the food processing industry, and can provide Biscuit Manufacturing Units with very high economic benefits, if you need it If so, please contact us and we will provide you with the relevant certification.

Meal Replacement Biscuit Production Line Vido