LOYAL is a very well-known Biscuit Machinery Manufacturer . The Sakura Biscuit Production Line developed and produced by us has a high degree of automation, simple structure, compactness, large output and stable operation. It has many significant advantages. Many well-known Biscuit Making Plants have reached agreement with us. a good cooperative relationship.

Our Biscuit Making Machine For Factory has received a very high evaluation in the industry. At the same time, we will also provide a very complete after-sales service. When you buy our Automatic Biscuit Making Machine , we will track the order throughout the process and solve your problems. All problems that arise during the use of Biscuit Production Line .

What is Biscuit Manufacturing Equipment?

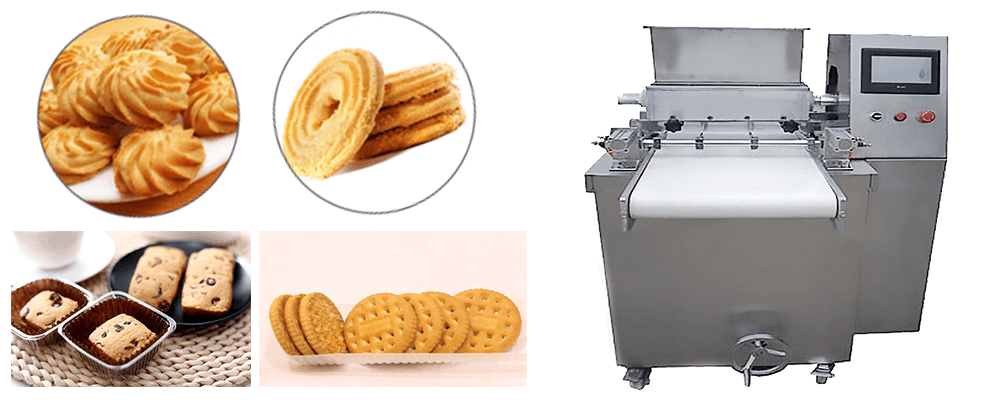

Automatic Biscuit Production Line is a new type of food machinery with automatic constant temperature, automatic baking, conveying, automatic oil injection, cooling and other functions, which can process and produce various types of biscuits, such as soda biscuits, wafer biscuits, and cookie biscuits etc., the Biscuit Making Process is advanced, and the biscuits produced are excellent in color, flavor and shape, and are favored by consumers.

The process flow of Biscuit Processing Line:

Kneading—forming—baking—oil spraying—cooling—finishing—packaging.

Key Features of Biscuit Line :

| Advantages of Commercial Biscuit Making Machine | |

|---|---|

| 1 | Fully automated production method, high degree of automation , stable operation and large output. |

| 2 | PLC control system, Biscuit Manufacturing Process requires no manual intervention, and the operation is simple and convenient. |

| 3 | Food grade stainless steel material, easy to clean, not easy to damage, long use time. |

| 4 | Energy saving, power saving and high efficiency , Biscuit Manufacturing Process is advanced, and the quality of processed biscuits is very high. |

| 5 | Commercial Biscuit Making Machine is versatile and can process many different types of biscuits. |

Specifications of Cookie Production Line :

| There are technical parameters about Biscuit System | ||||

|---|---|---|---|---|

| Model | 01 | 02 | 03 | 04 |

| Power | 60kw | 120kw | 180kw | 250kw |

| Yield | 100-200kg/h | 200-300kg/h | 250-350kg/h | 300-400kg/h |

| Machine weight | 1t | 1.5t | 2t | 2.5t |

| Biscuit Manufacturing Machine Price | Us$ 1 0,000.00 | Us$ 2 0,000.00 | Us$ 3 0,000.00 | Us$ 4 0,000.00 |

| Biscuit Making Machine For Factory in 2022, please contact our Automatic Biscuit Making Machine professional technical team for more details . | ||||

2021 Customer Order r Biscuit Production Line Maker Form:

| Dealed Customer Have Plant Of Cookie Production Line | |

|---|---|

| 1 | India 1-2t/h No Pollution Biscuit Manufacturing Equipment |

| 2 | Egypt 200kg/h No Noise Commercial Biscuit Making Machine |

| 3 | 800kg/h Multi-function Biscuit Processing Line For France |

| 4 | 1t/h Italy Customized Automatic Biscuit Production Line |

| Dealed Customers Who Repurchase Of Biscuit Line At 2021 | |

|---|---|

| 1 | Turkey 300-500kg/h Ce, Iso9001 Sakura Biscuit Production Line |

| 2 | Brazil 600-700kg/h 304 Stainless Steel Biscuit Making Machine For Factory |

| 3 | 400kg/h High Efficiency Biscuit Making Technology In Switzerland |

| 4 | 2t/h Saving Labor Biscuit Manufacturing Process In Netherlands |

1. What are the main components of the Sakura Biscuit Production Line ?

Cookie Production Line is composed of dough mixer, elevator (dump machine), feeder (laminator), noodle rolling machine, toughness (roll cutting and printing) forming machine, separator, bypass recycling machine, furnace feeding machine, Fully automatic production line composed of main Biscuit Equipment such as furnace conveyor (furnace net drive), tunnel oven (electric furnace or gas furnace), furnace peeling machine, oil injection machine, oil filter machine, cooling line, biscuit filling machine and so on .

Biscuit Making Plant

2. How Biscuit Making Machine For Factory Works

When carrying out the Biscuit Project , there are two main types of Biscuit Equipment , namely roll-printed biscuit formers and roll-cut biscuit formers . The roll-printed biscuit forming machine is to roll the dough mixed by the flour mixer into various shapes of biscuits. The roll-cut biscuit forming machine is to roll the reconciled dough according to a reasonable rolling ratio to form a dough, and then roll it into a green biscuit to produce some tough biscuit and ultra-thin biscuit.

3. Biscuit Line Maintenance Process

1. Regular cleaning : Automatic Biscuit Plant should clean the Cookie Production Line after each production to ensure that the sliding surfaces, lead screws, racks, gear boxes, oil holes, etc. are free from oil , some chips and debris , The dirt should be cleaned up .

2. Lubrication : Refuel or change oil on time, and lubricate the parts that are easy to wear in time.

3. Standard operation: comply with safe operation rules , regular inspection and precision inspection , eliminate unsafe factors in time , and improve the service life of Automatic Biscuit Production Line .

Sakura Biscuit Production Line Vido