Multifunctional B iscuit Production Line can meet a variety of biscuit needs . Choose Loyal and any specification about the Cookie Making Machine can be customized. At the same time, Industrial Biscuit Making Machine with higher capacity can also be provided according to the different requirements of Biscuit Manufacturing Units and the size of the factory . The biscuit line has many models and specifications, which can meet the needs of different manufacturers and bring a lot of convenience to Biscuit Manufacturing Units .

Loyal Biscuit Manufacturer has invested a lot of money and professional Biscuit Manufacturing Process engineers to develop a high-quality Commercial Biscuit Making Machine , and finally developed the Automatic Biscuit Production Line machine with superior quality and stable performance, which can produce a variety of shapes and flavors. Biscuit has a very high evaluation among consumers. Biscuit Production Line is also an ideal choice for biscuit manufacturers to expand the market.

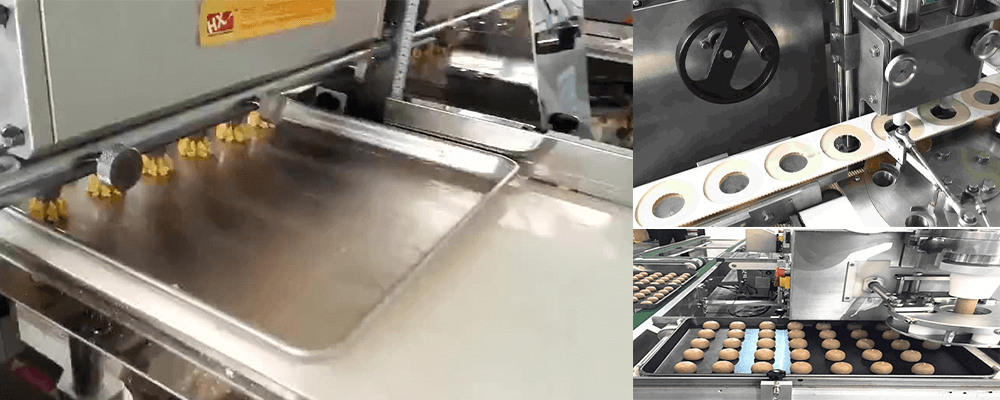

The workflow of Multifunctional B iscuit Production Line :

Dough making —> Biscuit forming and baking —> Injection molding machine —> Cooling —> Biscuit stacker —> Biscuit filling machine Biscuit finishing table —> Final packing machine

The entire process of Automatic Biscuit Production Line is an assembly line operation, including feeding, pressing, forming, scrap recycling, material distribution, baking, oil injection, cooling.

Biscuit manufacturers can produce popular high-end biscuits on the market, including butter biscuits, biscuits, thin biscuits, Dove soda biscuits, as well as animal biscuits, biscuits, vegetable biscuits, etc., by changing the mold and Biscuit Manufacturing Process formula .

Technical parameters of Automatic Biscuit Production Line:

| Industrial Biscuit Making Machine Model | DL-250 | DL-400 | DL-600 | DL-800 | DL-1000 | DL-1200 |

| Handling capacity (KG/H) | 100 | 250 | 500 | 750 | 1000 | 1250 |

| Total length (mm) | 29600 | 64500 | 85500 | 92500 | 125000 | 125000 |

| Baking temperature(℃) | 190-240 | 190-240 | 190-240 | 190-240 | 190-240 | 190-240 |

| Power (KW) | 65 | 190 | 300 | 380 | 700 | 830 |

| Weight (KG) | 6000 | 12000 | 20000 | 28000 | 40000 | 45000 |

What are the advantages of Multifunctional B iscuit Production Line ?

| Main Features of Automatic Biscuit Making Machine | |

|---|---|

| 1 | Biscuit formers can be connected directly to the Biscuit Production Line or manually placed into the product. |

| 2 | Biscuit Manufacturing Equipment is designed according to product characteristics to avoid product extrusion. When the product is in a fault state, the unqualified equipment will be dismantled without stopping to ensure the continuous and stable production and packaging process. |

| 3 | Multifunctional Biscuit Production Line adopts multi – frequency control, servo drive control, easy operation, stable operation, high control precision and low energy consumption. |

| 4 | Bakery Biscuit Making Machine adopts stainless steel and aluminum alloy structure, humanized design, easy installation, maintenance and maintenance. |

| 5 | Automatic Biscuit Making Machine Automatic feeding: centering, positioning, dispensing, packaging. |

Automatic Biscuit Making Machine meets the requirements of domestic and foreign markets, and has won wide recognition and praise from customers at home and abroad . High quality and multi-function are the main features of Biscuit Making Machine .

2021 Customer Order r Biscuit Production Line Maker Form:

| Dealed Customer Have Plant Of Cookie Production Line | |

|---|---|

| 1 | India 1-2t/h No Pollution Biscuit Manufacturing Equipment |

| 2 | Egypt 200kg/h No Noise Commercial Biscuit Making Machine |

| 3 | 800kg/h Multi-function Biscuit Processing Line For France |

| 4 | 1t/h Italy Customized Automatic Biscuit Production Line |

| Dealed Customers Who Repurchase Of Biscuit Line At 2021 | |

|---|---|

| 1 | Turkey 300-500kg/h Ce, Iso9001 Sakura Biscuit Production Line |

| 2 | Brazil 600-700kg/h 304 Stainless Steel Biscuit Making Machine For Factory |

| 3 | 400kg/h High Efficiency Biscuit Making Technology In Switzerland |

| 4 | 2t/h Saving Labor Biscuit Manufacturing Process In Netherlands |

1. How Multifunctional Biscuit Production Line Works

Cookie Making Machine mainly uses wheat flour, eggs, white sugar, dairy products and leavening agents as the main raw materials. The raw materials are kneaded into dough in the mixer, and then sent to the oven matched with the Small Biscuit Making Machine for high-temperature baking. After finishing, use the oil sprayer of Biscuit Processing Line to spray cooking oil on the surface of the biscuits to make the biscuits richer in color. At this time, the temperature of the biscuits is relatively high, and a cooling line needs to be used for cooling treatment, which can effectively prevent the biscuits from returning to moisture and softening and affecting the quality. After cooling, the packaging machine can be used for packaging.

2. Support Equipment to buy with Multifunctional Biscuit Production Line

We can provide various types of Biscuit Manufacturing Equipment for the majority of Biscuit Manufacturing Plants , and can also provide some auxiliary Biscuit Equipment , so that the entire Cookie Production Line has a fully automated production method and further reduces labor costs. Feeder, weighing machine, nut slicer , sugar and salt spreader, oil sprayer, syrup sprayer, multi-function duster, trough type cake handler, differential cake handler, etc.

3. Industries using Multifunctional Biscuit Production Line

Biscuit Manufacturing Equipment is a versatile biscuit equipment that produces many different types of biscuits. There are two main types of biscuits on the market, namely, tough biscuits and crisp biscuits. It is only necessary to adjust the Biscuit Manufacturing Process of Biscuit System , and the Biscuit Processing Line can process and produce various tough biscuits and crisp biscuits. We can also provide novel molds for the majority of Biscuit Manufacturing Plants , helping Biscuit Manufacturing Units to further improve their market competitiveness.

Multifunctional Biscuit Production Line Vido