As a professional Biscuit Machine Manufacturer , our company has been adhering to the concept of professional exploration of Biscuit Machine Technology , aiming to bring more and better quality Cookie Maker products to the cookie industry. The whole line of Automatic Biscuit Machine adopts CPU module control, back-mounted motor drive, compact structure and high degree of automation, and is sold all over the world.

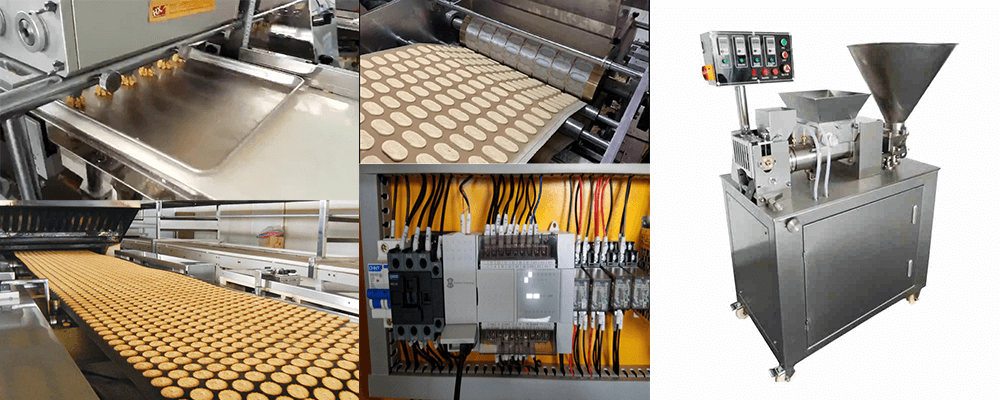

Biscuit Mechanical Drawing

Breakfast Cookies contain a large number of calories required for general human activities and various trace elements that promote metabolism, so they are the main biscuits in this period of breakfast. The vitamin group rich in Breakfast Biscuits can promote the pituitary gland to secrete various exciting body fluids, which can promote human energy. In addition, Breakfast Biscuits also has dietary fiber that promotes gastrointestinal motility, but it cannot be eaten for a long time. Otherwise there is a risk of gaining weight.

cookie chart

Biscuit Project ?

| Types of Cookie Items | ||

|---|---|---|

| 1 | soda crackers | The sugar and oil content is less. First, yeast is added to a part of the wheat flour, and then it is made into a dough. After a long time of fermentation, the rest of the wheat flour is added, and then it is formed after a short time of fermentation. |

| 2 | graham crackers | has not been removed from the bran and are ground into flour. The color is darker and the taste is rougher. It retains a lot of vitamins, minerals, and cellulose in the bran, and has higher nutritional value. |

| 3 | sandwich biscuits | It belongs to high-calorie biscuits, with high fat and sugar content, more accessories, and other flavors such as milk, eggs, and jam. |

| 4 | Nutritionally fortified biscuits | The most common variety is to strengthen minerals and vitamins, such as calcium, iron, zinc, vitamin A, vitamin D, etc., and some add wheat bran, which belongs to increasing dietary fiber. |

Cookie Production Line ?

| Advantages Of Automatic Biscuit Production Line | |

|---|---|

| 1 | Biscuit Manufacturing Equipment can adjust the thickness of biscuits arbitrarily, and Biscuit Machine mechanical transportation is step less speed regulation, which can adjust the speed arbitrarily, greatly improving production efficiency. |

| 2 | Automatic Biscuit Plant uses imported components and electrical appliances, with high thermal energy utilization rate, which can save energy and cost. |

| 3 | Hundreds of molds and recipes are distributed, and any popular biscuits on the market can be produced. And Cookie Production Line can produce both tough biscuits and crispy biscuits through a dual-purpose machine head. |

| 4 | Automatic Biscuit Production Line has a compact and precise structure and a high degree of automation. It can realize a series of biscuit production line processes such as automatic constant temperature, baking, transportation, oil injection, and cooling, saving labor costs and easy operation. |

Biscuit Mechanical Drawing

The company’s Cookie Maker overseas market is still in a state of continuous expansion. Biscuit Machine is in an advantageous position in external sales and sales, and has established extensive contacts with overseas customers. Biscuit Machine Technology can be adjacent to foreign technologies.

2021 Customer Order Biscuit Making Machine For Factory Case:

| Cookie Making Machine ‘s Trading Client Case | |

|---|---|

| 1 | 400kg/h Automatic Electric Industrial Biscuit Making Machine for sale in Canada |

| 2 | 7 00- 8 00kg/h Automatic Biscuit Making Machine for sale in India |

| 3 | 2 t/h Bakery Biscuit Making Machine sold in South Africa |

| 4 | 8 00kg/h Professional Automatic Biscuit Making Machine sold in Japan |

| Full Automatic in 2021 Customer Stories of Small Cookie Making Machine | |

|---|---|

| 1 | Germany sells 5 00kg/h high quality Biscuit Making Equipment |

| 2 | 3 00- 5 00kg/h Industrial Biscuit Making Machine for sale in USA |

| 3 | Spain sells 7 00kg/h Biscuit Making Machine For Factory with high cost performance |

| 4 | t/h energy efficient Biscuit Manufacturing Equipment for sale in Italy |

If you have any questions about Automatic Biscuit Making Machine feel free to contact our Biscuit Machine Manufacturing Technology team, we can provide you with a complete service and look forward to working with you.

1.What to look for when buying cookies?

1.Distributors in larger shopping malls and supermarkets have stricter control over the purchase channels, and the quality of Biscuit Products is guaranteed.

2.Check the Biscuit Project label to see if the factory name, address, phone number, and whether the implementation standards are complete , and whether the product is within the warranty period. Pay attention to whether the “QS” logo is affixed on the product. Whether the ingredient list is detailed , and the situation of food additives.

3.Check whether the packaging of Biscuit Products is damaged and whether there is moisture in the inner layer of the packaging to prevent the product from being damp and moldy .

4.Pay attention to the preservation conditions. Good-quality biscuits should have a complete shape, clear patterns, no shrinkage or deformation, and have the unique crispiness and crispiness of the product. It should be eaten as soon as possible after opening the package, and stored in an airtight container in a cool, dry place if not consumed at one time.

2.How to deal with defective cookies?

1.Develop a new Biscuit Project to produce from defective products; or add sandwich products to existing products.

2.Defective Cookies can be crushed and ground finely, or can be ground into a paste with water, added when kneading or mixing, or added to the sandwich cream .

3.Defective Biscuit is simply packaged and sold cheaply in remote markets through small vendors.

4.Can be sold to feed mills or farmers.

Either way, it is necessary to pay attention to Biscuit Project ‘s food safety and hygiene conditions to avoid foreign matter entering the product and endangering the health of consumers.

3.Why is Biscuits Finished soft or brittle?

Soft biscuits: Biscuit Project itself is too thick and the temperature in the Biscuit Making Plant oven is too high and the baking time is too short, causing the outside to be charred and the inside to be raw, and the inside of the biscuits to have too much moisture. The thickness of the biscuits should be controlled, the temperature of the oven in the Biscuit Processing Line should be appropriately lowered , and the baking time should be increased.

Crumbly biscuits: Excessive puffing of the biscuits, making the Biscuit Manufacturing Process gluten too loose; or adding too much starch and cookie crumbs. The amount of leavening agent, starch and biscuit crumbs should be appropriately reduced.

Breakfast biscuit production line Vido