Loyal fully automatic biscuit making machine produces biscuits mainly made of wheat flour with sugar, fats, eggs, dairy, and other auxiliary ingredients. Depending on the biscuit recipe and the biscuit production process, cookies can be divided into two categories: tough cookies and crispy cookies.

The compact structure of the automatic biscuit making machine, the opening and closing of the mold, the operation, the oiling of the mold, the scrap taking out the machinery, the shaping, including the baking to the packaging of the whole process can be automated through PLC control.

Relative to the food processing industry, the Biscuit Making Machine industry is still considered a nascent industry because since its birth to constitute an industry only 20 years. Therefore its development relative to other food industries is relatively leading.

The Biscuit Making Machine can produce all kinds of toughness and crispy Biscuit . This series of the biscuit making plant can be combined at will according to the user’s site requirements and the requirements of the Biscuit process, and by changing the mold and process formula, can produce various kinds of high-grade Biscuit famous in the market, such as cream Biscuit, sandwich cookies, soda cookies, animal cookies, vegetable cookies, etc…

With the development of Biscuit processing technology, Biscuit have become one of the leading indispensable food for people.

Features of biscuit making machine

1. Theindustrial biscuit making machine is easy to operate.

2.One-stop cookie production solution, no need for multiple cookie machines to debug each other.

3. Most parts of the biscuit making plant are made of stainless steel, resistant to wear and tear, good cleaning

4.manufacturer biscuit manufacturing unit has a wide range of applications and can produce hundreds of cookies to meet the needs of all biscuit making plant

5.loyal biscuit machine has its own cookie industry service, which will provide users with the latest cookie making process, cookie process PPT and video on a regular basis.

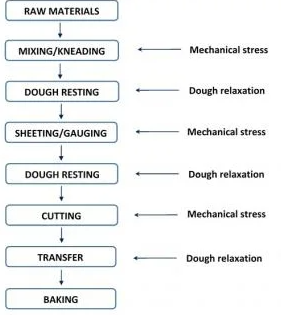

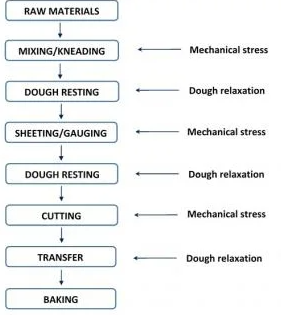

biscuit manufacturing process flow chart:

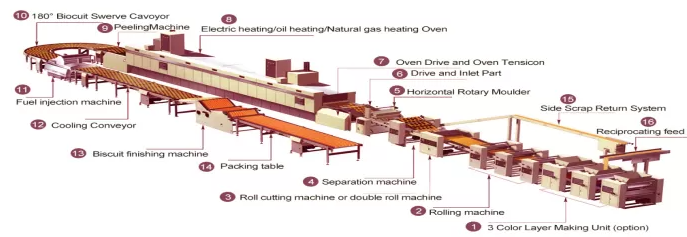

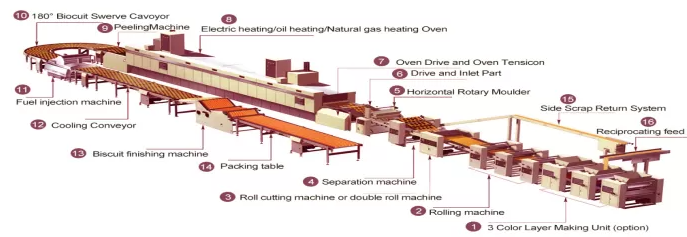

biscuit production process diagram

Biscuit Manufacturing Process Flow

The fully automatic biscuit making machine includes one dough mixer, one molding head, a oven, a cooling line, one distribution box, two machine-belt molds and a total length of 12 meters. The full power is 33KW, the volume is 8 cubic meters, and the weight is about 1 ton. The output is 60 to 70 kg per hour.

Pretreatment Of Raw Materials – Dough Preparation – Rolling Dough Sheet – Pressing Into Cake Base – Baking – Oil Spraying – Cooling

| Biscuit Manufacturing Unit |

Rotary Cutter |

| Horizontal Dough Mixer |

Rotary Moulder |

| Three rolls Pre Sheeter |

Tunnel Oven |

| Laminator for automatic biscuit making plant |

Cooling Conveyor and Stacker Machine |

| Gauge Roller for biscuit making plant |

Biscuit Packing Machine |

Biscuit Making Process And Biscuit Recipe For Fully Automatic Biscuit Making Machine

The primary raw material of biscuit is flour, in addition to sugar, starch, grease, dairy products, eggs, flavoring, bulking agents, and other auxiliary ingredients. the above raw materials and extra components are modulated into the dough by the biscuit dough mixing machine, then rolled into dough sheets by the rolling machine, pressed into biscuit blanks by the biscuit molding machine, and finally baked by the oven, and become crispy and delicious biscuit after cooling. sweet biscuit can be divided into two categories, namely tough biscuit and shortbread biscuit. whether it is a tough biscuit or shortbread biscuit, the recipe, feeding order, and operation method are different, but the basic process is similar.

1. Biscuit Raw and auxiliary materials pretreatment for small scale biscuit manufacturing unit

All the raw and auxiliary materials of this product will be led into the biscuit process plant, sieved and ready for use.

2. the dough modulation for Biscuit Making Process

This is the key step, in general, the biscuit manufacturing process, the choice of raw materials account for 50% of the factors to determine whether the success. Secondly, the operation of flour blending accounts for 25%, baking accounts for 20%, while other rolling and forming accounts for only 5%. Because the dough modulation not only determines the flavor, taste, appearance, form and color of the finished product, but also directly relates to whether the next process can be carried out normally.

(The fully automatic biscuit making machine has perfectly automated the step of dough adjustment, significantly reducing the time and waste in the biscuit production process.)

2.1、Making of crispy dough for Biscuits Manufacturing Unit

Puffy or sweet puffy dough is commonly known as cold flour, this dough requires a greater degree of plasticity and limited viscoelasticity, and the finished product is puffy biscuit.

Since the shape of this kind of biscuit is stamped or rolled into relief off mottled patterns with impressions, it requires not only a certain degree of bonding when the dough is rolled into dough for continuous machine operation and non-stick rollers and models, but also a clear relief-type pattern for the finished product.

The formation of gluten will make the dough elasticity and strength increases, plasticity decreases, causing toughness and shrinkage deformation of the formed biscuit, and because the gluten formed film will make the surface rise in the baking process to initiate bubbles.

(Loyal automatic biscuit making plant has automated the step of making crispy dough, which can be done with a simple setup)

2.2, the characteristics of tough dough for biscuit manufacturing unit

Compared with crisp, tough dough has the following characteristics.

A, sugar and oil is relatively low, the gluten is easy to form when mixing flour.

B, requires a smaller volume mass of the product, the taste of crispy, that is, the expansion rate should be large, and the organization is a detailed laminar structure.

C, due to the cost of the trait requirements, the processing process is different from the crispness, such as: to be calendered by multiple operations, the use of punch molding.

According to the above characteristics, tough dough characteristics should be: the gluten of the dough is not only fully formed, to have strong extensibility, plasticity, moderate bonding and soft, glossy nature, the strength and elasticity can not be too large.

3, the modulation of soda biscuit

In the making of biscuit , sometimes, in order to improve the effect of fermentation, a part of flour and water plus yeast and other additives are first mixed into dough (called medium seed) for a longer fermentation.

Then the remaining flour and auxiliary ingredients are added for formal mixing. Finally, fermentation, shaping and molasses are carried out. This method of mid-seed fermentation is mostly used in soda biscuit in order to increase the fermentation potential of the dough by allowing the yeast to get fully multiplied in the dough through a longer resting time.

While fermenting, the metabolites of wild fermentation: lactic acid, acetic acid and alcohol produced by yeast fermentation, dissolve and denature the dough tendons. The carbon dioxide produced during fermentation causes the dough to expand in volume, while leaving the gluten network in an elongated state.

Loyal soda biscuit making equipment already includes this process for automated control

Industrial automatic biscuit making machine for sale at LOYAL in 2021 :

| 2021 Transaction case customers with Biscuit Making Equipment |

| 1 |

Customized Center Filled Forming Fully Automatic Biscuit Making Machine for Sale In Nigeria |

| 2 |

Stainless steel small mini automatic cookies making machine send to kolkata |

| 3 |

High Efficiency Salt Spreading Machine Thin Biscuit Sesame Sprinkler Making Machine for Sale in delhi |

| 4 |

Automatic chocolate or jam depositing biscuit making machine for Sale in coimbatore |

| 5 |

Factory Tray Type Rotary Moulder Cookie Forming Biscuit Making Machine sold to south africa |

| 6 |

Small PLC Cookie Macaron Making Machine Cookie Biscuit Machine for Indonesia |

| 7 |

Biscuit Manufacturing Plant Biscuit Processing Line for Sale in Ethiopia |

| 8 |

Wafer Biscuit Production Line Making Machine with Packing full Line sold to Mexico |

| 9 |

Small Scale Cookies Bakery Equipment 100kg/H Filling for Chile |

| 10 |

150kg Per H Industrial Biscuits Making Machine for Nigeria |

Top 13 Classic Questions About industrial biscuit making machine

1.What is the development prospect of the biscuit market?

2.Which machines are used in making biscuits?

3.What is the process of making biscuits?

4.What type of flour is used to make biscuits?

5.how to operate the industrial biscuit making machine and precautions

6.What are the 4 steps in the biscuit mixing method?

7.What are the two most important steps in biscuit making?

8.What are the raw materials for biscuit?

9.What types of biscuits are there?

10.Benefits of cookie Making Machine

11.How much Biscuit Production Line Cost

12.how do you prevent cookies from cracking?

1.What is the development prospect of the biscuit market?

Today, with the rapid development of basic science and new technologies, the international biscuit industry, which has a history of rise and fall for more than 100 years, is highly developed in terms of biscuit color varieties, biscuit rolling machines and linkage, and in some countries, computers have been used to manage fully automatic biscuit making machine for biscuit industrial production.

The countries where the international biscuit industry is more developed include the United Kingdom, the United States, former West Germany, Japan, and other countries. Some of the most famous cookie factories globally include the British Biscuit Company, the National Biscuit Company of the United States, the Meiji Fruit Company of Japan, and the Kadason Biscuit Company of Denmark. The variety of cookies has grown to thousands so far.And the cost of biscuit making machine is getting lower and lower

2.Which machines are used in making biscuits?

Some of the biscuit making machines that make up the biscuit production line include baking and handling machines, soft dough forming machines, mixing and dough feed equipment, sheet forming and cutting equipment, biscuit sandwiching and many more.

Biscuit Manufacturing Equipment Details:

2.1 Mixing machine for small cookie making machine

Mixing machine is a machine that mixes flour and water or other ingredients into dough. It is widely used for making various kinds of pastry, cookie, bread, steamed bun and other doughs.

2.2 Forming machine- Automatic cookie production line / soda cookie production equipment / crispy tough cookie food machine / cookie machine

Roll printing (crispness): put the mixed flour into this machine, and it can become cookie embryo by roll printing, and make various cookies in the oven.

Roll cutting (toughness): put the mixed dough into this machine, through three rollers to press the skin, and then through the roll cutting mold once roll cutting into cookie embryo, into the oven, bake the most tough cookie.

2.3 Electric baking oven for automatic biscuit making plant

The use of electric or gas heating, temperature zone control, each temperature zone temperature can be set, temperature uniformity within the temperature zone, the use of high-quality insulation materials, good adiabatic performance, high thermal efficiency, the inner plate of the furnace sprayed silver powder with silicon. Temperature control system, automatic temperature control and constant temperature, flexible operation, high safety performance, suitable for baking all kinds of cookies. Baking ovens to increase the width and length according to the output.

2.4 Oil spraying machine – toughness shortbread cookie production line / roller cutting roller printing cookie processing machinery

Spraying oil on the surface of the cookies coming out of the baking oven makes the color, aroma and taste of the cookies more distinctive and improves the grade of the cookies.

2.5 Turning machine:turn the opposite direction 90 degrees and 180 degrees, can be customized according to the requirements. Save the space of the site with turning way.

2.6 Cooling machine for biscuit making automatic machine

This equipment is fully cooled before the cookies are transferred to the packing machine to ensure the quality and extend the shelf life of the cookies after packing.

2.7 Biscuit sorting machine- cookie production line Small cookie machine

It is used to arrange the cooled cookies neatly in rows to facilitate the next step.

2.8 Biscuit Sandwich Machine for industrial cookie making machine

Used for cookie sandwiching equipment, two plus one cookies, three plus two cookies, can be customized. Sandwich material: cream, fruit jam, etc.

2.9 Packing machine for small biscuit making machine

Used for cookie packing, pillow packing machine

| List Equipment Of Biscuit Making Machine Manufacturing Process |

| Name |

Biscuit Machine Technical Parameter |

| Dough Mixer Machine |

Motor power: 4.5kw |

|

Tipping bucket power: 0.95kw |

| Voltage: 380v/50hz |

| Size: 1350*840*1350mm |

| Mixing time: 10-15min |

| Material: stainless steel hopper, frame A3 carbon steel |

| Tough Biscuit Molder |

Power: 5.5kw |

| Dimensions: 4700*1050*1700mm |

| Production capacity: 150-200kgh |

| Voltage: 380v/50hz |

| Weight: 2700kg |

| Material: shell stainless steel, frame A3 carbon steel |

| Crisp Biscuit Molder |

Power: 2.2kw |

| Dimensions: 1800*1000*1250mm |

| Production capacity: 150-200kgh |

| Roller diameter: 248 |

| Weight: 500kg |

| Tunnel Oven |

Heating method: Electricity |

| Power: 100-120kw |

| Size 20000*1000*1300mm |

| Number of knots: 5 knots (normally 4 meters equals 1 knot) |

| Baking capacity: 150-200kg/h |

| Weight: 8000kg |

| Biscuit Sprayer |

Power: 2.2kw |

| Dimensions: 1800*1000*1850mm |

| Weight: 500kg |

| Material: shell stainless steel, frame A3 carbon steel |

| Cooling Conveyor Belt |

Power: 1.1kw |

| Size: 10000*700*800mm |

| Weight: 600kg |

| Material: stainless steel |

| Conveying method: mesh belt |

3.What is the process of making biscuits?

The biscuit making machine for factory production process:

Pretreatment Of Raw Materials – Dough Preparation – Rolling Dough Sheet – Pressing Into Cake Base – Baking – Oil Spraying – Cooling

4.What type of flour is used to make biscuits?

Low gluten flour is generally used for cookies because it is lower in protein than other flour, making the cookies fluffy and tasty. However, if you want to make thin and crispy soda crackers, you can also use high gluten flour for better shaping.

If you use a loyal fully automatic biscuit making machine, you can produce delicious cookies regardless of the type of flour.

5.how to operate the industrial biscuit making machine and precautions

Users should read the instruction manual carefully before use, understand the operation method and precautions of the small cookie making machine, and strictly follow the instructions to provide the most fundamental guarantee for the safe production of cookies.

Do not suddenly unplug the power during the operation of the small scale biscuit making machine, and do not frequently power off and on, which is very detrimental to the small biscuit making machine.

After use to clean up the residue and adhesion in time to prevent residue curing deposits, later cleaning up more complex, long-term accumulation of residue not only looks unattractive but also to the automatic biscuit making machine damage.

6.What are the 2 steps in the biscuit mixing method?

1 :Biscuit Raw and auxiliary materials pretreatment

A.Pre-treatment of flour.

B.Pretreatment of sugar.

C.Pretreatment of fats and oils.

D.Pretreatment of dairy and egg products.

E.Puffing agent, and salt pretreatment.

2:Mixing according to the ratio of raw materials according to different types of cookies, and adding additives at the same time

7. What are the two most important steps in biscuit making?

The first is to coat the flour in fat helping to reduce gluten development.

The second is to distribute little pieces of solid fat throughout the dough which will melt in the oven creating little pockets of flakiness.

8.What are the raw materials for biscuit?

The primary raw material of biscuits is wheat flour, and then add sugar, fat, egg, dairy, and other auxiliary ingredients. Depending on the biscuit recipe and the biscuit production process, sweet biscuits can be divided into two categories: tough biscuit and shortbread biscuit.

Tough cookies are characterized by a concave mold shape and a pinhole surface. The product’s surface is flat and smooth, and the cross-sectional structure is layered, with a crunchy feeling when chewed, chewy and crunchy as its unique characteristics. A tough biscuit’s sugar and fat ratio are lower than a crispy biscuit. Generally, the amount of sugar used is less than 30%, and the oil used is less than 20%. An automatic biscuit making plant is suitable for the production of tough biscuits.

Shortbread biscuits are characterized by a convex mold shape, apparent patterns, and fine structure, 14% to 30% of flour. Some sweet and sparse unique products, oil can be as high as about 50%. Shortbread biscuit is suitable for production by fully automatic biscuit making machine.

9.What types of biscuits are there?

| Classification Of Cookies According To The Ratio Of Raw Materials |

| Types of Biscuit |

Oil to sugar ratio |

Oil-sugar-to-flour ratio |

Biscuit Name |

Cookie production machine |

| Coarse Biscuit |

0:10 |

1:05 |

salt biscuit,caramel biscuit |

Biscuit-300- Biscuit Manufacturing Equipment |

| Tough Biscuit |

1:2.5 |

1:2.5 |

caramel biscuit,butter biscuit |

Biscuit-400 – Industrial Cookie Making Machine |

| Crisp Biscuit |

1:2 |

1:2 |

Sandwich Biscuit,cone biscuit |

Biscuit-800 – Biscuit Making Equipment |

10. Benefits of cookie Making Machine

1.All kinds of machines in the automatic cookie production line are equipped with frequency conversion speed control, and all kinds of machines cooperate tacitly to truly realize automation.

2.Cookie forming machine with frequency-controlled linkage, easy and quick operation

3.It can produce a wide variety of products and change the mold to produce a variety of shapes of cookies.

11. How much Biscuit Making Machine Cost

| 2021 Price for The Industrial Biscuit Making Machine |

| Biscuit Making Machine Model |

Biscuit-300 |

Biscuit-400 |

Biscuit-500 |

Biscuit-800 |

Biscuit-1000 |

| Whole Line Weight(Kg) |

22000 |

30000 |

37000 |

47000 |

57000 |

| Biccuit Line Price |

Us$31,000.00 |

Us$43,000.00 |

Us$56,000.00 |

Us$69,000.00 |

Us$72,000.00 |

| Capacity(Kgs/H) |

450-600 |

650-800 |

850-1000 |

1050-1200 |

| Total Power(Kw) Electric Baking Type |

245kw |

365kw |

520kw |

677kw |

12.how do you prevent cookies from cracking?

In cookie production line application, we often encounter the problem of cookie cracking, and customarily put the cookie cracking caused by external pressure or impact, this cracking is generally caused by human factors, mechanical factors and other external reasons. The cracking of cookie due to rapid cooling and unbalanced stress inside the cookie that exceeds the strength limit of the cookie is called natural cracking, which is mostly caused by the internal factors of the cookie and has more influencing factors.

Generally speaking, abnormal cracking can be reduced or solved by strengthening management, improving packaging and other measures, but the handling of natural cracking is more complicated, which has been a big problem in the cookie industry and is one of the reasons for the decline in economic efficiency of some biscuit making plant .

Factors influencing cookie cracking:

1. Cooling environment temperature

2.Cooling environment temperature

3.Grease dosage

4.Amount of sugar

5.Design of mould