This Angola customer contacted us by browsing our website, he is from Angola and wanted to produce the popular Marie biscuits, which are round sweet biscuits of British origin, similar to rich tea biscuits. Ingredients include flour, sugar, vegetable oil and vanilla flavor. The customer currently has a 300kg/h Marie biscuit production line, which is a well-known local biscuit manufacturing factory, producing all kinds of biscuits, pastries, etc. Our company has nearly 10 years of experience in exporting to the Angolan market. Due to the high sales of biscuits in Angola, he wanted to expand production and buy another 500kgh production line. Customers are more concerned about the full automation of the production line, so we configure a fully automated 500kg/h Commercial Marie biscuit production line for him.

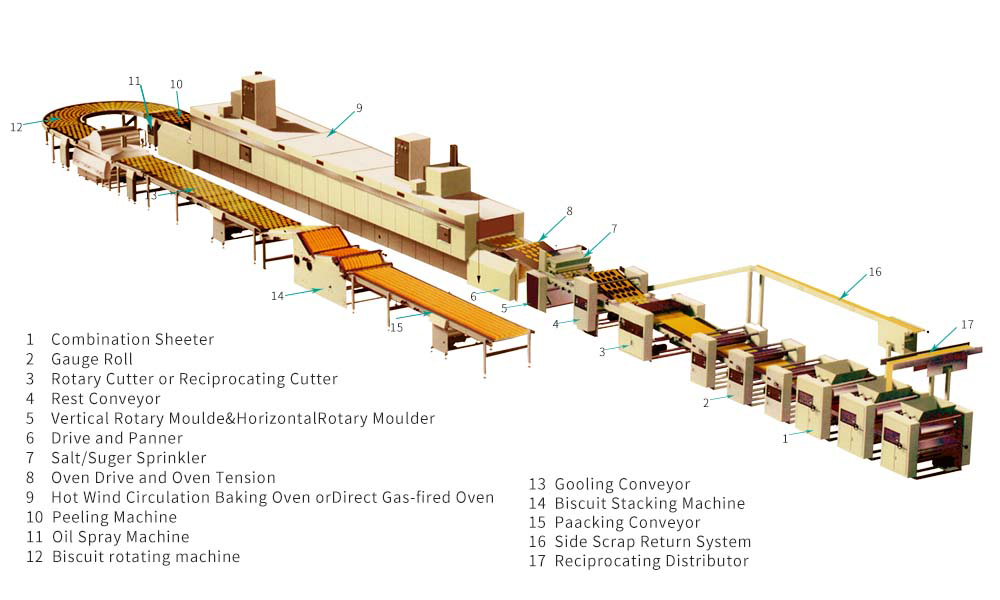

After understanding the technological process and steps of the Marie biscuits that the customer wants to produce, we provide him with the following machines. In Angola, gas is more economical to use for a long time, so we have equipped him with a gas-heated oven. The length of the customer’s factory is not enough, so we configure a 180°turning machine for him.

How Marie Biscuits Are Made In Factory

|

500kg/h Commercial Marie Biscuit Production Line Equipment List |

||

|

S/N |

Item |

Quantity |

|

1 |

Flour Mixer |

1 Set |

|

2 |

Dough Cutting Machine |

1 Set |

|

3 |

Dough Conveyor |

1 Set |

|

4 |

Roll Cut Biscuit Form Machine |

1 Set |

|

5 |

Inlet Oven Machine |

1 Set |

|

6 |

Tunnel Oven(Gas Heating Method) |

1 Set |

|

7 |

Outlet Oven Machine |

1 Set |

|

8 |

Oil Sprayer |

1 Set |

|

9 |

180° Turning Machine |

1 Set |

|

10 |

Net Belt Cooling Conveyor |

1 Set |

|

11 |

Biscuit Stacking Machine |

1 Set |

|

12 |

Packing Machine |

1 Set |

According to the Angola customer’s factory size, our engineer designed the layout for him.

According to the Marie biscuits the Angola customer wants to produce, we provide him with a recipe table.

|

Formula Of Biscuit Processing By 500kg/h Commercial Marie Biscuit Production Line |

|

|

Biscuit Process Ingredient |

Biscuit Process Proportion |

|

Flour: |

25kg |

|

Sugar: |

6kg |

|

Palm oil: |

6kg |

|

Butter: |

0.5kg |

|

Water: |

2.5kg |

|

Syrup: |

300g |

|

Ammonium bicarbonate: |

100g |

|

Baking soda: |

100g |

|

Salt: |

150g |

|

Starch: |

1kg |

500kg/h Biscuit Production Line Site Pictures

The customer is more concerned about the brand of the motor, he chooses the ABB motor, the following list is the parameter table of the ABB motor.

|

Specifications Of 500kg/h Commercial Marie Biscuit Production Line For Business Motor |

|

|

Attribute |

Value |

|

Power Rating |

0.18 KW |

|

Efficiency Class |

IE2 |

|

AC Motor Type |

Induction |

|

Supply Voltage |

415 V ac |

|

Phase |

3 |

|

Output Speed |

1380 rpm @ 380 V |

|

Number of Poles |

4 |

|

Mounting Type |

Foot |

|

Rotation |

Reversible |

|

Maximum Output Torque |

1.25 Nm |

What Is Advantages Of 500kg/h Commercial Marie Biscuit Production Line?

|

Features And Functions Of 500kg/h Commercial Marie Biscuit Production Line |

|

|

No. |

Features And Functions |

|

1 |

Made various shapes of biscuit according to the needs of users, such as: spherical, square, bar, etc. |

|

2 |

According to the needs of users, we can produce biscuit of different sizes and different shades of patterns. |

|

3 |

Fully automatic and improving production efficiency. |

|

4 |

Continuous production, no material loss and save cost. |

|

5 |

No noise, no pollution. Save energy and labor |

After the customer confirms the order and receives the deposit, we completed the production within 30 working days and test the machine in the factory. After the customer pays the balance, we shipped the goods to Angola immediately.