We are a professional Biscuit Machine Manufacturer with many years of experience in Biscuit Maker Productionp, and we have been working with engineers who are experienced in Biscuit Machine Manufacturing Research Technology for decades. The market for Cookie Maker has been expanding. With Automatic Biscuit Making Machine as the main point of sale, we offer a wide range of recipes and molds for each customer to produce a variety of shapes and flavors of cookies.

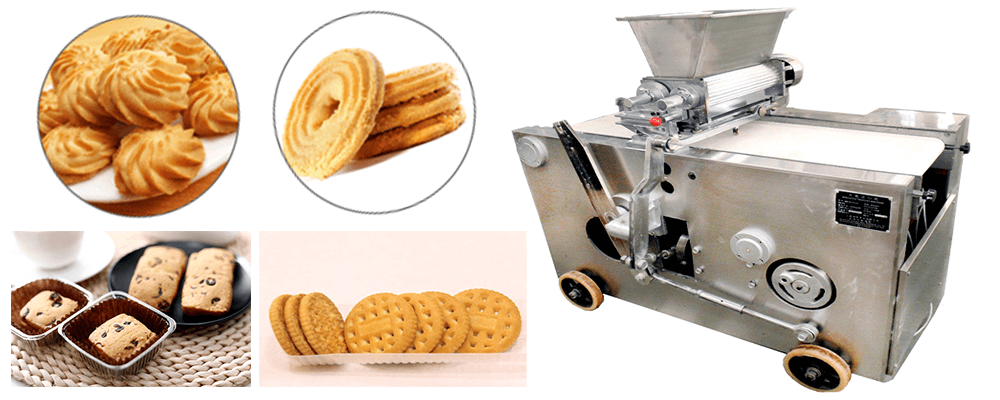

Cookie making machine diagram

Why are Bear Cookies famous?

1.Bear Biscuit is a kind of children’s cookie. In terms of appearance, it is different from the ordinary square or round cookies and is in the shape of a bear animal, which is cute and exciting.

2. Bear Biscuit Production Process formula has added alkaline substances, which can neutralize the stomach acid in the human stomach, reduce the stimulation of stomach acid on stomach mucosa, help appetite and eliminate food, regulate intestines, strengthen spleen and spleen, and nourish stomach and stomach.

3. In Bear Biscuits Manufacturing Process, the flour is enriched with copper, a trace element that stimulates the central nervous system and immune system and improves immunity.

4. In addition, the flour of Bear Cookies contains many carbohydrates, which can provide and store calories, regulate fat metabolism and provide dietary fiber.

Cookie Chart

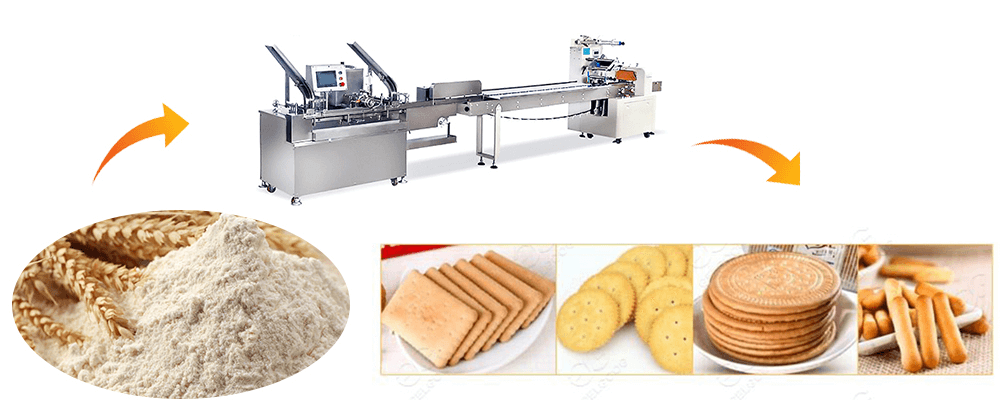

Advantages of Automatic Biscuit Production Line.

1. Biscuit Making Machine For Factory is highly automated, from feeding to calendering, molding, scrap recycling, drying, oil spraying, cooling, etc., is fully automated and completed at once, saving manual operation and cost.

2. Biscuit Manufacturing Equipment with automatic power off and alarm device, Biscuit Line equipment is safe and reliable, high practical performance.

3. Automatic Biscuit Production Line is composed of imported components and electrical appliances, with compact structure, high strength, and high production efficiency.

4. Biscuit Manufacturing Units can be adjusted for speed and humidity, with good energy-saving effect, and the Biscuit Making Plant is highly pushable in operation. Biscuit Machinery Diagram

What is the leading equipment of Biscuit Manufacturing Equipment?

| Main Equipment Of biscuit Production Line | |||||

|---|---|---|---|---|---|

| Main Equipment | Main Equipment Dimension(mm) | Power(KW) | Voltage(V) | Production Capacity | |

| Forming machine | 1704L×1040W×1750H | 7.5 | 380 | 250kg/h | |

| Roll-cutting cookie forming machine | 11100L×1400W×2000H | 16.3 | 380 | 600kg/h | |

| Roll-printing cookie forming machine | 2380L×1020W×1450H | 3 | 38 | 780kg/h | |

| Oil spraying machine | 2340L×1060W×1680H | 3.5 | 380 | 750~800kg/h | |

| Turning machine | 4000L×800W×1000H | 2.2 | 380 | 5.5m/min | |

| Cooling conveyor | 20000L×920W×1000H | 1.5 | 380 | 650kg/h | |

| Cookie finishing machine table | 8000L×1080W×1050H | 4.5 | 380 | 2-6m/min | |

| High speed pillow type multifunctional automatic packing machine | 4000L×950W×1450H | 2.5 | 220V/50HZ | 50-220 packs/min | |

How to make the dough in Biscuit Manufacturing Process?

| Biscuit Project type of dough modulation | ||

|---|---|---|

| Type | Point | Operation |

| Tough cookie | 1. The dough is made under the condition that the protein is fully hydrated. | 1. Add oil, sugar, milk, egg, and other auxiliary ingredients to the dough by heating water or hot syrup and stirring it in the mixer, then add flour to make it. |

| 2. The oil and sugar content in the ingredients is low, and the gluten can easily absorb water and swell and moisten, so you can add a quantity of hot water to raise the dough’s temperature when modulating. | 2. Improver should be added after ten minutes of dough modulation. | |

| 3. The dough tends to be relaxed under a long time mechanical stretching of the dough mixing machine, so the modulation time of tough dough should belong to prevent it from losing its tenderness. | 3. The modulation process of adding puffing agent and flavoring, respectively, continues to modulate before and after about 40 minutes or more. | |

| Shortbread cookie | 1. The Rolling of shortbread dough is to get a flat dough sheet, but not for a long time. Otherwise, the dough sheet will be challenging and shrink. | 1. Put all the ingredients except the flour into the unique mixer and mix slowly for a few minutes. |

| 2. The dough contains more oil and sugar, the dough sheet is soft and easy to break, and it is not possible to roll it many times, usually with 3 to 7 one-way reciprocal rolls or one-time one-way rolls. | 2. Sometimes, it is necessary to add monoglycerides or phospholipids in the recipe to help form a uniform emulsification system. | |

| 3. The pastry dough should not be left to rest for a long time before rolling, and the dough sheet after rolling should be thicker than the tough dough, with a thickness of 2 cm. | 3. Add the flour to the well-mixed ingredients and mix the original and auxiliary ingredients evenly. | |

Biscuit picture

2021 Automatic Biscuit Making Machine Customer Deal Case:

| Customer cases of Commercial Biscuit Making Machine in 2021 | |

|---|---|

| 1 | South Africa 600kg/h good quality Biscuit Making Machine |

| 2 | Russia 600-700kg/h Full Automatic Biscuit Manufacturing Equipment |

| 3 | Germany 1-2t/h Biscuit Making Machine |

| 4 | Thailand 700kg/h Professional Automatic Cookie Making Machine |

| 5 | France 1t/h Baby Cookie Making Machine |

| 2021 Customer Repurchase Case of Industrial Biscuit Making Machine | |

|---|---|

| 1 | 400kg/h high Quality Industrial Small Cookie Making Machine in Indonesia |

| 2 | 500-600kg/h Mini Biscuit Making Machine in Germany |

| 3 | 800kg/h Best Price Biscuit Making Equipment for Singapore |

Our company has a broad overseas market, frequent foreign exchange of Biscuit Machine Manufacturing Technology, more robust professionalism, and a first-class Biscuit Machine Manufacturing team. If you are interested in Cookie Production Line, please feel free to contact our Biscuit Making Machine team; we will provide you with Biscuit Manufacturing Process suggestions according to your specific situation; we sincerely welcome your cooperation.

1. What is the cause of Biscuits Finished blistering?

1.The temperature of the front part of the oven in the Automatic Biscuit Production Line is too high, especially the temperature of the top fire is too high.

2. Biscuit Project’s dough elasticity is too large; when baking gluten blocking the gas channel is not easy to disperse, so the surface bubbles should reduce the elasticity of the dough and use a mold with more pins.

3. puffing agent lumps are not opened; care should be taken to crush the lumped puffing agent before use.

4. Biscuit Line roller rolling too much flour on the dough belt, should try to avoid sprinkling flour or less flour.

2. Why will shrinkage and deformation be in Biscuit Production Process?

1. Biscuit Processing Line is too tight in the process of belt calendering and delivery. The belt should be adjusted, especially in the second and third pair of rolls, to have a certain degree of sagging, and the canvas belt should be kept in a flaccid state when the belt is delivered.

2. If the dough of the Biscuit Project is too elastic, increase the amount of dough improver or increase the mixing time, and add the right amount of starch to dilute the amount of gluten.

3. Automatic Biscuit Plant’s dough belt is always calendered in the same direction, which causes uneven tension of the dough belt. The dough belt should be continuously changed to 90° direction when rolling and folding.

3. What is the future of the Biscuit Industry?

A cookie is the main product of casual food, especially in recent years, the improvement of the living standard of our people, the market of casual food has further expanded, the types of cookies are also enriched with the changing consumers, thin and crispy cookies, cookies, sandwich cookies, wafer cookies, etc., the development prospect of Biscuits Market is still broad.

But most consumers choose cookie products are not only to provide energy, such as Oreo cookies novelty advertising slogan on the reach children’s favorite, won a considerable profit, Biscuit Products and brand value is still climbing through this, has a unique Cookie Brand symbol.

Therefore, it can be seen that the essence of the Biscuit Project’s success requires market segmentation, accurate positioning of consumer groups, and the creation of their cookie brand symbols and memories, thus being accepted by consumers.

Bear Biscuit Production Line Vido