As a professional Automatic Biscuit Machine Manufacturer, we are committed to providing our customers a complete range of services. Cookie food technology engineers have built our Biscuit Making Equipment with many years of experience.

Biscuit Production Line consists of a cookie forming machine, baking oven, spraying machine, bending machine, cooling line, cookie finishing machine, sandwiching machine, packing table, etc. This Fully Automated Biscuit Production Line model is highly automated, Biscuit Manufacturing This Fully Automated Production Line model is highly automatic, Biscuit Manufacturing Equipment is reliable, compact, and precise, and we will give you reasonable prices and Biscuit Equipment models to choose from.

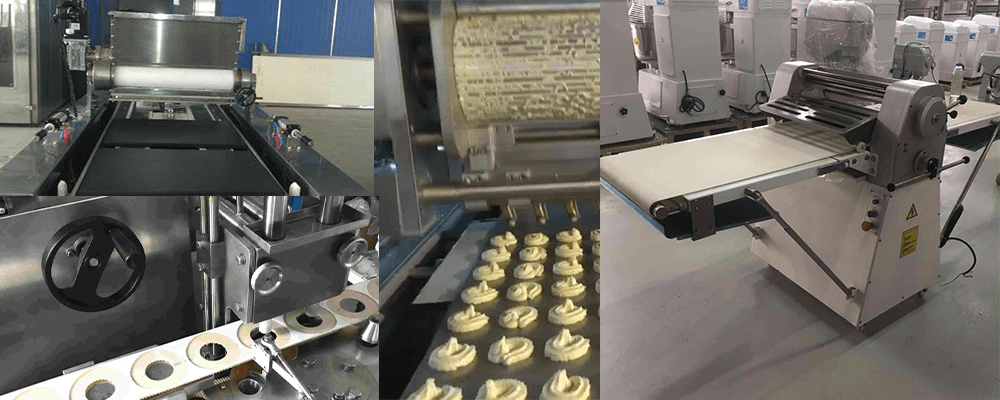

Biscuit Machine Diagram

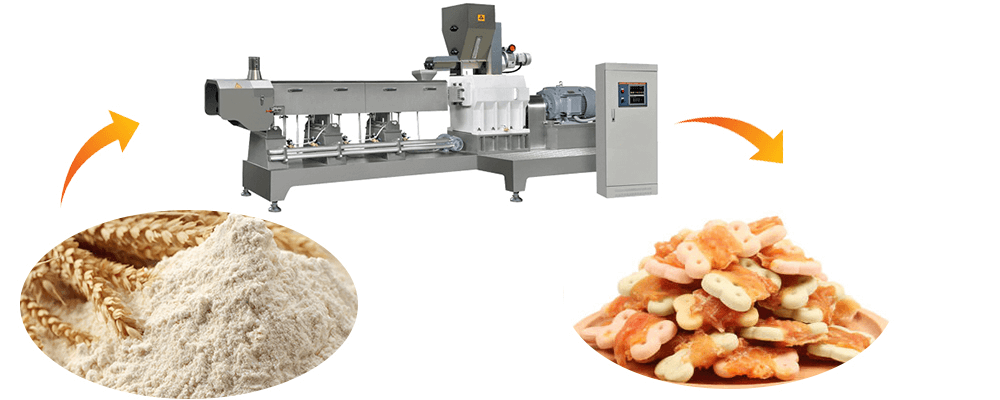

The Biscuit Manufacturing Process uses cereal flour as the main ingredient, with sugar, fat, protein, and dairy. Therefore, we provide various cookie molds and recipes for Automatic Biscuit Making Machine to produce multiple cookies such as cream, sandwiches, soda, and vegetable cookies.

Biscuit Making Machine For Factory advantages:

1. Automatic Biscuit Production Line realizes true automation, and each Biscuit Making Equipment works well with each other, reducing the tedious intermediate steps and manual operation.

2. Biscuit Production Equipment frequency control, easy to operate by staff.

3. The temperature control system in the Biscuit System has energy-saving technology. The oven is a tunnel-type electric oven with energy-saving quartz electric heaters, which can achieve rapid temperature rise quickly.

4. Each Automatic Biscuit Plant is fully equipped to produce various flavors and types of cookies.

Cookie machinery diagram

Small Biscuit Machine production method.

| Cookie Types | Shortbread cookies | Tough cookie |

| Flour(kg) | Low gluten Flour kg | Flour 25kg |

| Water/sugar(kg) | 2.5kg ,7.5kg | 3kg ,7.5kg |

| Dissolve water and sugar by heating | ||

| Sugar thin & white sugar/edible oil mix(kg) | Sugar dilution 2.5kg, white sugar 2.5kg, total 5kg | Sugar dilution 2.5kg, cooking oil 2.5kg, total 5kg |

| Citric acid(g) | 10g | 10g |

| Heat it slowly for 10min, then put in the following ingredients | ||

| Cookie relaxing agent / baking soda /ammonium bicarbonate/ sodium pyrosulfite(g) | 20g ,100g ,150g, 20g | 20g ,200g ,350g ,20g |

| Edible oil(kg)/Salt(g) | Edible oil6kg | Salt 150g |

| Mix the above ingredients for 15min | ||

| Put the first 4 columns of ingredients into the flour, and stir the flour in the order of 1min turn down and 1min turn up, about 10-15min | ||

| Let stand for 30-45min | ||

| Put the mixed ingredients into Bakery Biscuit Making Machine. | ||

Bakery Biscuit Making Machine Technical Parameters

Bakery Biscuit Making Machine Technical Parameters

| Model | Dimension(mm) | Total installed capacity(KW) | Baking temperature(℃) | Production capacity(kg/h) | Machine weight(T) |

| 225 | L18000×W600×H1500 | 30 | 200-300 | 60 | 1.5 |

| 280 | L28000×W800×H1500 | 60 | 200-300 | 150 | 2 |

| 400 | L48000×W1000×H1500 | 140 | 200-300 | 300 | 3 |

| 600 | L76000×W1200×H1750 | 220 | 200-300 | 600 | 4.5 |

| 1000 | L103000×W1850×H2450 | 340 | 200-300 | 1200 | 7 |

| Raw and auxiliary materials pretreatment → dough modulation → rolling → forming → cooling → finishing → packaging → finished product | |||||

| This is our updated Industrial Biscuit Making Machine list in stock for 2022. If you need to verify or correct it, don’t hesitate to contact us. | |||||

Biscuits Picture

2021 Customer Order Biscuit Production Line Maker Form:

| Dealed Customer Have Plant Of Industrial Biscuit Making Machine | |

|---|---|

| 1 | 400kg/h Automatic Electric Industrial Small Cookie Making Machine for India |

| 2 | Pakistan 400-500kg/h China Ce Manufactory Mini Biscuit Making Machine |

| 3 | Japan 1t/h Full Automatic Biscuit Manufacturing Equipment |

| 4 | 700kg/h Professional Cookie Making Machine For Sale in America |

| Dealed Customers Who Repurchase Of Automatic Biscuit Making Machine At 2021 | |

|---|---|

| 1 | 500kg/h high Quality Bakery Biscuit Making Machine Technology in France |

| 2 | Malaysia 500-700kg/h Easy Operation Biscuit Making Machine |

| 3 | 800kg/h Best Price Biscuit Making Equipment In Germany Factory |

| 4 | Russia 2t/h Energy Saving Automatic Cookie Making Machine |

Biscuits Picture

1. What is the cause of uneven cookie making in the Automatic Biscuit Production Line?

The main factor is the baking oven temperature in the Cookie Production Line. Usually, the baking oven temperature in zone 1 of the Biscuit-making workshop is set too high, which may cause the cookie’s surface to be uneven.

If the gluten of the flour is too high, the cookie’s surface will not be flat and will have a concave bottom.

3. The use of excessive bulking agents in the recipe.

2. What is the effect of the length of mixing time of Industrial Biscuit Making Machine?

The Automatic Biscuit Making Machine makes gluten formation by mechanical kneading and stirring, so the length of mixing time will affect the appearance of gluten and its elasticity. Too short a mixing time will result in insufficient gluten formation, too sticky dough, low tensile strength, and therefore cannot be pressed into a crust, which will result in a less flaky and spreadable final product and affect the quality of the cookie.

Too long mixing time leads to toughness and shrinkage of dough, blurred pattern, rough surface, and air bubbles when processing and molding.

3. What is the process of biscuit processing?

The raw materials of the Biscuit Making Process are mainly wheat flour, sugar, fat, starch, relaxing agent, salt, etc. The finished products of the Biscuit Project are directly affected by the quality of these raw materials and the processing method.

1. Wheat flour: usually use low gluten flour with low ash content and coarse fineness that can pass a 150-micron mesh sieve.

2. Starch: used to dilute the concentration of gluten when the gluten of wheat flour is too high; there is wheat, corn, potato starch.

3. Fats and oils: Biscuit processing requires good shortening and stability of fats and oils.

4. Yeast: Its quality is an essential factor affecting the Biscuit Manufacturing Process, so the cookie-making yeast should perform well.

5. Phospholipids: rationing is generally 5% to 15% of the amount of fat.

6. Loosening agent: tough cookies generally use baking soda and ammonium bicarbonate with a mixture of loosening agents, the proportion of 1% of the powder.

7. Flavoring material: dairy products and salt are used to enhance the Biscuit Project’s nutritional value-rich taste.

8. Spices: usually use banana, orange, pineapple, coconut, and other essential oils; the use of standards needs to meet the requirements of food additives.