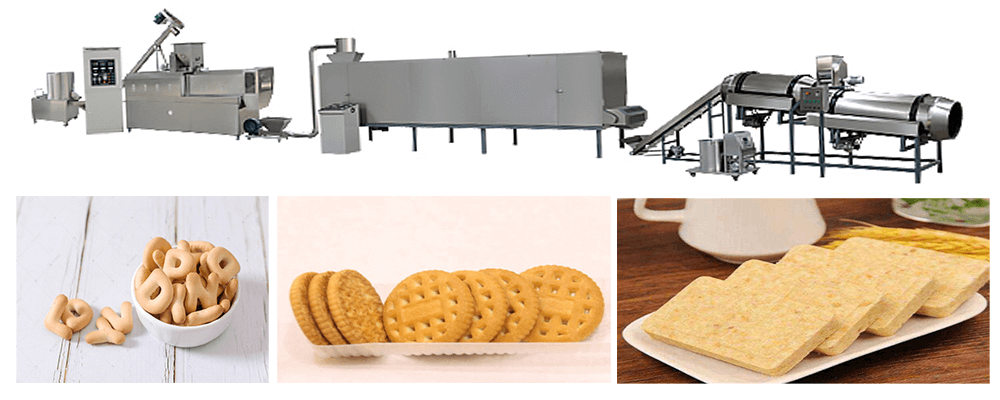

LOYAL is a leading Biscuit Machinery Manufacturer in the industry. Over the years, the company has been based on the domestic market and expanded into the international market. Biscuit Processing Line is sold all over the country and exported to Southeast Asia, South Asia, South America, the Middle East, Eastern Europe and Africa and other countries and regions , Biscuit Machinery ‘s market share is increasing year by year.

The Biscuit Manufacturing Process of the Commercial Biscuit Making Machine is very advanced, Biscuit Manufacturing Units only need to use one Biscuit Line to process and produce many different types of biscuits, we can also provide a complete market guidance plan to help the Biscuit Making Plant expand the market rapidly.

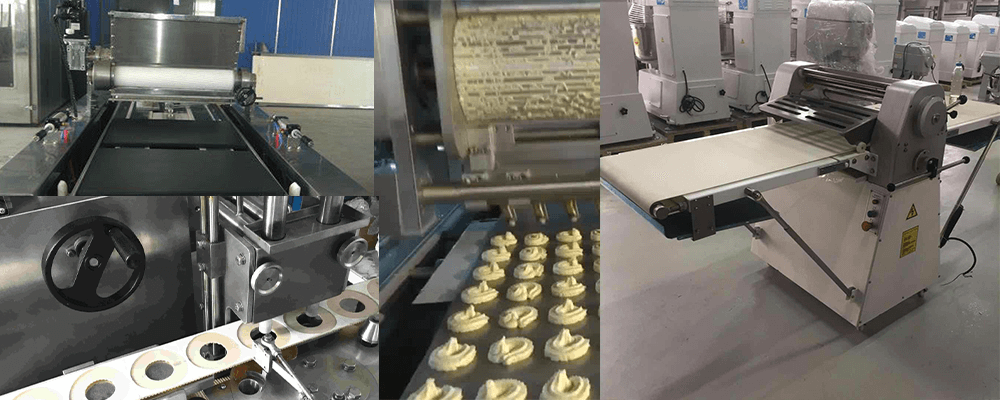

Biscuit Mechanical Drawing

What is the Finger biscuit production line?

Automatic Biscuit Production Line has a fully automated production method. It is composed of Biscuit Equipment such as dough mixer, conveyor, molding machine, oven, oil injection machine, cooling line and packaging machine . It can process and produce finger biscuits, cream biscuits, chocolate Various types of biscuits such as biscuits and sandwich biscuits can bring very high economic benefits to manufacturers.

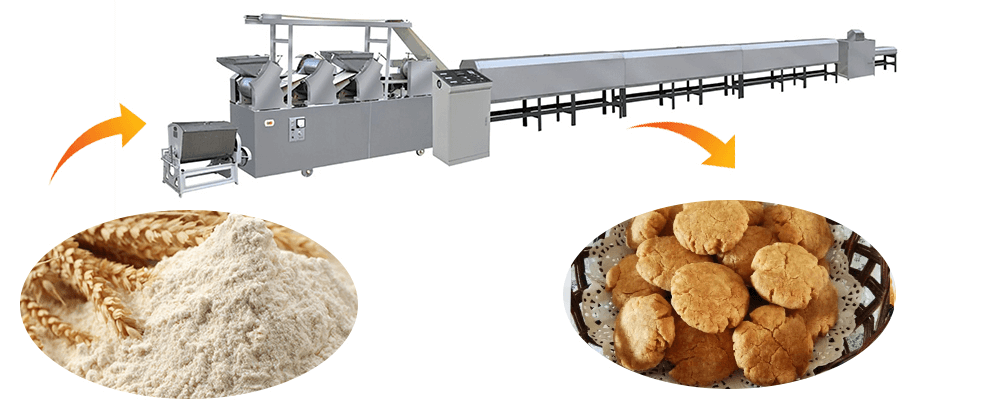

The process flow of Automatic Biscuit Production Line:

Kneading—forming—baking—oil spraying—cooling—finishing—packaging— finished product.

Cookie Flowchart

Basic composition of Commercial Biscuit Making Machine :

| Basic Composition of Biscuit Processing Line | |

|---|---|

| Noodle machine | A mixing machine that mixes flour with other ingredients and water into a dough. |

| Forming Machine | It is a dual-purpose forming machine for roll printing and roll cutting, which realizes automatic forming and automatic waste recycling. |

| oven | Using far-infrared heating, automatic temperature control, fast baking finger biscuits. |

| fuel injector | Spray oil on the surface of the baked finger biscuits to make the surface of the finger biscuits even in color and have a richer taste. |

| cooling line | Cool the oil-sprayed finger biscuits with adjustable speed. |

| Packing Machine | Fully automated packaging of finger biscuits. |

Different specifications of Automatic Biscuit Making Machine :

| There are specifications about the Cookie Making Machine | ||||

|---|---|---|---|---|

| model | power | Yield | Automatic Biscuit Making Machine Price | weight |

| 01 | 50kw | 50-150kg/h | Us $ 1,000.00 | 1t |

| 02 | 120kw | 100-200kg/h | Us $ 2,000.00 | 1.2t |

| 03 | 180kw | 200-350kg/h | Us$ 2 , 5 00.00 | 1.5t |

| 04 | 200kw | 300-450kg/h | Us $ 3,000.00 | 2t |

| 05 | 250kw | 300-500kg/h | Us$ 3 , 5 00.00 | 2.5t |

| Small Biscuit Making Machine in 2022, for more details, please contact our professional technical team of Biscuit Making Machine For Factory . | ||||

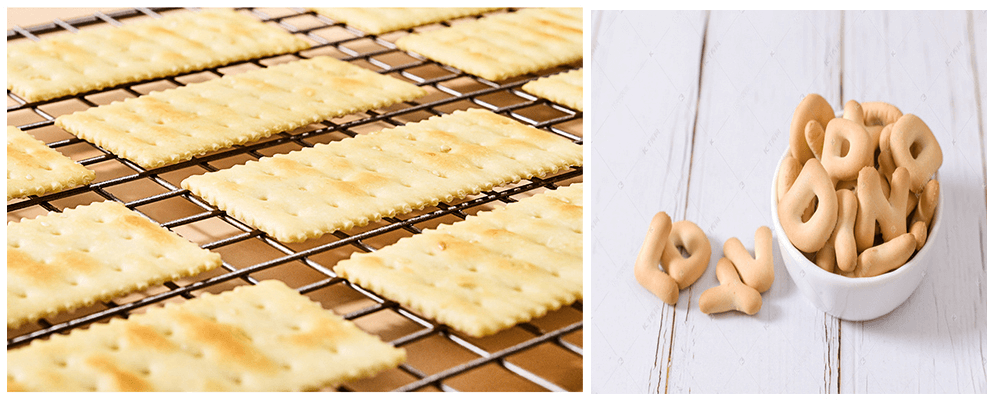

cookie chart

2021 Customer Order Finger biscuit production line Maker Form:

| Dealed Customer Have Plant Of Cookie Making Machine | |

|---|---|

| 1 | Thailand 500-600kg/h Stainless Steel Small Cookie Making Machine |

| 2 | 200-300kg/h Big Output Bakery Biscuit Making Machine In Singapore |

| 3 | Indonesia 1-2t/h High Productivity Automatic Biscuit Making Machine |

| 4 | Pakistan 700-800kg/h Multifunction Cookie Production Line |

| Dealed Customers Who Repurchase Of Small Biscuit Making Machine At 2021 | |

|---|---|

| 1 | France 800kg/h Easy Operation Industrial Biscuit Making Machine |

| 2 | Germany 500-600kg/h High Efficiency Biscuit Making Machine For Factory |

| 3 | 2-3t/h Ce Iso Biscuit Production Line For Italy |

| 4 | 3t/h Energy-saving B iscuit Manufacturing Equipment In Argentina |

1. What are the advantages of Biscuit Manufacturing Equipment?

1. The structure of each Biscuit Equipment is compact and the floor space is small, which can help the Automatic Biscuit Plant to reduce the investment cost.

2. Food grade stainless steel material, reliable quality and long service life.

3. Fully automated production method, high production efficiency.

4. The Biscuit Manufacturing Process is advanced. It only needs to change the mold to process and produce different types of biscuits. It is suitable for a variety of Biscuit Projects .

5. It runs smoothly and can realize 24h continuous production.

2. How to Verify Quality of Commercial Biscuit Making Machine

1. Biscuits are foaming : the temperature in the front area of the oven is too high, and the oven temperature should be controlled at this time ; the dough elasticity is too large, and the dough elasticity should be reduced at this time ; the agglomeration of the leavening agent has not been opened, and attention should be paid to the agglomeration at this time. The leavening agent is crushed before use .

2. The biscuits are not colored: the sugar content in the formula is too low, and the amount of invert sugar or Yi sugar should be increased at this time.

3. The taste of the biscuits is rough: the time for mixing the powder is insufficient or too long, and the maturity of the powder should be judged in time; the amount of oil and sugar in the formula is too small, and the amount of oil and sugar should be appropriately increased and an appropriate amount of phospholipids should be added.

4. The biscuits are fragile: the biscuits are overly swollen and too loose, so the amount of leavening agent should be reduced; the amount of starch and biscuit crumbs in the ingredients is too much, and the amount should be appropriately reduced.

3. What is our service?

1. Assist you in the layout of the biscuit factory, the selection of equipment, and the design of the Biscuit Making Process .

2. The relevant Biscuit System can be customized according to your specific needs.

3. Design a reasonable packaging and transportation plan for you, and dispatch technicians to install and debug it.

4. Offer you a discounted Automatic Biscuit Making Machine Price and provide the corresponding parts.

5. To provide you with 24-hour online consultation services.

Finger Biscuit Production Line Vido