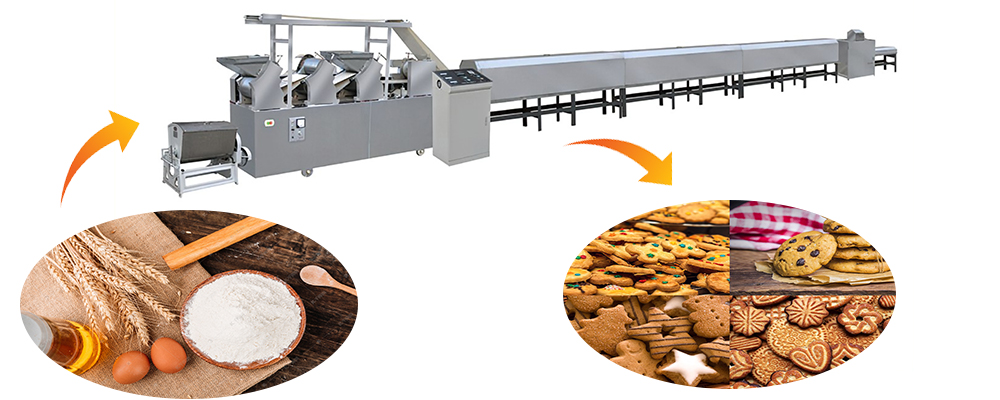

As a professional Small Scale Biscuit Machine Manufacturer, our Small Scale Biscuit Making Machine has a novel design, a compact structure and a high degree of automation, from feeding calendering, forming, waste recovery, drying, oiling and cooling to fully automatic biscuit equipment.

Small Biscuit Making Machine Diagram

The Small Scale Biscuit Making Machine can produce not only crispy biscuits but also tough biscuits. Biscuit Manufacturing Units depending on the mould, different sizes and shapes of biscuits can be obtained, such as cream biscuits, sandwich biscuits, ultra-thin biscuits, soda biscuits, animal biscuits, multi-dimensional biscuits, vegetable biscuits, etc,better to help you develop Biscuit Project.

The Biscuit System has a 0-380 degree rotation function as well as a wire cutting function, Small Scale Biscuit Making Machine which allows the extruded fabric to be rotated through the rotating die and wire cutting die through the gaps in the feed chute to create various patterns of biscuits through different shapes, while maintaining a crispy and tasty taste.

Small Biscuit Making Machine Diagram

The main ingredients of the Small Scale Biscuit Making Machine are:

The main ingredients of biscuits are wheat flour and added accessories such as sugar, fats, eggs and dairy products.

Shortbread biscuits are predominantly indentations with a pinhole surface and a loose texture.

Tough biscuits have a lower ratio of sugar to fats. The sugar ratio is 30% or less and the oil ratio is 20% or less.

The production process of the Small Scale Biscuit Making Machine is as follows

Punching → mixing → fermentation or resting → stacking, rolling → forming → baking → spraying with oil → cooling → packing in plastic baskets → finished product → inspection

Biscuit machinery diagram

What are the advantages of the Small Scale Biscuit Making Machine?

| The Advantages of Small Biscuit Making Machine | |

|---|---|

| 1 | The Cookie Production Line is a forming machine capable of producing a wide range of unique shapes and confections. With its advanced technology, compact structure, easy operation, many functions, and a wide range of applications, it is one of the new Small Cookie Machines ideal for investors in the market today. |

| 2 | The Biscuit Processing Line uses a servo motor plc touch screen control system to ensure that the dough is intact. |

| 3 | The Biscuit Line can be adjusted for product weight and thickness. |

| 4 | The Biscuit Production Line can be configured directly with the biscuit oven to produce extruded, cut and two-color drawn biscuits. |

| 5 | The Biscuit Manufacturing Equipment consists of two main parts, the forming and the bed, which can be adjusted to any speed by means of an infinitely variable speed motor. |

Machine details diagram

Technical data of Biscuit Manufacturing Equipment

| Small Biscuit Making Machine Models | Small Biscuit Making Machine Installation Capacity | Small Cookie Machine Baking Temperature | Small Cookie Machine Production Capability | Small Cookie Machine Length of production line | Small Biscuit Making Machine Price |

|---|---|---|---|---|---|

| LY-1 | 30KW | 200-300℃ | 60~80Kg/h | 20000mm | Us$4,000.00 |

| LY-2 | 60KW | 200-300℃ | 100~120Kg/h | 35000mm | Us$5,000.00 |

| LY-3 | 120KW | 200-300℃ | 190~220Kg/h | 50000mm | Us$5,500.00 |

| LY-4 | 200KW | 200-300℃ | 500~600Kg/h | 60000mm | Us$6,000.00 |

| LY-5 | 240KW | 200-300℃ | 700~800Kg/h | 65000mm | Us$7,500.00 |

2021 Customer Order Small Scale Biscuit Making Machine Maker Form:

| Dealed Customer Have Plant Of Small Cookie Making Machine | |

|---|---|

| 1 | 600kg/h Fully Automatic Small Biscuit Production Line for Japan |

| 2 | America 500-600kg/h Biscuit Making Machine |

| 3 | 2t/h Full Automatic Commercial Biscuit Making Machine for Thailand |

| 4 | 700kg/h Professional Small Biscuit Production Line For Sale In Turkey |

| Dealed Customers Who Repurchase Of Small Cookie Machine At 2021 | |

|---|---|

| 1 | Indonesia 700kg/h high Quality Biscuit Manufacturing Equipment Technology |

| 2 | France 500-700kg/h Easy Operation Cookie Production Line |

| 3 | 600kg/h Best Price Small Biscuit Production Line for Singapore customer |

| 4 | Russia 600-800kg/h Energy Saving Automatic Biscuit Production Line |

Machine details diagram

1. What is the performance of the Small Scale Biscuit Making Machine?

The Small Scale Biscuit Making Machine has a human-machine interface, which makes it easier to set parameters quickly and easily. In addition to the simple drive train, the machine is safe and reliable and easy to maintain.

The Biscuit Production Line is a new generation of biscuits that can be fed directly into a tunnel-type mesh belt baking oven by means of a telescopic arm and can also be used with chain ovens, box ovens and hot air rotary ovens.

2. What is the basic production process of a stamped Small Cookie Machine?

The operation of the Small Cookie Machine is divided into four steps: pressing, printing and forming, sorting, and plating.

1. Slicing: The dough is fed into the biscuit machine for slicing and is continuously pressed by three rollers to form a dense dough strip of uniform thickness.

2. Stamping and forming: the forming part is fed into the machine by a canvas conveyor belt, and the strip of dough is formed into raw biscuit blanks with patterned shapes and remnants by stamping of the model.

3. picking: separating the raw biscuit blanks from the remnants and baking the biscuit blanks that are sent to the steel belt or mesh belt of the baking tray or oven.

4. setting the tray: the remnants are returned by the conveyor belt to the hopper at the front of the biscuit machine, where they are again calendered together with the new input dough.

3. How to properly use a small cookie maker?

1. Read the instructions for the small cookie maker carefully before using it, understand its operation and the precautions to be taken, and follow the instructions strictly.

2. During the operation of the Biscuit Making Machine, do not turn the power off and on too often.

3. Clean up the residue and adhering materials after using the Small Cookie Making Machine in a timely manner to avoid curing the residue and damaging the machine.

4. The Biscuit Making Process needs to go through the links of live material, forming, baking, cooling, etc. Correspondingly, the Automatic Biscuit Production Line can also complete these tasks automatically. The Biscuit Production Line includes a biscuit forming machine, an electric baking oven, an oiling machine, a bending machine, a cooling line, a biscuit finishing machine, a biscuit sandwich machine, a packaging table, etc.