Brazil biscuit making machine customer Mr. Lee is a agent was introduced by a friend at a machine exchange meeting. Mr.Lee is a agent who mainly helps Brazilian end customers purchase biscuit machines, instant noodle machines and many other food machinery. At that meeting, we briefly exchanged some details of the biscuit machine (like the biscuit raw materials, output, and biscuit oven heating type etc,.). After that, we successfully promoted our cooperation mainly through phone calls and face-to-face communication. Finally, The Brazil customer Mr.Lee has purchased two 200kg/h hard and soft biscuit production lines from our Loyal company.

(Hard And Soft Biscuit Production Line)

What Is The Mainly Things That The Customer Concerned?

1.The Suitability Of Raw Materials

The Mr. Lee Brazilian end customer required that the biscuit main raw materials is Tapioca Flour. Due to the cassava is one of the main foods of Brazilians, and has the reputation of “the root of recipes, the root of life” in Brazil. Cassava has become the most distinctive food in Brazil, just like Brazilian barbecue and bean rice. Cassava is rich in starch, minerals and a small amount of protein. What’s more, the Tapioca Flour is cheap and easy to get in their place. In recent years, Brazilians have combined tapioca flour with corn flour and wheat flour to make sweets, biscuits, etc. These kind of biscuits taste more flaky and crispy. Our engineer recommends adding up to 20% tapioca starch, because tapioca starch has a high viscosity, which is not conducive to the forming and de-moulding of biscuits. And final the Brazil Customer and Mr. Lee agreed our suggestion.

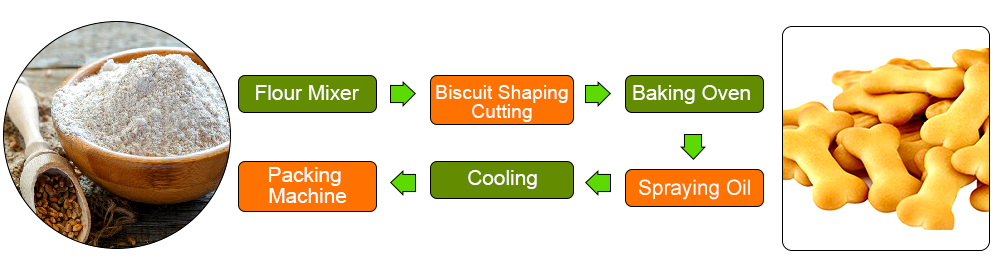

(Automatic Biscuit Manufacturing Processing)

2.The Capacity Of The Hard And Soft Biscuit Production Lines

For the automatic hard and soft biscuit making manufacturing line, we have the capacity like: 50-60kg/h, 100kg/h, 150kg/h, 200kg/h, 500kg/h, etc.

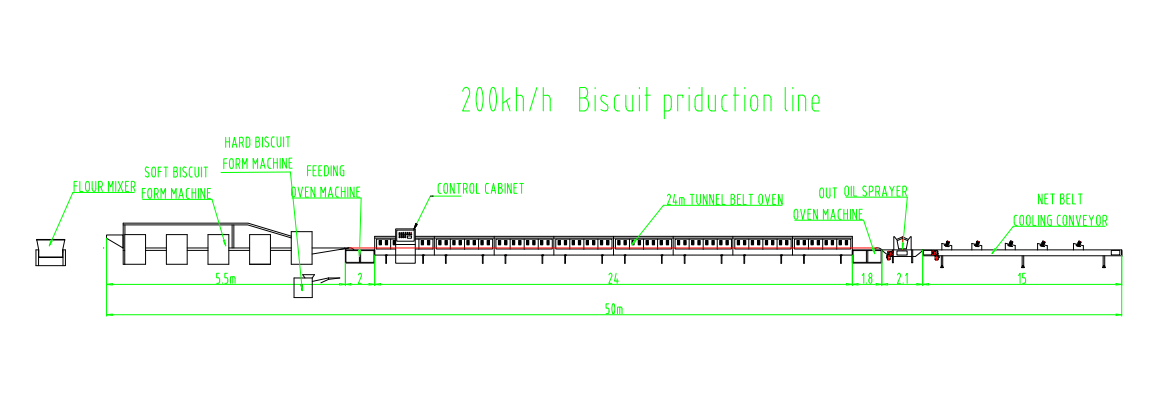

According to the customer factory size and their requirement, we propose a biscuit machine plant–200Kg/h hard and soft biscuit production lines, which placed in a straight line (because the customer’s factory is large enough)

The processing of the biscuit making machine is:

Flour Mixing—Shaping–Baking—Oil Spraying—Cooling–Packing

( Two Line–2ookg/h Hard And Soft Biscuit Production Line Layout)

The Hard And Soft Biscuit Making Machine Equipment List Table:

| The Equipment List Of The Automatic Biscuit Production Line | ||

|---|---|---|

| No. | Automatic Biscuit Making Machine Name | Detail Descriptions Of The Biscuit Machine. |

| 1 | Flour Mixer | To Mixer The Flour With Water Or Something Else, Can Be Used Unique Or With Other Machine. |

| 2 | Hard Biscuit Forming Machine | To Make The Dough Into The Giving Shape,For Processing Hard Biscuit. |

| 3 | Soft Biscuit Forming Machine | Used To Soft Biscuit Forming. |

| 4 | Inlet Oven Machine | Combined The Biscuit Forming Machine With Tunnel Oven. |

| 5 | Intelligent Temperature Control Tunnel Oven | Used To Baking Biscuit. |

| 6 | Outlet Oven Machine | Combined The Oven With Turning Machine, It Is Used For Conveying Baked Biscuit Out Of Oven Smoothly. |

| 7 | Oil Spray | Spay The Oil On The Surface Of The Biscuit . |

| 8 | Food Grade Cooling Conveyor(24 m) | Used For Cooling And Conveying The Biscuits In Normal Condition. |

3.The Operation Of Biscuit Machinery, Installation & Commissioning Of Biscuit Machinery, And The After-Sales Service

( Hard And Soft Biscuit Sample)

Brazilian customers are worried that the hard and soft biscuit production lines is not easy to operate, which is also a concern of most customers. By taking a video for the customer’s on-site test machine, we run the biscuit machine for the customer, thus dispelling the customer’s concerns. Under normal circumstances, only one skilled worker needs to be trained, and 2-3 ordinary workers can assist to complete the operation of the entire line and carry out normal production.

More importantly, we will send a technically reliable and experienced engineer to the customer’s factory to debug machinery, train workers, and make biscuit products according to customer requirements. And we promised we will provide the 12 months warranty.

4.Motor Brands

The Brazilian end customer requires that in order to ensure the smooth production of the hard and soft biscuit production lines in the later stage, the motor brand of the machine requires a well-known brand.

ABB Motor Of Hard and Soft Biscuit Making Machine

| Parameter Of Abb Motor For Hard And Soft Biscuit Making Machine | ||

|---|---|---|

| 1 | Package Level 1 Units: | 0 Carton |

| 2 | Product Name: | 3-Phase Squirrel Cage Motor |

| 3 | Product Net Weight: | 5.9 Kg |

| 4 | Product Type: | 3Aa2__M3Aa_Ie2_Aa |

| 5 | Scip: | 27ac6190-e1ce-4080-8654-6552aaabbe58 Finland (Fi) |

| 6 | Selling Unit Of Measure: | Piece |

| 7 | Standards: | Iec 60034-1 |

| 8 | Starting Of Motor: | Direct Online |

Finally, after 2 months of stable and continuous communication, the Brazilian customer successfully ordered 2 hard and soft biscuit production lines from our loyal company. We expect to arrange delivery to customers within 35 working days.